Vector controller based on software dead-time compensation

A vector controller and dead zone compensation technology, applied in vector control systems, control electromechanical brakes, control systems, etc., can solve the problems of output current waveform distortion, PMSM torque ripple of permanent magnet synchronous motor, motor oscillation, etc. Small distortion, improve stability and reliability, and ensure the effect of effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

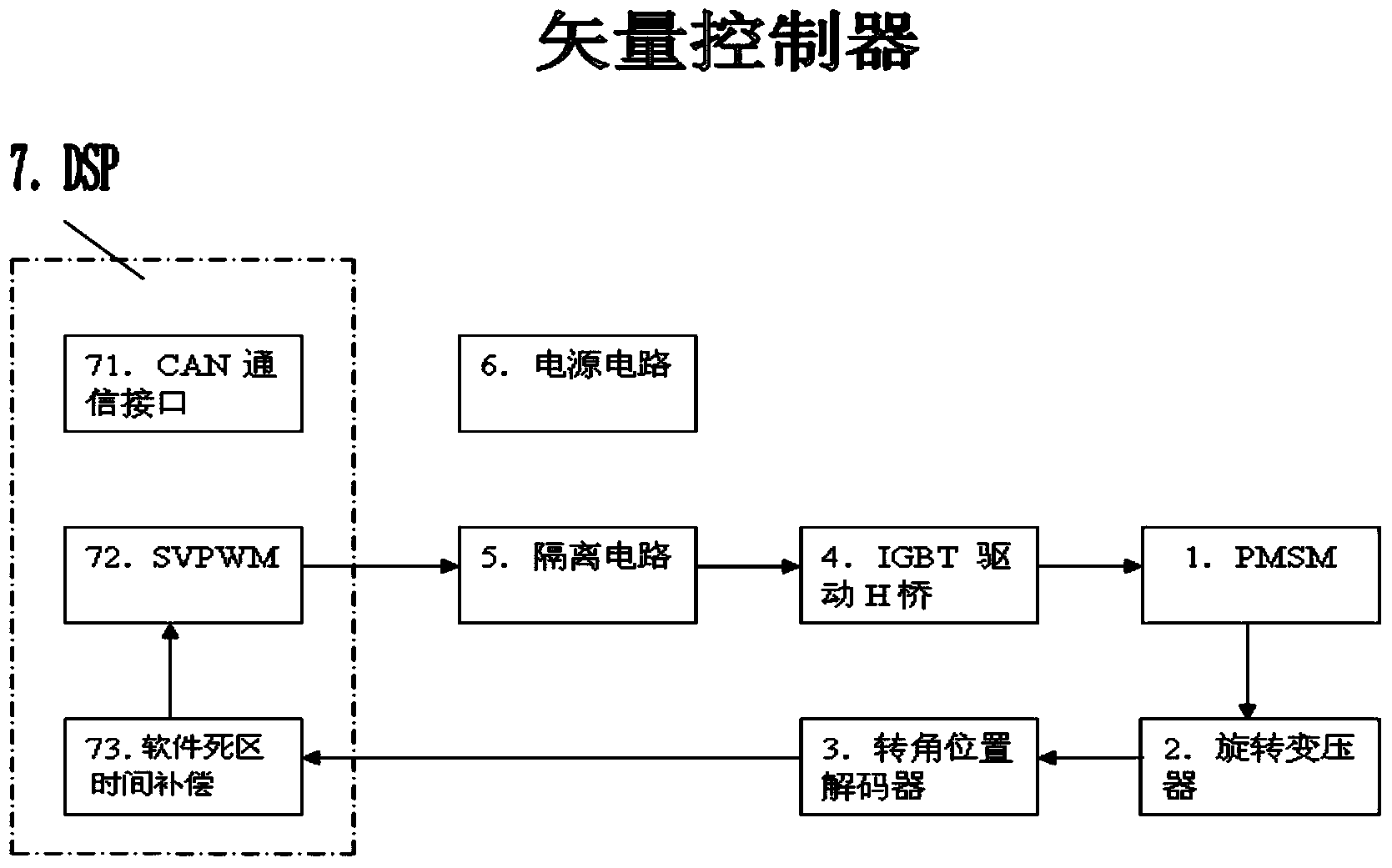

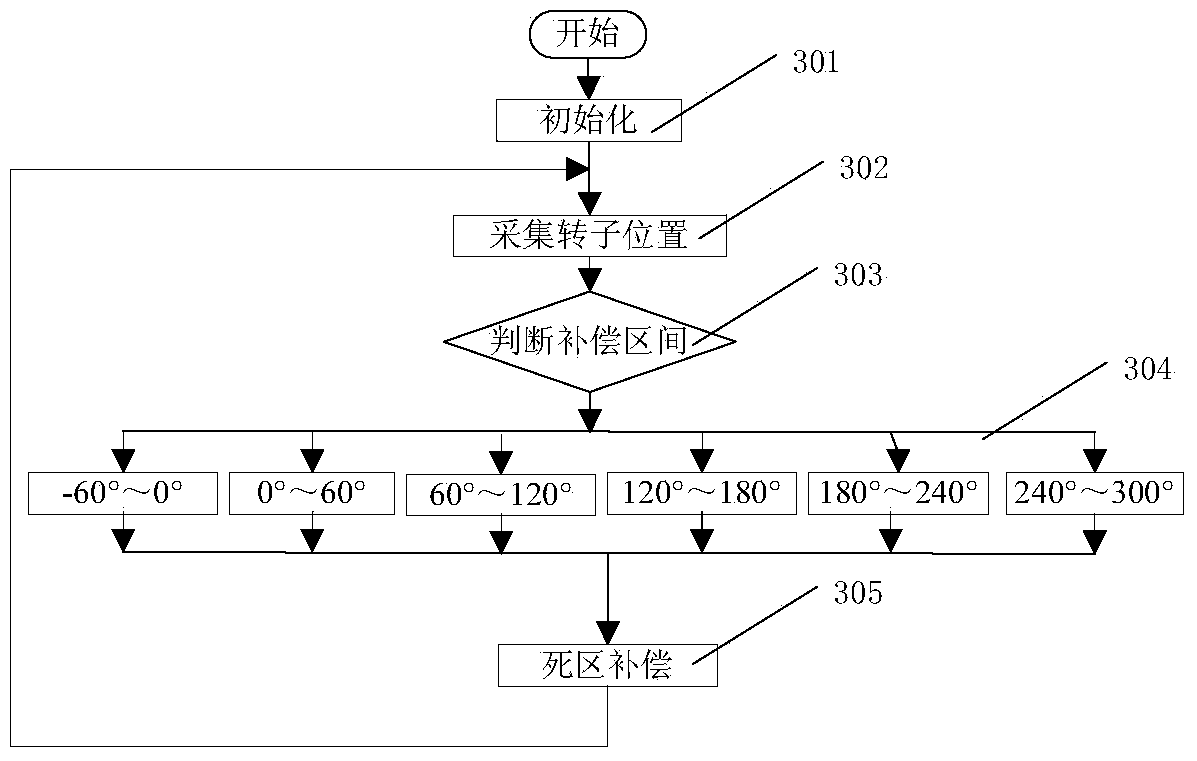

[0024] First, if figure 1 As shown, the vector controller based on software dead zone compensation includes digital signal processor DSP7, permanent magnet synchronous motor PMSM1, resolver 2, corner position decoder 3, IGBT driving H-bridge 4, isolation circuit 5 and power supply circuit 6, Described DSP7 comprises software dead zone compensation algorithm 73, space voltage vector pulse width modulator SVPWM72 and CAN communication interface 71; Wherein, described IGBT drives H bridge 4 and described permanent magnet synchronous motor PMSM1 is connected to described permanent magnet synchronous The motor PMSM1 is driven and controlled; the rotary transformer 2 is connected with the permanent magnet synchronous motor PMSM1 to detect in real time the angular position of the rotor of the permanent magnet synchronous motor PMSM1; the angular position decoder 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com