Steel wire strip horizontal aeration brush

A steel wire, aeration technology, applied to mechanical aeration. It can solve the problems of high oxygen diffusion resistance and different oxygenation capacity, and achieve the effect of promoting diffusion, complete oxygenation, and promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

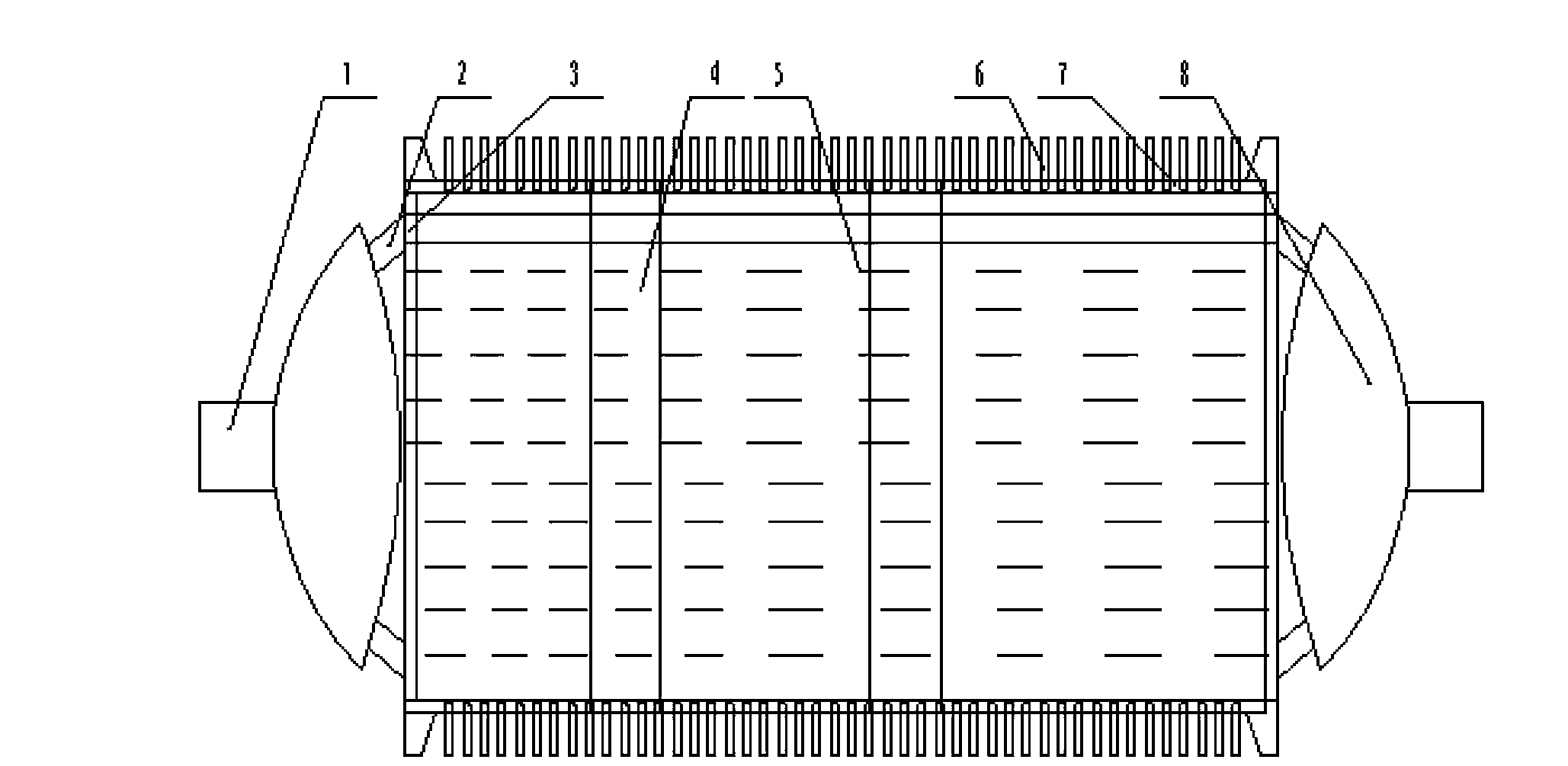

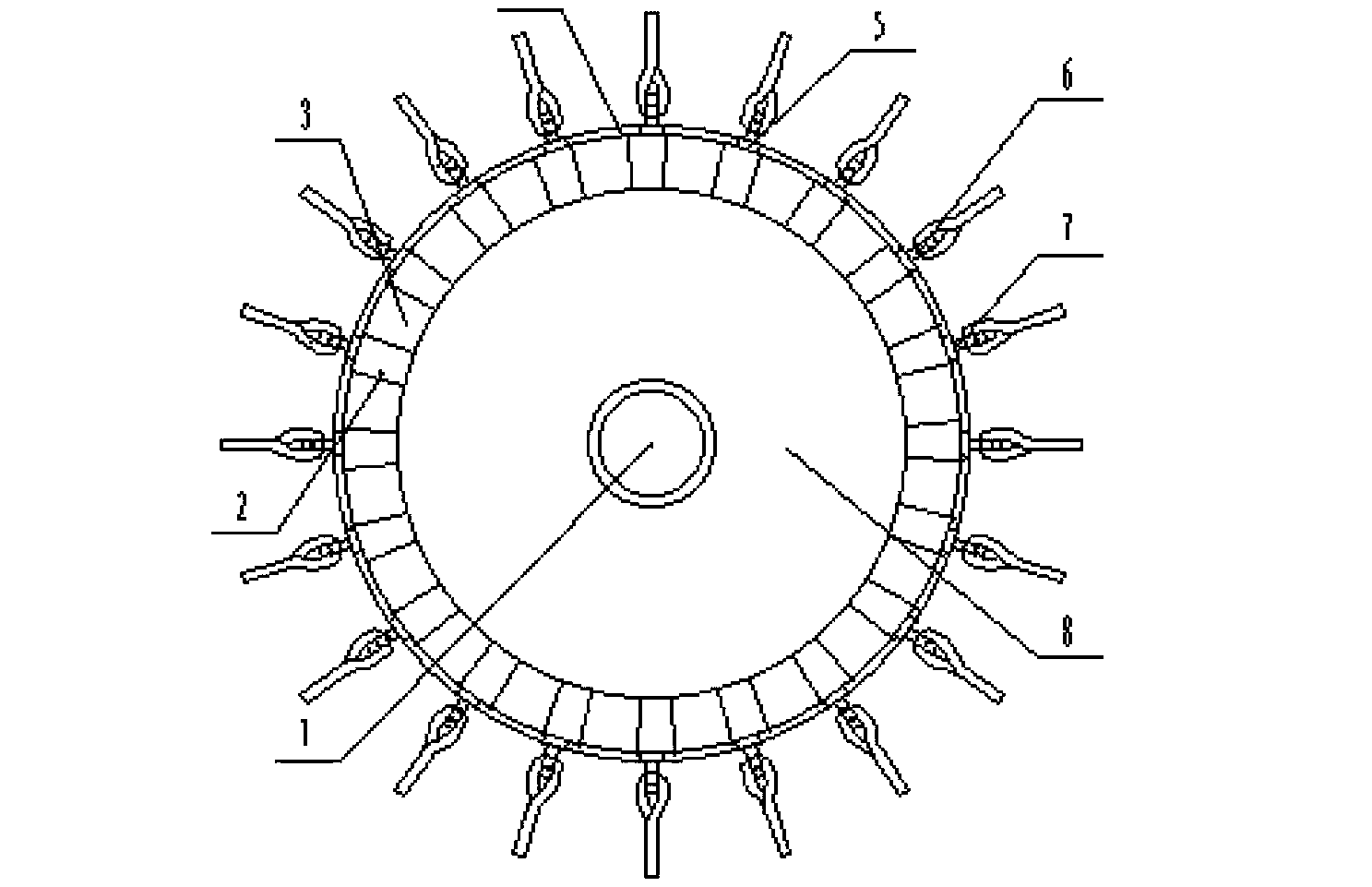

[0010] Such as figure 1 and figure 2 As shown, the steel wire horizontal aeration brush includes a rotating shaft 1, a fan-shaped rib plate 2, an annular end plate 3, a cylindrical reinforcement ring 4, a longitudinal rib plate 5, a steel wire bar 6, a base 7, and an arc-shaped end cover 8 , the rotating shaft 1 is connected with the arc-shaped end cover 8, the arc-shaped end cover 8 is connected with the fan-shaped rib plate 2, the fan-shaped rib plate 2 is connected with the annular end plate 3, the annular end plate 3 is connected with the longitudinal rib plate 5, and the longitudinal rib plate 5 is connected with the cylindrical reinforcing ring 4, the cylindrical reinforcing ring 4 is connected with the base 7, the base 7 is connected with the steel wire 6, and the steel wire 6 is made of a stainless steel wire with a diameter of 8mm in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com