Rotating electrical machine and housing for rotating electrical machine

A technology for rotating electrical machines and housings, which is applied in the field of rotating electrical machines and housings of rotating electrical machines, and can solve problems such as the inability to cool the electric machine and the inability to guide air to the heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

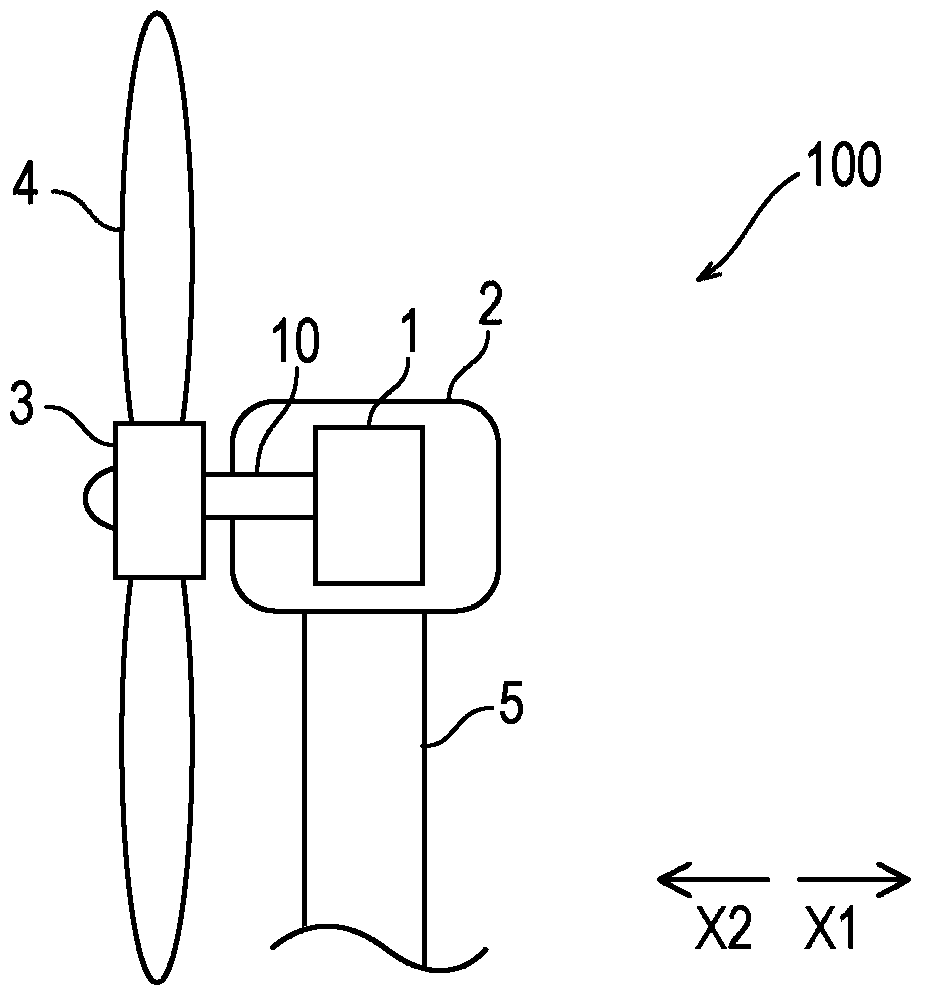

[0023] First, refer to figure 1 The configuration of the wind power generation system 100 will be described.

[0024] Such as figure 1 As shown, the wind power generation system 100 includes a generator 1 , a nacelle 2 for accommodating the generator 1 , a rotor hub 3 , blades 4 , and a tower (support column) 5 . The generator 1 is accommodated in the nacelle 2 . In addition, the rotor hub 3 is attached to a rotating shaft 10 of the generator 1 which will be described later. In addition, a plurality of blades 4 are mounted on the rotor hub 3 . In addition, the nacelle 2 is mounted on a tower 5 .

