Multicutter device of tile cutting machine

The technology of a tile excavator and a tool is applied in the field of processing devices of sintered NdFeB permanent magnet materials, which can solve the problems of low efficiency, affecting product qualification rate and yield, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

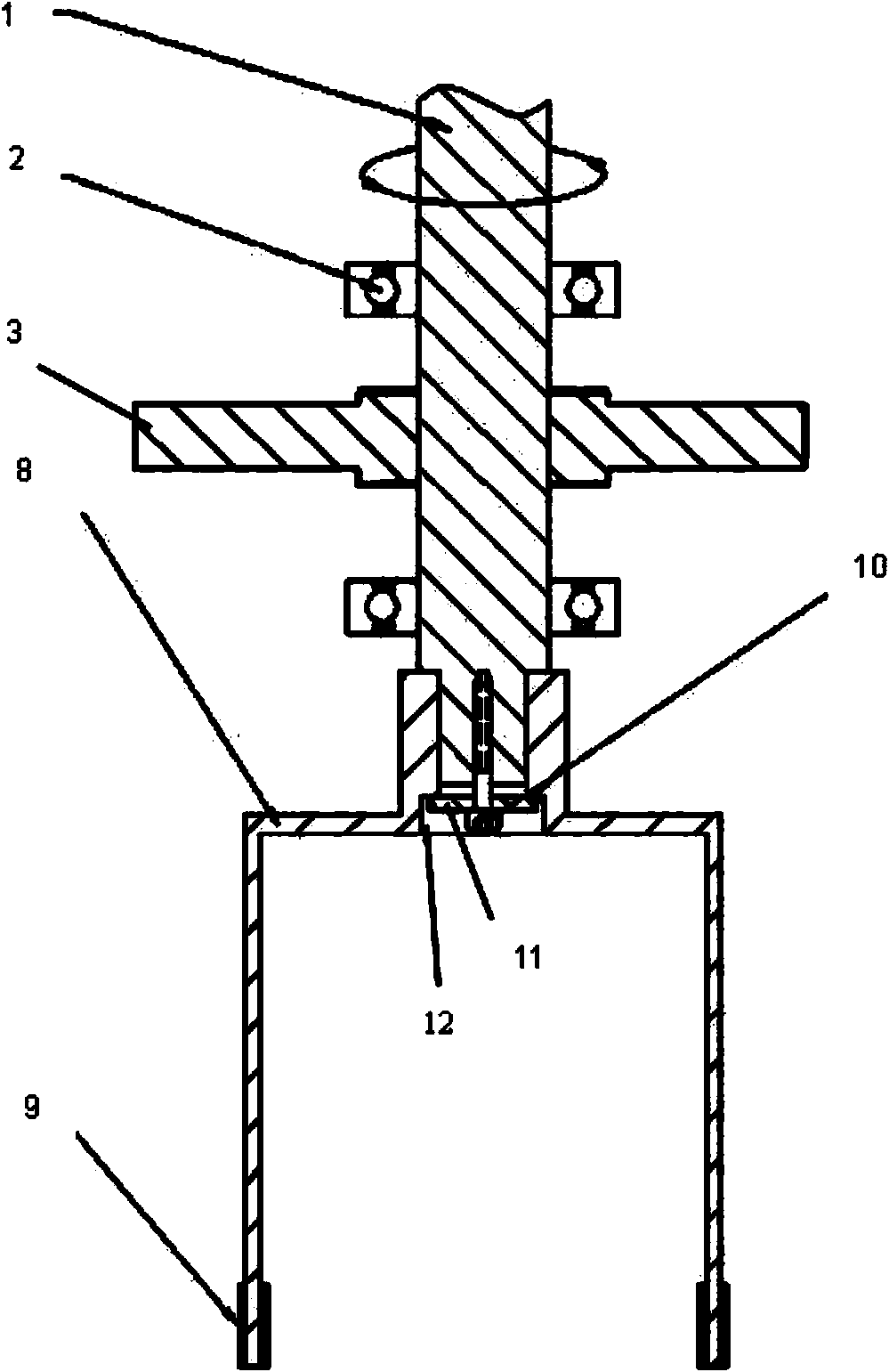

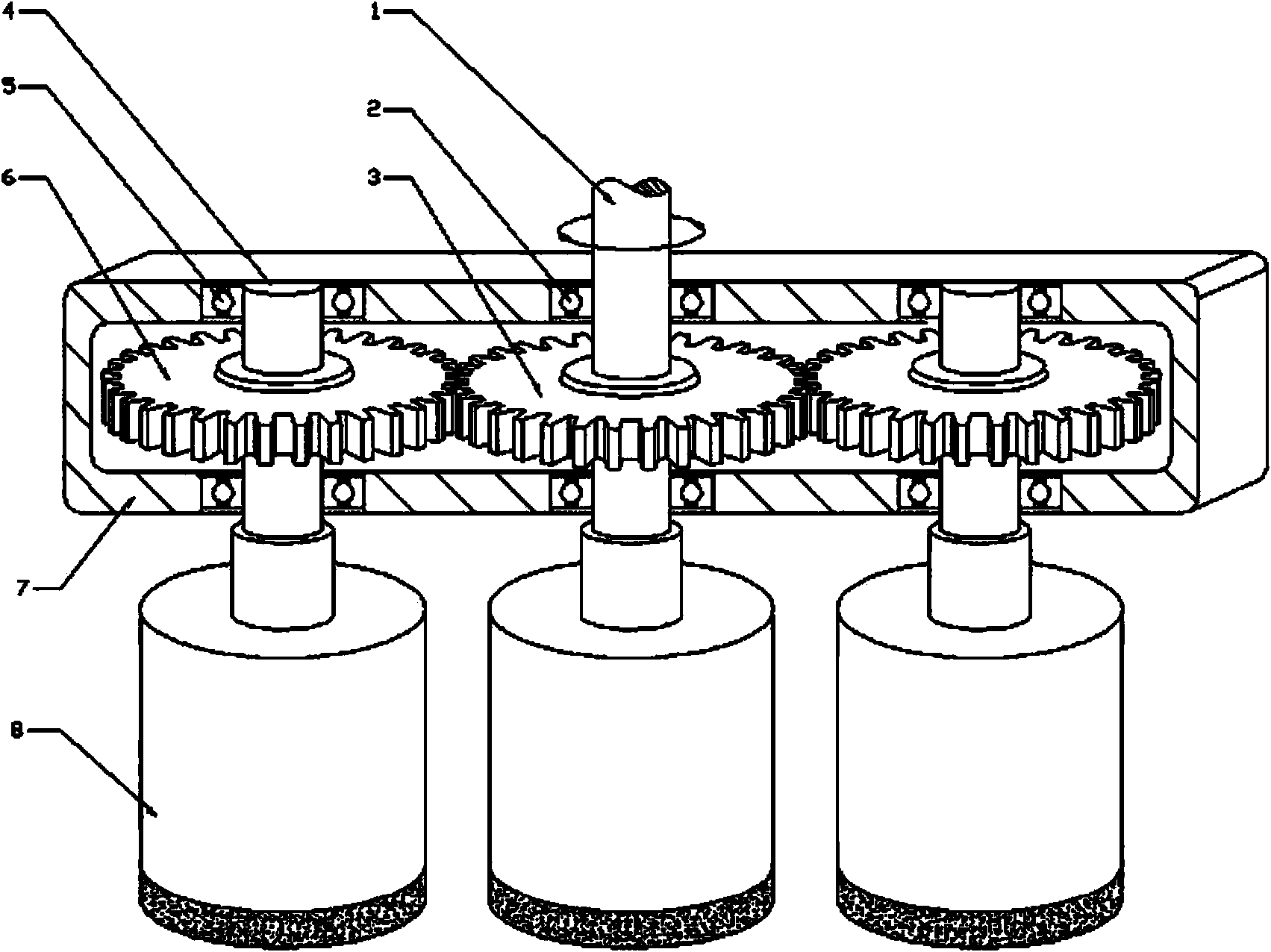

