Parallel bundled overhead conductor

A technology for overhead wires and wires, applied to power cables, electrical components, circuits, etc., can solve the problems of large line voltage loss, low safety factor, time-consuming and laborious, etc., to reduce the cost of wires, improve the safety factor of operation, and identify the phase sequence clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

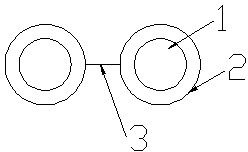

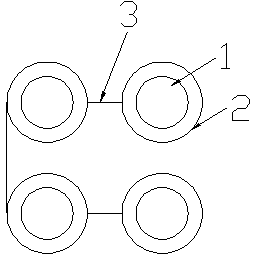

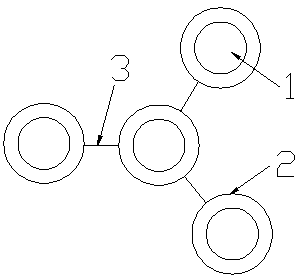

[0013] Such as figure 1 Shown: a parallel bundled overhead wire, including two wires 1 with insulation 2, the wires are aluminum alloy wires, all the wires are arranged side by side, and the wires are connected by connecting ribs 3; as figure 2 with image 3 As shown, the number of the wires is four, and the four wires are arranged in a rectangular shape or a star shape; the insulation is polyvinyl chloride insulation, cross-linked polyethylene insulation or weather-resistant polyethylene insulation.

[0014] In the three-phase four-wire power supply system, the aluminum alloy parallel bundled conductors can minimize the unbalance of the three-phase load of the distribution transformer, reduce the neutral wire current, and thereby reduce the resistance loss. Due to the compact symmetrical split structure, the inductance of the wire is reduced, the dielectric constant between the wires is increased, the capacitance is increased, the circuit reactance is greatly reduced, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com