Bearing part hydrocarbon cleaning device

A technology for hydrocarbon cleaning and parts, applied in lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of high design difficulty and complexity, reduce smoothness, parts damage, etc. Use fit and flexibility, reduced tightness requirements, simple delivery structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

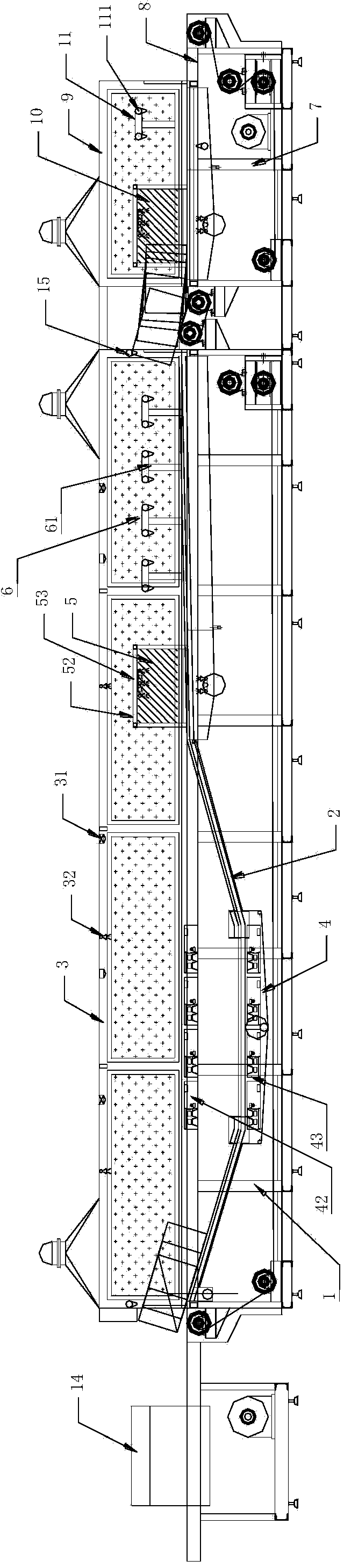

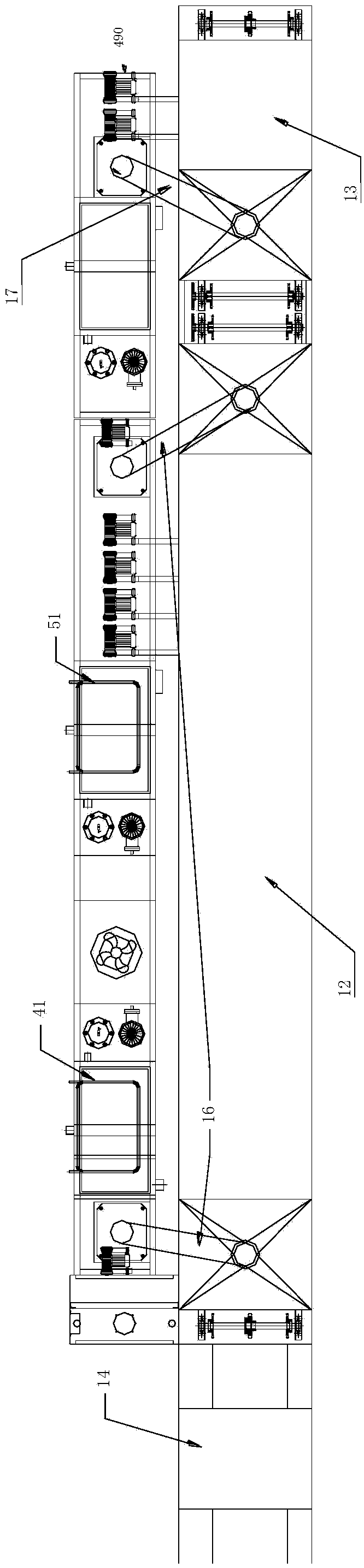

[0037] like Figure 1-2 As shown, the hydrocarbon cleaning equipment for bearing parts in this embodiment includes a main frame 1, the upper surface of the main frame 1 is provided with a main conveyor belt 2 extending along the upper surface of the main frame, and a main transparent cover is provided above the main frame 1 3. The main transparent cover 3 is provided with an ultrasonic cleaning assembly 4, a spray rinsing assembly 5, and a spray drying assembly 6 in sequence along the running direction of the main conveyor belt 2. The end of the main frame 1 is provided with a sub-frame 7. The auxiliary frame 7 is provided with a secondary conveyor belt 8 extending from the upper surface of the secondary frame 7, and a secondary transparent cover 9 is arranged above the secondary frame 8. In the secondary transparent cover 9, the running direction of the secondary conveyor belt 8 is successively provided with a spray protection device. Rust component 10 and antirust drying com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com