turbine blade

A technology of turbine blades and blades, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve problems such as blocking the main flow channel, increasing the difficulty of heat transfer and cooling of turbine blade tips, and affecting the unsteadiness of the downstream flow field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, further detailed description will be given below in conjunction with specific embodiments, but it does not limit the present invention.

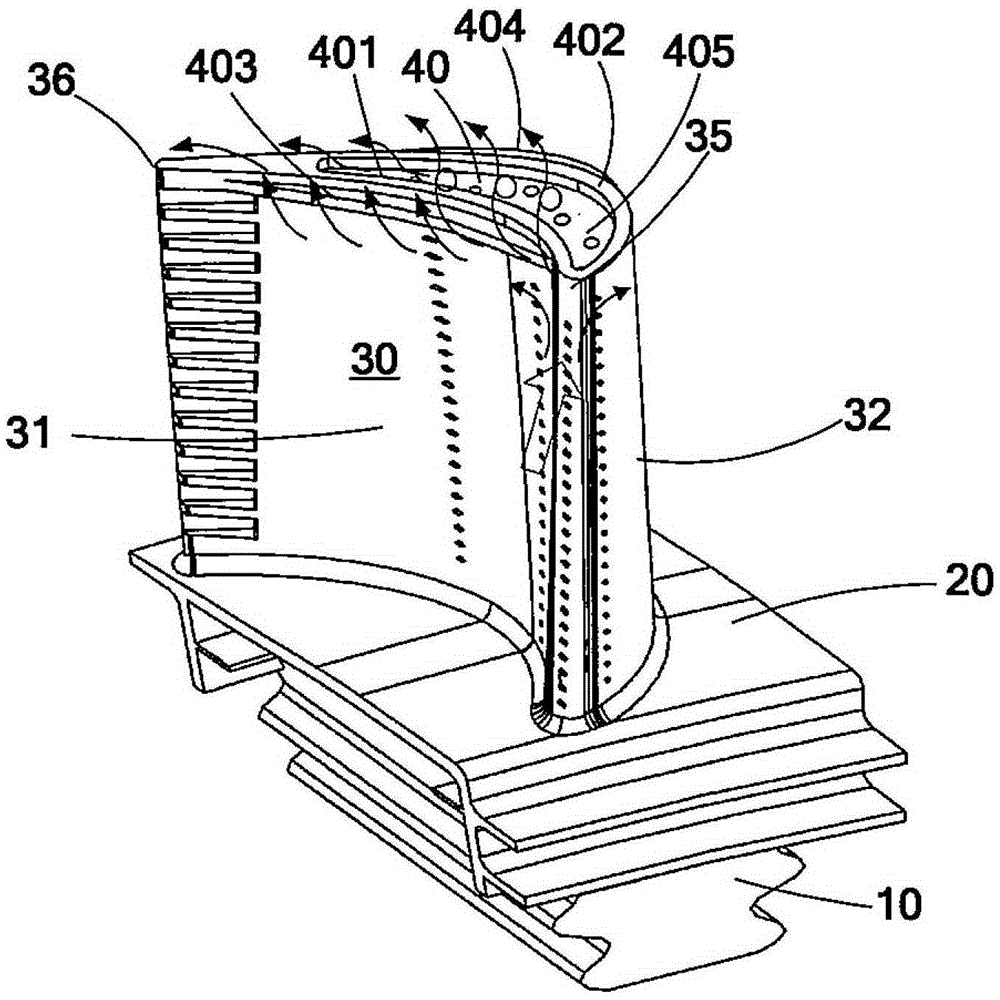

[0039] See first figure 1 , An exemplary turbine blade 30 for use in a gas turbine engine is shown. The blade is installed in the supporting rotor disk (not shown) through the edge plate 20 at the blade root and the supporting tenon 10. The supporting rotor disc supports a series of blades and the blades are circumferentially spaced apart from each other to form flow passages between the blades. During the operation of the turbine engine, the high temperature gas figure 1 As shown by the direction of the middle arrow, it flows to the blade leading edge 35 of the blade 30 and splits to flow to the pressure surface 31 and the suction surface 32. Since the relative pressure of the high-temperature fuel gas on the pressure surface 31 is higher than the pressure along the suction surface 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com