Silicon rod with chamfered guide strip

A technology of guide strips and silicon rods, applied in the field of silicon rods, can solve the problems of easy slippage of steel wires, uneven thickness of silicon rods, and wire pressing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

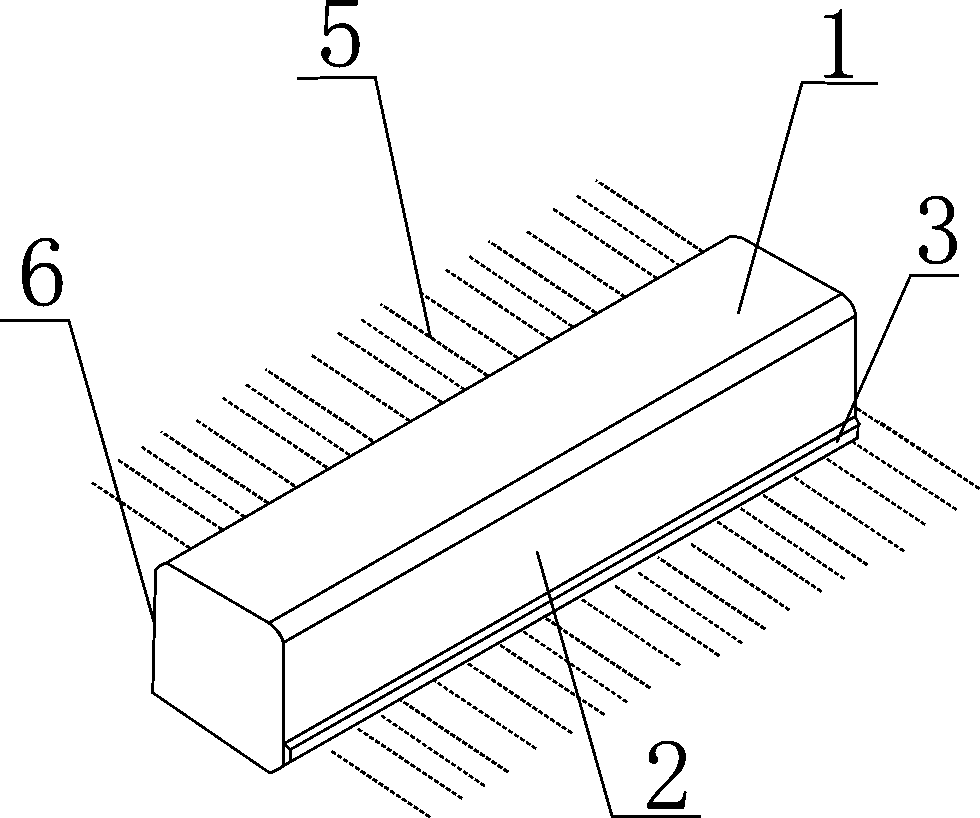

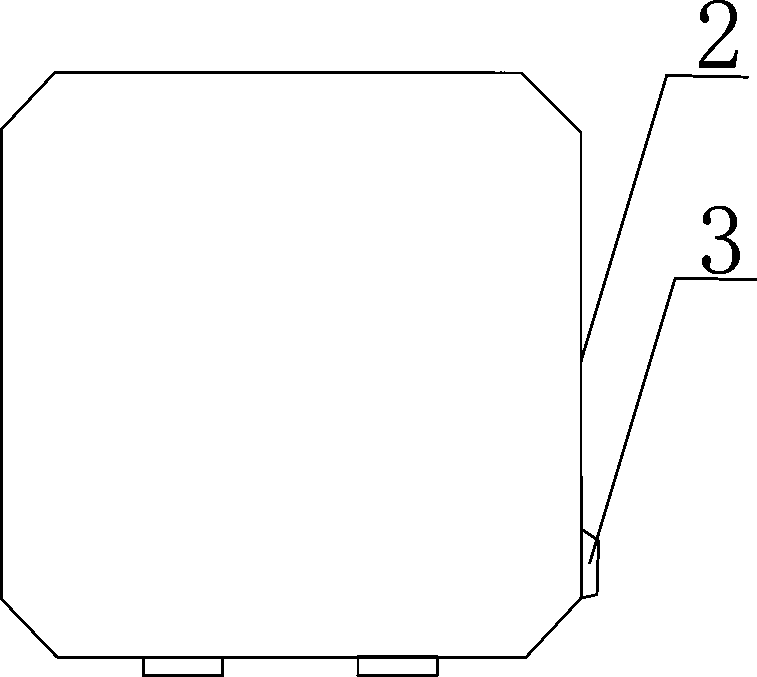

[0014] Such as Figure 1~Figure 4 As shown, a silicon rod provided with a chamfering guide strip, the first side 2 of the silicon rod 1 is provided with a guide strip 3, and the first side 2 is the first contact surface of the steel wire feeding.

[0015] The guide strip 3 is bonded to the first side 2 of the silicon rod 1, and the bonding position of the guide strip 3 is parallel to the edge 4 at the chamfer of the silicon rod 1; parallel.

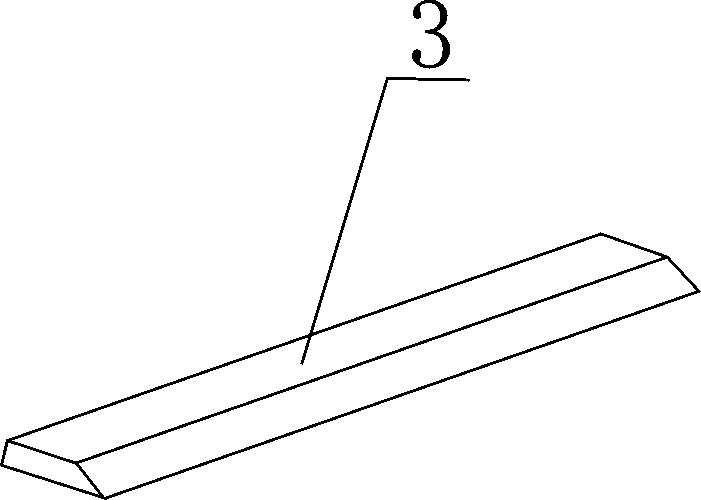

[0016] The guide strip 3 is trapezoidal, the thickness of the trapezoid is 1-10mm, and the length of the shorter bottom side of the trapezoid is 1-156mm.

[0017] The guide strip 3 is any one of PPS, PMMA, PEEK, PET, PVC, PPO, PS, PC, PES or PASU general engineering plastics.

[0018] There is at least one guide bar 3 .

[0019] The present invention is a silicon rod provided with chamfering guide strips. During the cutting process, when cutting to a certain depth, the chamfering is cut, and the wire net 5 To form a wire bow, the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com