Hybrid power system for controlled vehicles

A composite power supply and vehicle technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of volatilization of adhesives in interior parts, inability to produce air convection, harmful gas hazards, etc., and achieve low cost , saving power costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

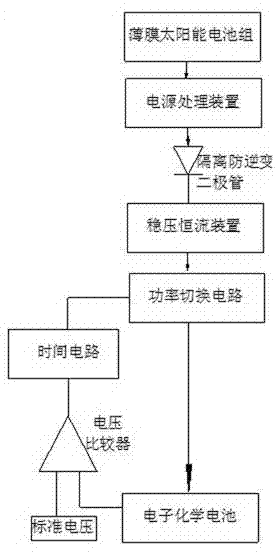

[0023] For the composite power supply of controlled vehicles such as commercial large vehicles or engineering machinery, the thin-film solar battery pack is connected with a power processing device, and the power processing device is connected in series with a constant voltage constant current device and a power switching circuit, and finally connected to the battery; the power switching circuit and A loop is connected in parallel outside the battery, and a time circuit and a voltage comparator are connected in series in the loop, and the voltage comparator is respectively connected to the battery and a standard voltage power supply.

[0024] The time circuit is turned off after a 10-minute delay when the battery is sufficient, and then restarted after 30 minutes, and starts immediately when the voltage drops.

[0025] An isolation anti-inversion diode is connected in series between the power processing device and the voltage stabilizing and constant current device.

[0026] T...

Embodiment 2

[0030] The implementation plan design for the car is: 1.5W / 140mA, 18v thin-film solar group connected in series to prevent reverse current, connected in series with supercapacitor and connected in parallel with 70% of the original battery capacity battery pack, which not only ensures that the weight of the vehicle does not increase, but also provides the temperature control switch and ventilation fan for the vehicle. Power supply, the power supply current is about 3A, and the fan is automatically turned off when the temperature inside the car is equal to the ambient temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com