High-speed wide 16-heald mesh-mark-free three-layer paper making mesh

A network mark and wide-width technology, which is applied in the field of high-speed and wide-width 16-shed papermaking three-layer wire without network marks, can solve the problems of short service life of the paper forming wire, insufficient wear resistance of the contact surface, and uneven formation of paper sheets. Achieve the effect of improving the retention rate of fibers and fillers, increasing the fiber support index, and firmly combining the upper and lower layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

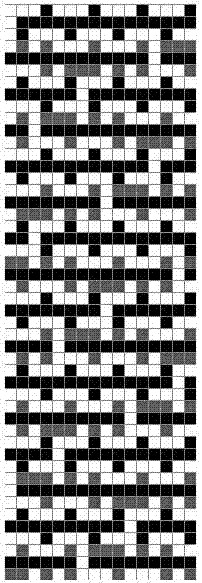

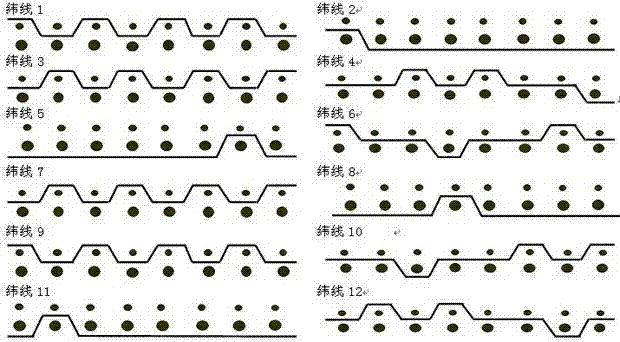

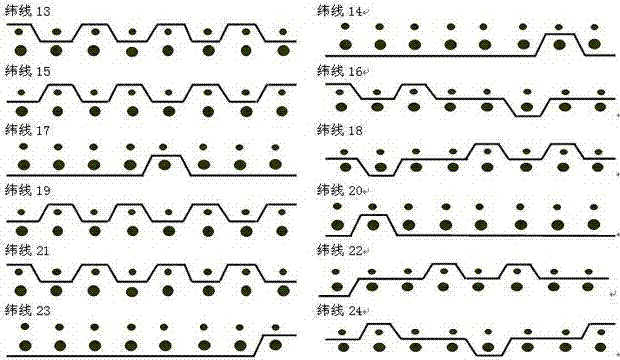

[0019] See Figure 1-5 This high -speed width 16 comprehensive net paper papermaking three -layer network is a rough papermaking net. It uses 16 comprehensive frames to connect polyester or nylon single -silk to the paper layer, middle connection layer and machine layer.The overall composite fabric, its minimum organizational unit is composed of 16 polyester wires and 48 polyester or nylon single as a weft line.The ratio ratio is 3: 2; the roots of the latitude line of the intermediate connection layer account for 2 / 6 of the total latitude line; in the paper layer, the passing of the polyester monocular is used, and the diameter of the passing line is 0.18.It is 0.18mm, and the 1 / 1 flat weaving method is used; the connection weft of the intermediate connection layer supports the support effect on the paper surface in the paper layer, and the intersection with the meridian of the machine layer will be sutured into a paper layer and a machine.The role of the layer is 0.18mm in diamet...

Embodiment 2

[0023] See Figure 1-5 This high -speed width 16 comprehensive net paper papermaking three -layer network is a rough papermaking net. It uses 16 comprehensive frames to connect polyester or nylon single -silk to the paper layer, middle connection layer and machine layer.The overall composite fabric, its minimum organizational unit is composed of 16 polyester wires and 48 polyester or nylon single as a weft line.The ratio ratio is 3: 2; the roots of the latitude line of the intermediate connection layer account for 2 / 6 of the total latitude line; in the paper layer, the passing of the polyester monocular, the diameter of the passing line is 0.24mm;The diameter is 0.24mm, and the 1 / 1 flat woven method is used; the connected weft line of the intermediate connection layer supports the support effect on the paper surface in the paper layer.The function of the machine layer is 0.24mm in diameter, and polyester monocular wire is used; in the machine layer, polyester monocular wire is used...

Embodiment 3

[0027] See Figure 1-5 This high -speed width 16 comprehensive net paper papermaking three -layer network is a rough papermaking net. It uses 16 comprehensive frames to connect polyester or nylon single -silk to the paper layer, middle connection layer and machine layer.The overall composite fabric, its minimum organizational unit is composed of 16 polyester wires and 48 polyester or nylon single as a weft line.The ratio ratio is 3: 2; the roots of the latitude line of the intermediate connection layer account for 2 / 6 of the total latitude line; in the paper layer, the passing of the polyester monocular, the diameter of the passing line is 0.21mm;The diameter is 0.21mm, and the 1 / 1 flat woven method is used; the connected weft line of the intermediate connection layer supports the support effect on the paper surface in the paper layer.The function of the machine layer is 0.21mm in diameter, and nylon monouks are used; in the machine layer, polyester monocular wire is used, the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com