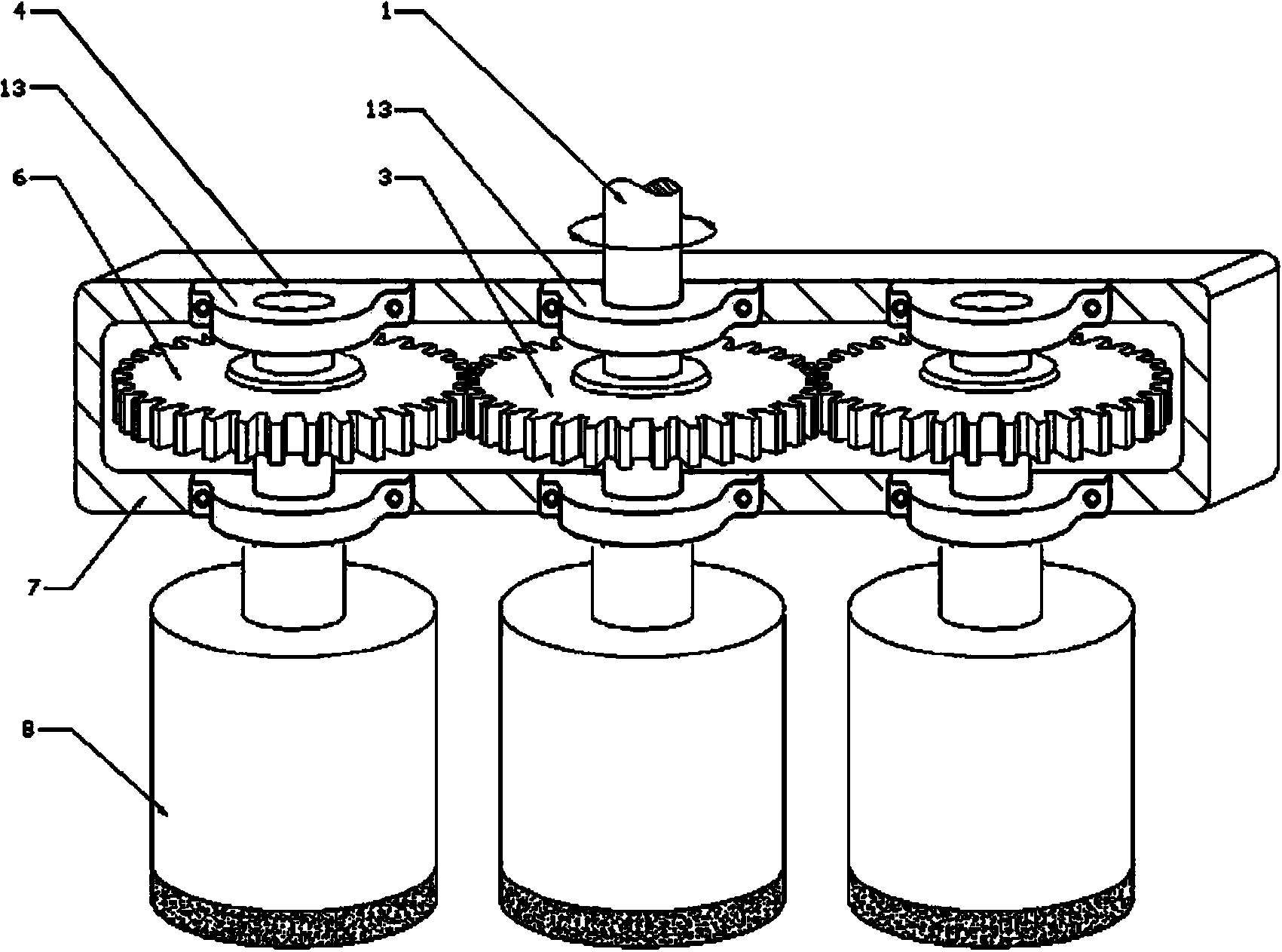

[0014] Such as figure 2 It can be seen that the present invention provides a multi-cutter device for a tile removal machine, which includes a removal tool 8, a bearing, a rotating shaft, a gear and a gearbox 7, and the rotating shaft is divided into a driving shaft 1 and a driven shaft 4. figure 1 It is a cross-sectional view of the drive shaft connection of the multi-cutter device of the tile removal machine according to the present invention. As can be seen from the figure, the removal tool 8 is a "convex" longitudinal section formed by combining two cylinders with different outer diameters. Glyph-shaped cylinder body, the upper cylinder body is provided with internal threads, and the interior of the connecting turning point with the lower cylinder body is provided with st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com