Four-corner leveling device of novel rapid hydraulic machine

A technology of four-corner leveling and hydraulic press, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unbalanced loading of pressed workpieces, increase of production costs, inconsistent product thickness, etc., and achieve the effect of preventing unbalanced loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

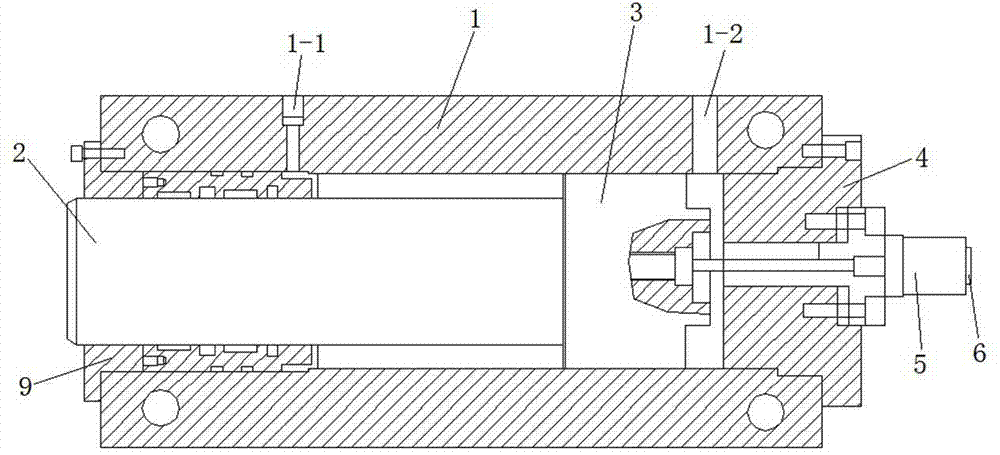

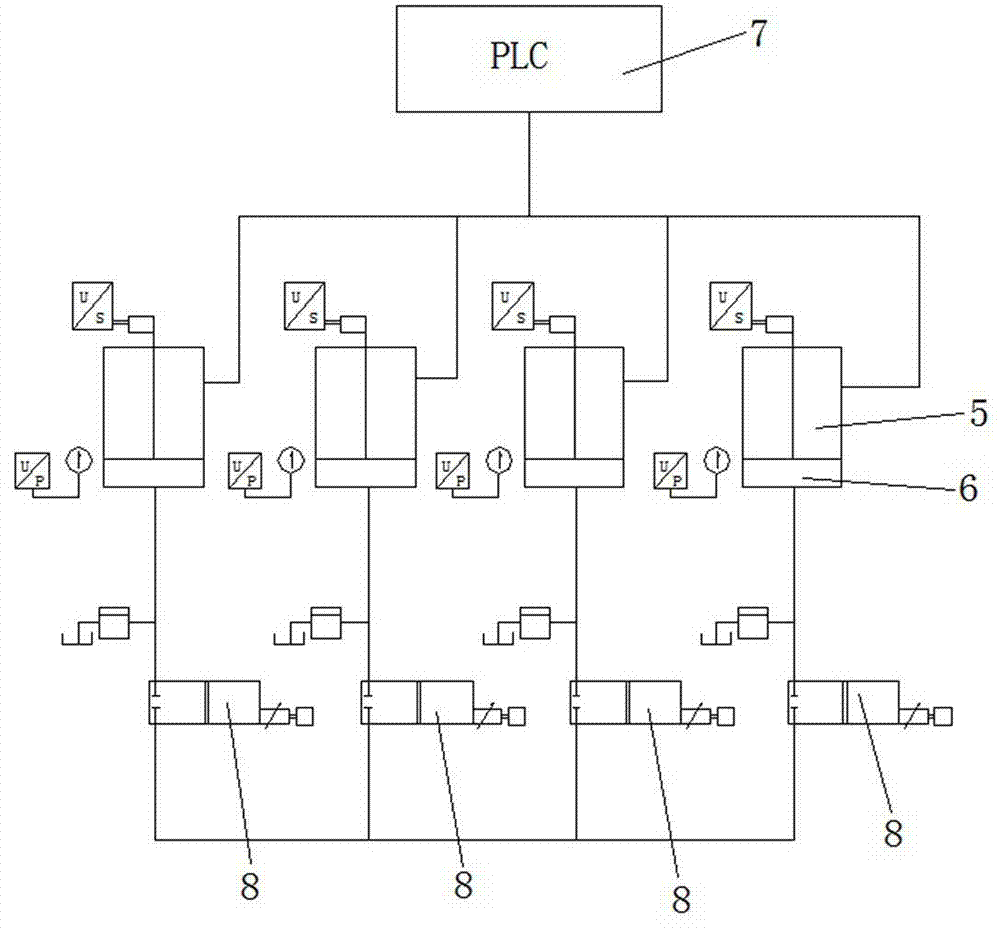

[0012] Such as figure 1 , figure 2 As shown, the four-corner leveling device of the new fast hydraulic machine includes an oil cylinder 1, a piston rod 2, a piston 3 and a flange 4, and a leveling cylinder 5 is provided under the piston 3, and the leveling cylinder 5 is fixedly installed on the hydraulic machine The four corners of the lower end of the fuselage, the bottom of the leveling cylinder 5 is provided with a displacement sensor 6, and the displacement sensor 6 is connected with the control assembly. Wherein, the displacement sensor 6 is a digital displacement sensor, and the digital displacement sensor can directly send signals to the computer system, and the collected data is accurate and reliable. In this embodiment, when the sliding block assembly of the hydraulic press is about to be combined with the downward mold, the adjustable screw rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com