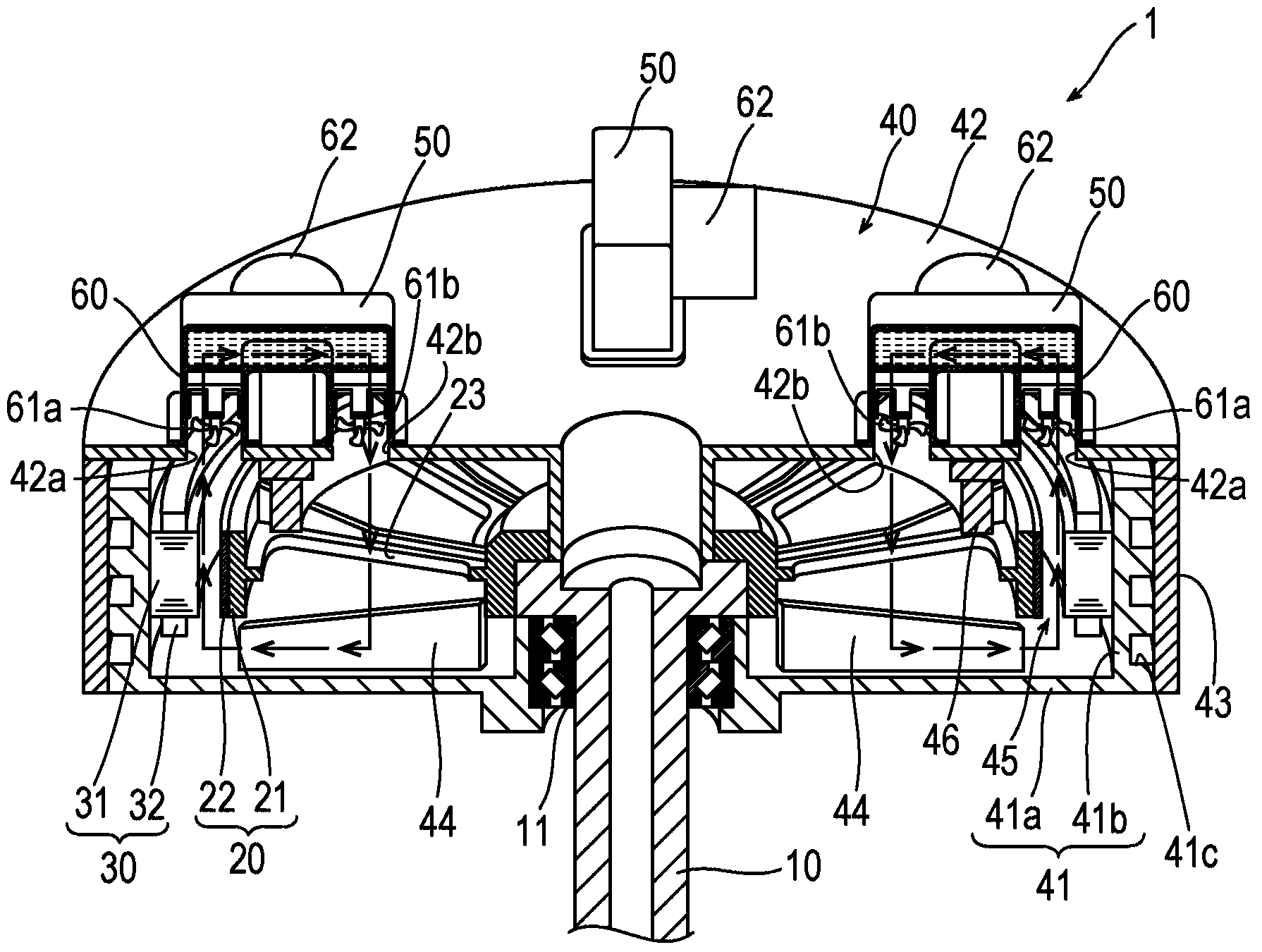

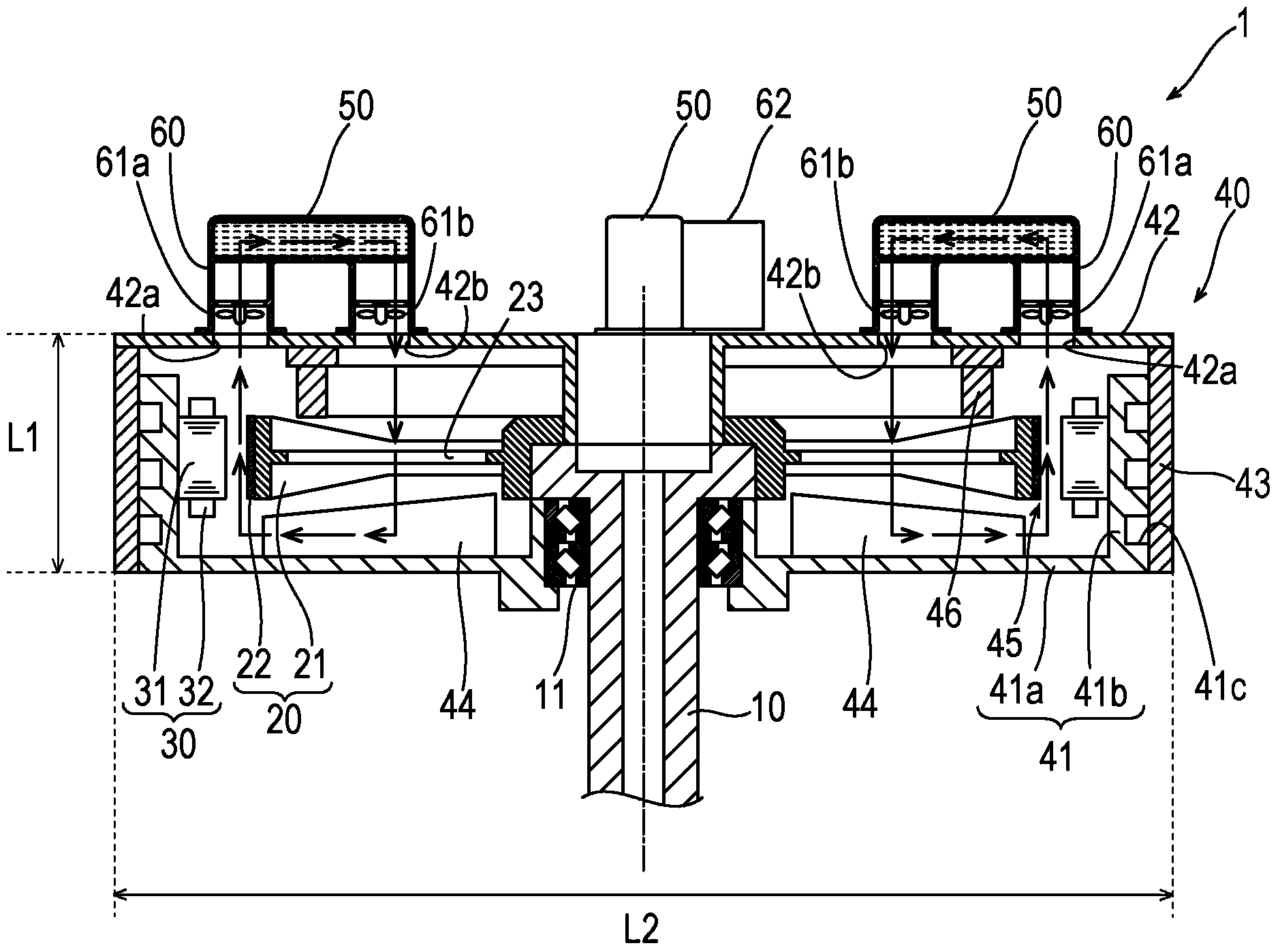

[0025] Below, refer to Figure 2 to Figure 7 The configuration of the generator 1 according to the first embodiment will be described. In addition, the generator 1 is an example of a "rotating electric machine".

[0026] Such as figure 2 and image 3 As shown, the generator 1 includes a rotating shaft 10 , a rotor 20 , a stator 30 , a case 40 for accommodating the rotor 20 ...

no. 2 approach

[0056] Refer below Figure 8 ~ Figure 11 The configuration of the generator 101 of the second embodiment will be described. In addition, in the second embodiment, the generator 101 is a generator for wind power generation. In addition, the generator 101 is an example of a "rotating electric machine".

[0057] Such as Figure 8 As shown, the generator 101 includes a rotating shaft 110 , a rotor 120 , a stator 130 , a housing 140 for accommodating the rotor 120 and the stator 130 , and a heat exchanger 150 . The rotating shaft 110 is connected to the rotor 120 . In addition, a bearing 111 is provided between the rotating shaft 110 and the housing 140 . In addition, the housing 140 includes brackets 141 and 142 and a sheath 143 .

[0058] Such as Figure 8 As shown, the stator 130 is arranged to face the outer peripheral portion of the rotor 120 . Additionally, if Figure 8 , Figure 9 and Figure 10 As shown, the stator 130 includes: a stator core 131; and a slot 132 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com