Detecting device and method for optical fiber oil-water interface

A detection device, optical fiber oil technology, applied in the direction of measuring device, lubrication indicator device, liquid level indicator, etc., can solve the problems of large deviation of detection results, complicated instruments, large longitudinal size of floating balls, etc., and achieve the goal of manufacturing and using Low cost, broad application prospects, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

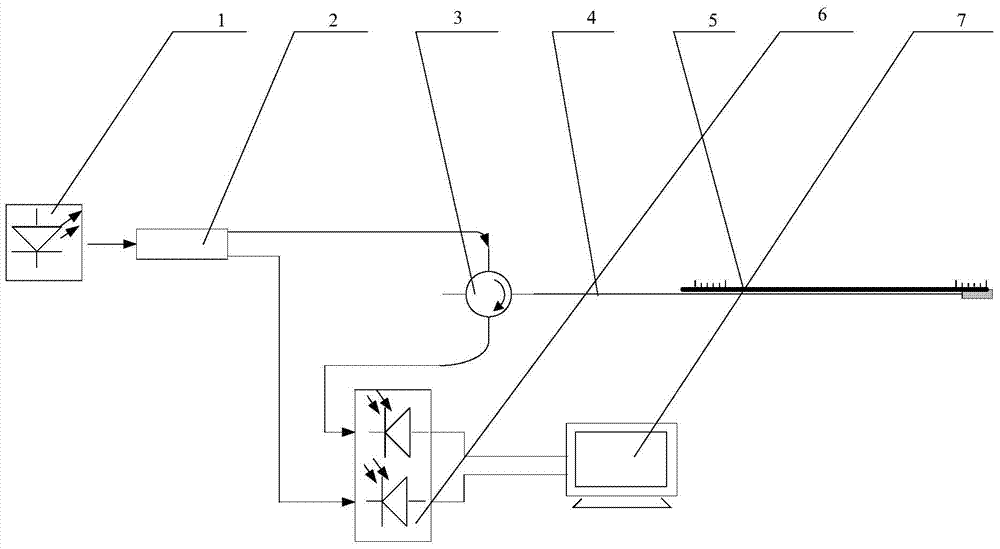

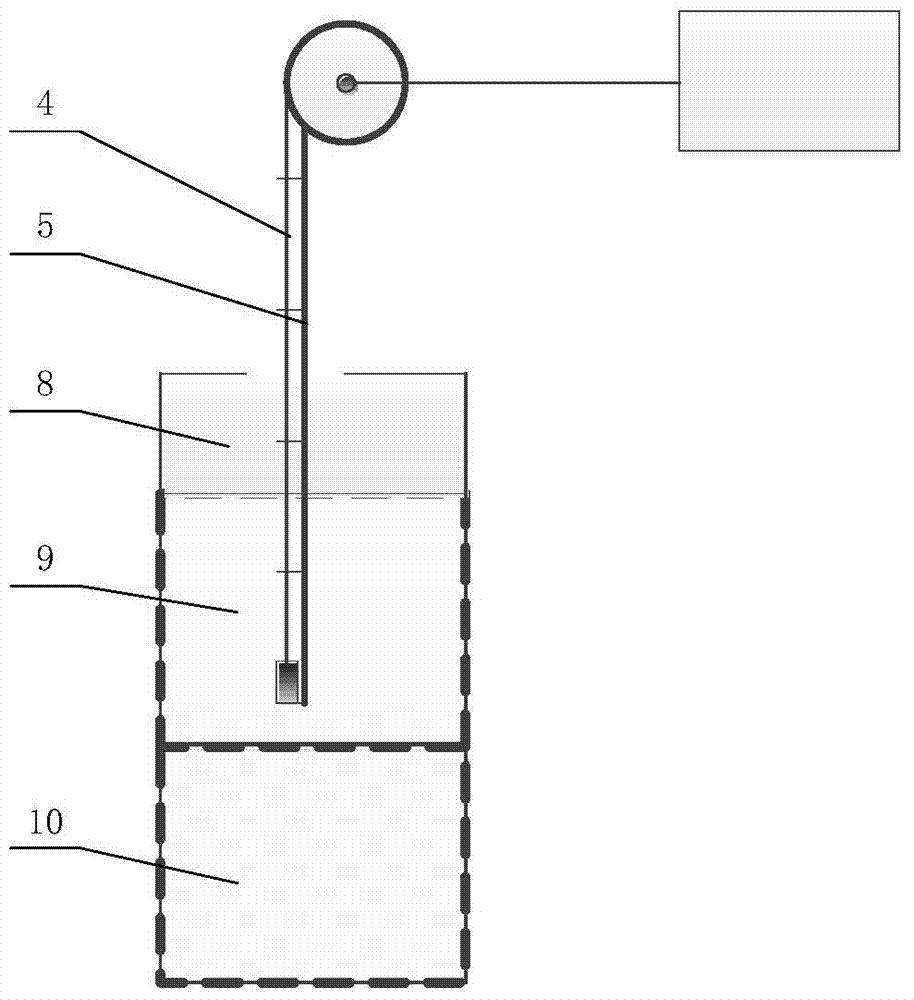

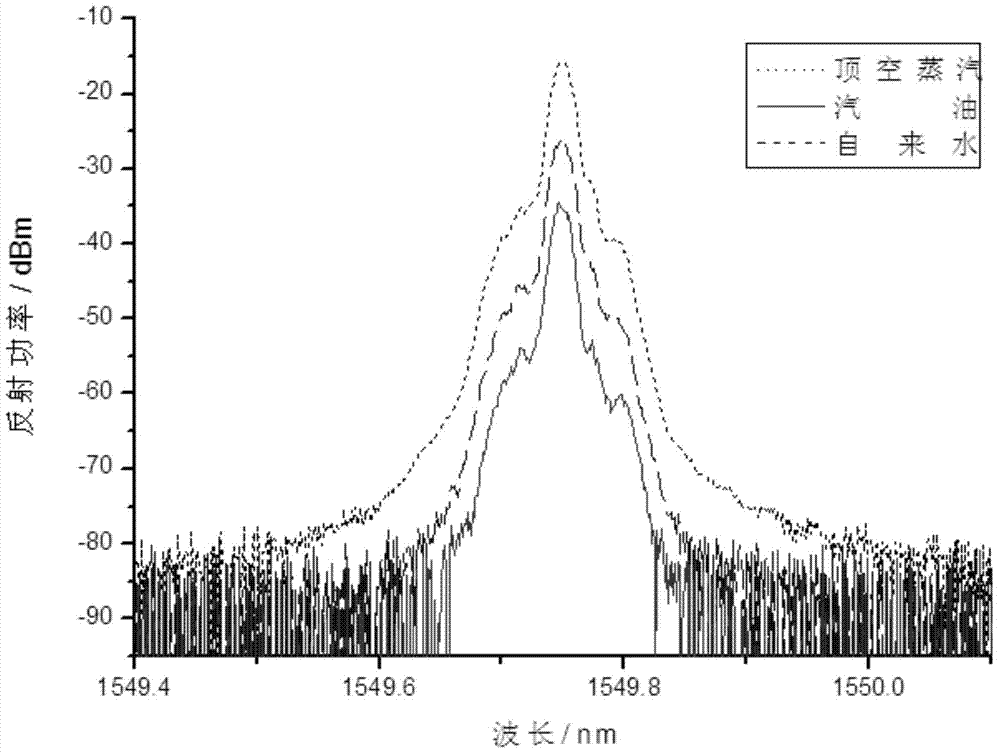

[0033] Such as figure 1 As shown, a detection device for an optical fiber oil-water interface of the present invention includes a narrow linewidth laser light source 1, an optical splitter 2, a circulator 3, an end-to-end pigtail 4, a length scale 5, a photodetector and signal processing with display module7. In this embodiment, the optical splitter 2 is a dual-path power divider, and the photodetector is a dual-optical-path photodetector 6 . A narrow linewidth laser source 1 is connected to an input end of an optical splitter 2 , and an output end of the optical splitter 2 is connected to a terminated pigtail 4 through a circulator 3 . The terminated pigtail 4 is preferably a G.652 optical fiber, and its free end is arranged side by side with the length scale 5 . For the convenience of reading, the end face of the free end of the pigtail 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com