Full bridge uncontrolled rectifier fault diagnosis method based on insulation monitoring

A technology of insulation monitoring and fault diagnosis, which is applied in the direction of instruments, measuring electronics, and measuring devices. It can solve problems such as system failure, high cost of rectifiers, and small faulty diodes, and achieve strong operability, increased complexity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

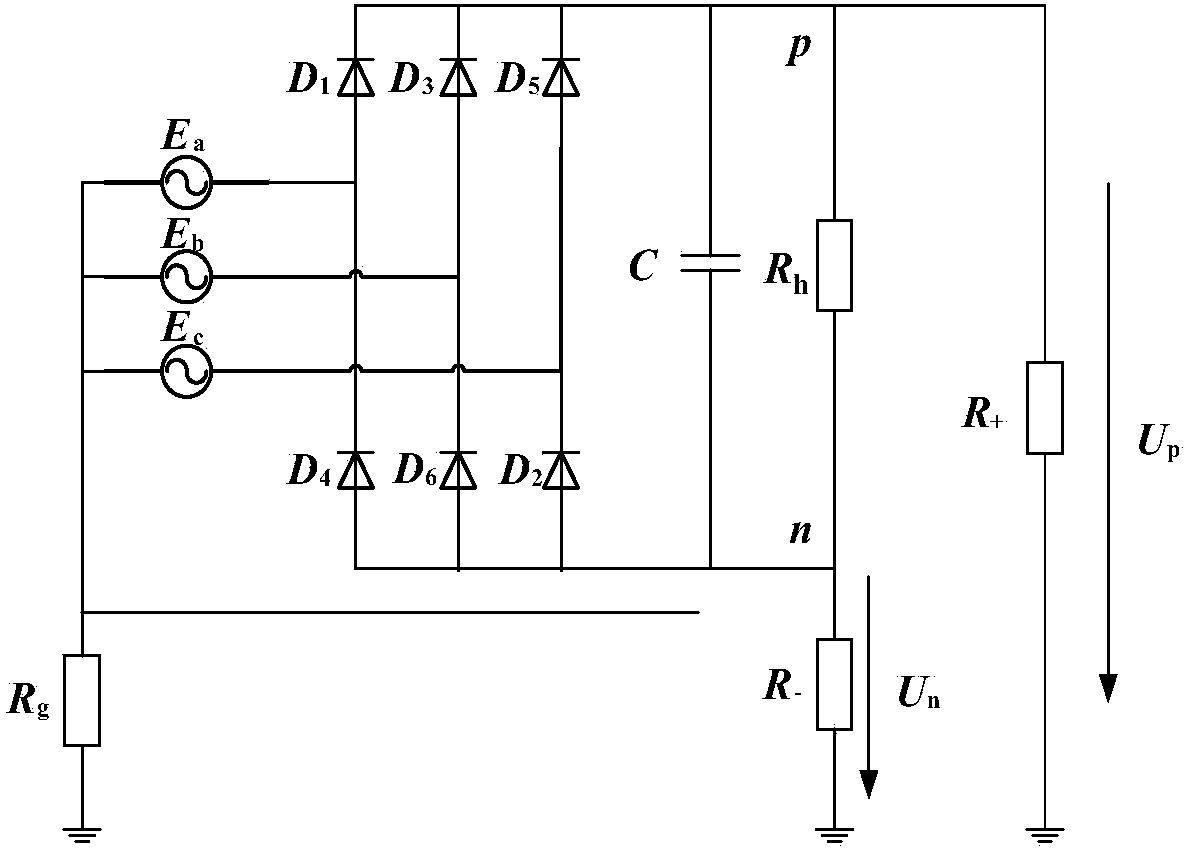

[0039] Such as figure 1 As shown, it is a circuit diagram of an IT system with a three-phase bridge uncontrolled rectifier. According to the switching function of the uncontrolled rectifier, the common cathode or common anode diodes are respectively turned on in one cycle, and the conduction of each diode occupies The duty ratio is one-third of a cycle. Using this feature, three diodes with a common cathode can be equivalent to a diode, and a diode with a common anode can also be equivalent to a diode. At the same time, the three-phase power supply can be The upper and lower bridge arms are equivalent, respectively E p ,E n , and finally the R h , R + , R - The three delta-connected resistors, through △-Y transformation, become by R p , R n , R l composed of Y-connected resistors.

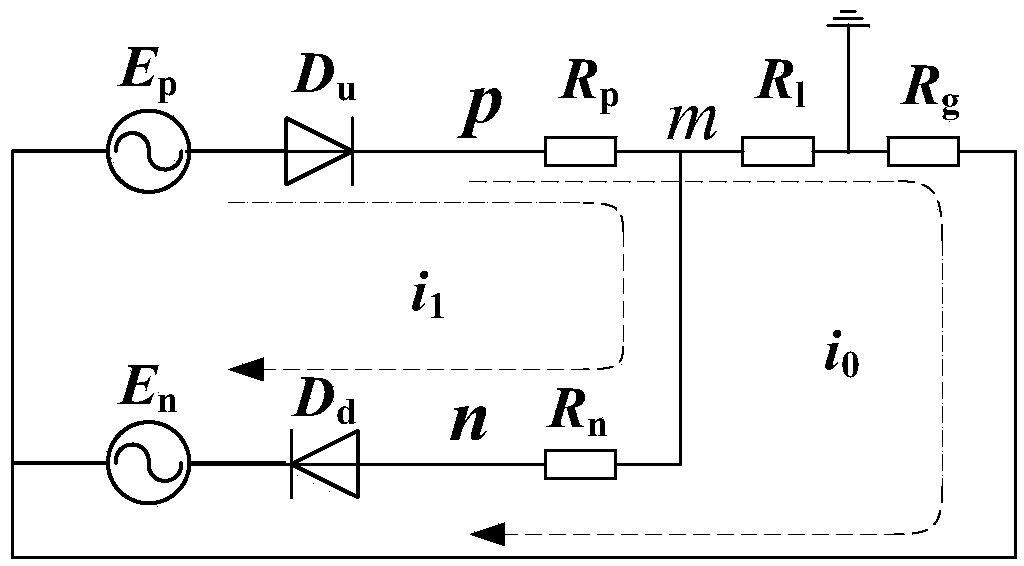

[0040] Such as figure 2 Shown, D u is the equivalent common cathode diode, D d is an equivalent common anode diode, and the equivalent resistance and equivalent power supply in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com