Preparation method of heatable sandwich type purification material

A purifying material, sandwich technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of low strength, weak bonding of base cloth, large pressure drop of composite filter materials, etc., and achieve high tensile strength. , The fiber diameter is small, and the effect of improving the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] An embodiment of the present invention provides a method for preparing a heatable sandwich-type purification material, the method comprising:

[0014] Add cross-linking agent A to the conductive carbon paste and apply it to the glass fiber mesh cloth, and then cross-link and solidify to form a heating net;

[0015] Electrospun polymer nanofibers onto industrial filter cloth to make filter base cloth;

[0016] Add cross-linking agent B to the insulating slurry and apply it on the heating net, press the heating net coated with the insulating slurry and the filter base cloth together, and obtain a sandwich-type purification material that can be heated after cross-linking and curing.

[0017] In the above method, the conductive carbon paste is: using methyl vinyl silicone rubber raw rubber, conductive carbon black and solvent A as raw materials, and mixing them by mechanical stirring to make a conductive carbon paste with uniform dispersion of carbon black;

[0018] The in...

Embodiment 1

[0030] Example 1 Weigh 25g of methyl vinyl silicone rubber raw rubber (M=600000, vinyl content 0.15mol%), put it into a three-necked flask, add 100g of xylene to it, set up a stirring device and a reflux device , start stirring at 60°C, and add xylene from time to time. After the raw methyl vinyl silicone rubber is dissolved, add 7.5g of carbon black in proportion to the three-necked flask, continue stirring, and add 80g of xylene, and wait for the solution After uniformity, stop the reaction and let it stand for cooling to make PTC carbon slurry, then add a certain amount of benzoyl peroxide (BPO) to the carbon slurry, mix it evenly, and apply it to the mesh by dipping On the glass fiber mesh cloth with a size of 10×10mm, through drying at room temperature and vacuum drying at 150°C, the raw methyl vinyl silicone rubber in the carbon slurry is cross-linked to produce a heating net with evenly distributed carbon slurry.

Embodiment 2

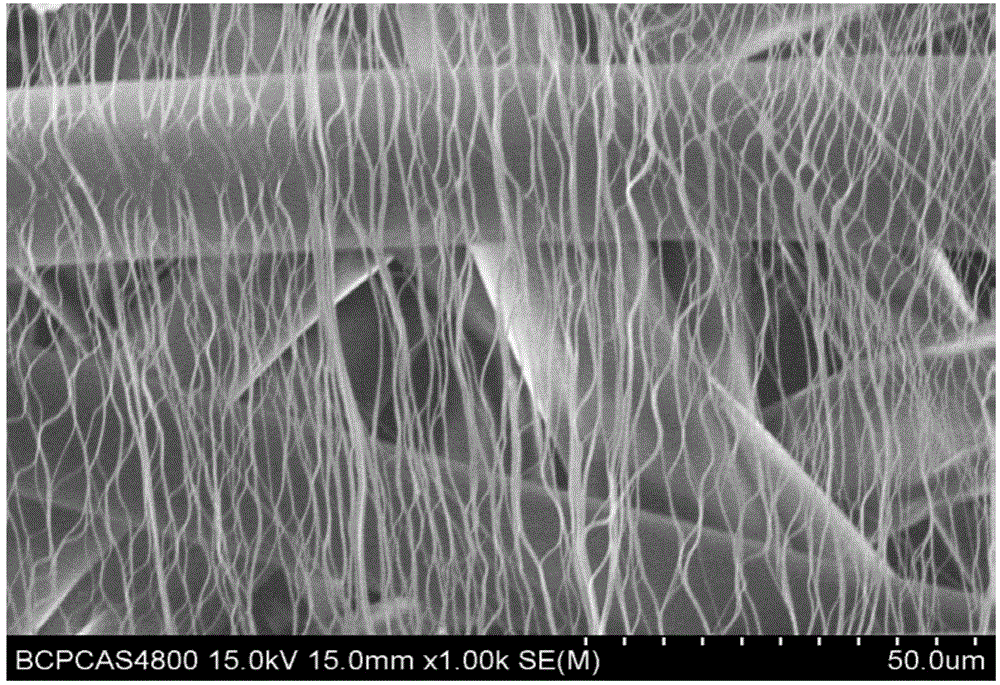

[0031] Example 2 Dissolve 5.2g of PA-6 in 34.8g of formic acid. After sealing, use magnetic stirring for 12 hours to fully dissolve it, configure it into a 13wt% PA-6 / formic acid solution, and use a self-designed electrospinning device to spin Under the conditions of voltage 15kV and receiving distance of 10cm, PA-6 nanofibers were electrospun onto washed industrial filter cloth to make filter base cloth, and the industrial filter cloth collected with PA-6 nanofibers was fully dried. The SEM image of the industrial filter cloth with PA-6 nanofibers collected is shown in Figure 1. It can be seen from the figure that the PA-6 nanofibers are evenly distributed on the industrial filter cloth, and the average diameter is 80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com