Dilute acid filtering device and using method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

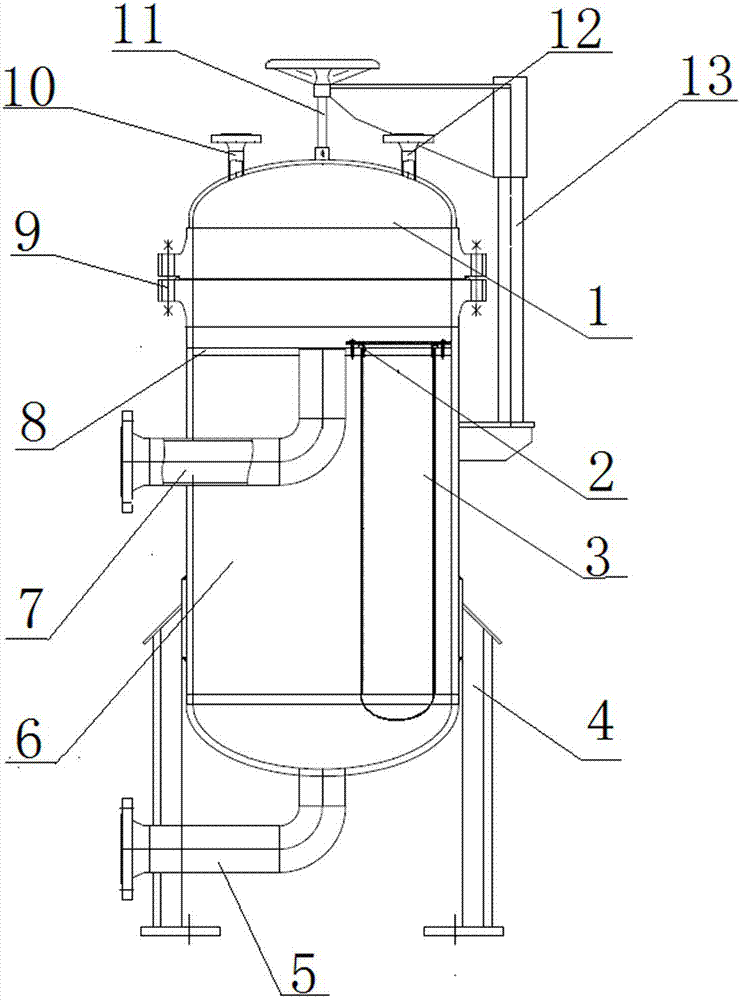

[0024] Embodiments of the present invention are as follows: figure 1 As shown, the dilute acid filter device includes a tank body 6, a cover body 1 is arranged on the upper end of the tank body 6, and an exhaust port 10 and a pressure gauge port 11 are arranged on the cover body. A partition 8 is installed in the cavity of the tank body, which divides the tank body into two parts, the upper part is the liquid inlet chamber, and the lower part is the filter chamber. The dilute acid inlet pipe enters from the bottom of the partition 8, and connects to the liquid inlet chamber from below through the holes on the partition 8. A liquid outlet pipe 5 is arranged at the bottom of the filter chamber of the tank body 6, and a filter recovery unit 2 is installed on the partition plate 8 of the inner wall of the tank body 6, and the filter recovery unit 2 is connected by a filter bag Plate, the filter bag installed on the filter bag connecting plate and the net bag 3 fixed outside the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com