Grey cashmere discoloring method

A technology of green velvet and soft water, applied in the field of decolorization of plush, can solve the problems of long decolorization time, low production efficiency, time-consuming and laborious, and achieve the effect of short decolorization time and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

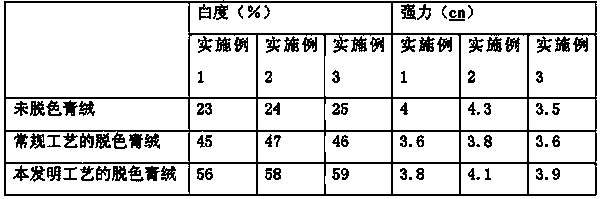

Embodiment 1

[0072] A method for decolorizing green velvet, comprising the following steps:

[0073] ①. Enzyme washing: Put the green velvet into the loose wool dyeing vat at room temperature, add soft water, the bath ratio is 1:10~15, stir, and then add 2% (owf) non-ionic lotion (FK-9508D1, China Textile Chemical Co., Ltd. ) and 0.1% (owf) sererinase (cta-b, China Textile Chemicals) soaking treatment, adjust the pH value to 8; increase the temperature by 2°C per minute to 55°C, maintain for 15 minutes, empty the mixed lotion; wash once ;

[0074] ②. Pretreatment: add soft water to the green velvet washed in step ①, stir, adjust the pH value to 5, add 5% (owf) of hydrosulfite in turn, add 1% (owf) complexing agent, 2.5% (owf) FeSO 4 ;Increase the temperature by 3°C per minute to 55°C, keep it warm for 60 minutes, empty it, and wash it once with water;

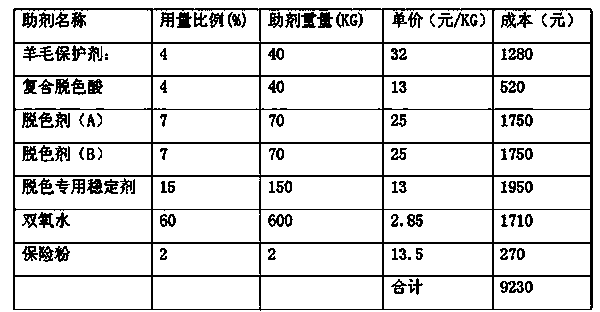

[0075] ③. Oxygen bleaching: step ② add soft water to the washed green velvet, stir, and then add 20% (owf) oxygen bleaching stabilizer ...

Embodiment 2

[0084] A method for decolorizing green velvet, comprising the following steps:

[0085] ①. Enzyme washing: put the green velvet into the loose hair dyeing vat at room temperature, add soft water, the bath ratio is 1:10~15, stir, and then add 1% (owf) non-ionic lotion and 0.2% (owf) mercerizing Protease soaking treatment, adjust the pH value to 9; increase the temperature by 2°C per minute to 40°C, keep warm for 25 minutes, empty, and wash with water;

[0086] ②. Pretreatment: Add soft water to the green velvet washed in step ①, stir, adjust the pH value to 4, add 4.5% (owf) of hydrosulfite, 0.5% (owf) complexing agent, 2% (owf) FeSO 4 ;Increase the temperature by 1°C per minute to 57°C, keep it warm for 40 minutes, empty it, and wash it twice with water;

[0087] ③. Oxygen bleaching: step ② add soft water to the washed green velvet, stir, add 10% (owf) oxygen bleaching stabilizer, 6% (owf) cashmere protective agent and 24% (owf) hydrogen peroxide for soaking and washing, adj...

Embodiment 3

[0090] A kind of decolouring method of green cashmere, comprises the following steps: wherein following concentration is relative green cashmere weight,

[0091] ①. Enzyme washing: Put the green velvet into the loose wool dyeing vat at room temperature, add soft water, the bath ratio is 1:10~15, stir, and then add 3% (owf) non-ionic lotion and 0.1% (owf) mercerizing Protease soaking treatment, adjust the pH value to 9; heat up to 45°C, keep warm for 20 minutes, empty, and wash with water;

[0092] ②. Pretreatment: add soft water to the green velvet washed in step ①, stir, adjust the pH value to 5, add 3% (owf) hydrosulfite, 0.7% (owf) complexing agent, 1.5% (owf) FeSO 4 ;Heat up to 56°C, keep warm for 50 minutes, empty, and wash twice with water;

[0093] ③. Oxygen bleaching: Step ② Add soft water to the washed green velvet, stir, add 15% (owf) oxygen bleaching stabilizer, 5% (owf) cashmere protective agent and 30% (owf) hydrogen peroxide for soaking and washing, adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com