Load driving device and driving method thereof

A load driving and driving signal technology, which is applied in the direction of lighting devices, lamp circuit layout, light source, etc., can solve the problems of increasing printed circuit boards, reducing time and energy, increasing capacitance, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

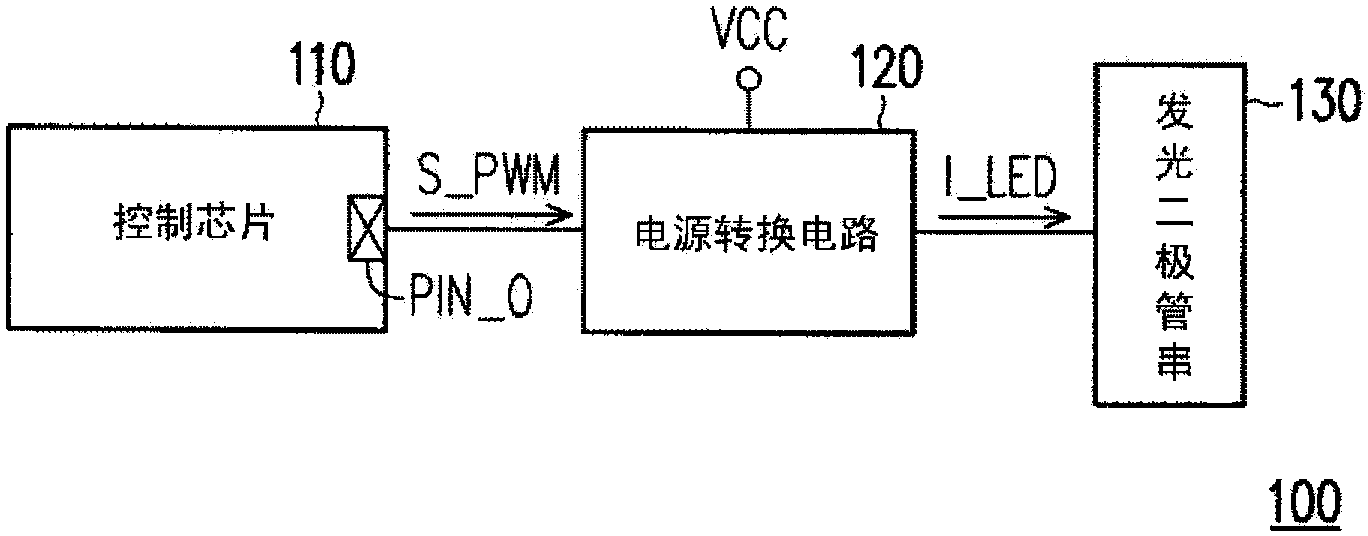

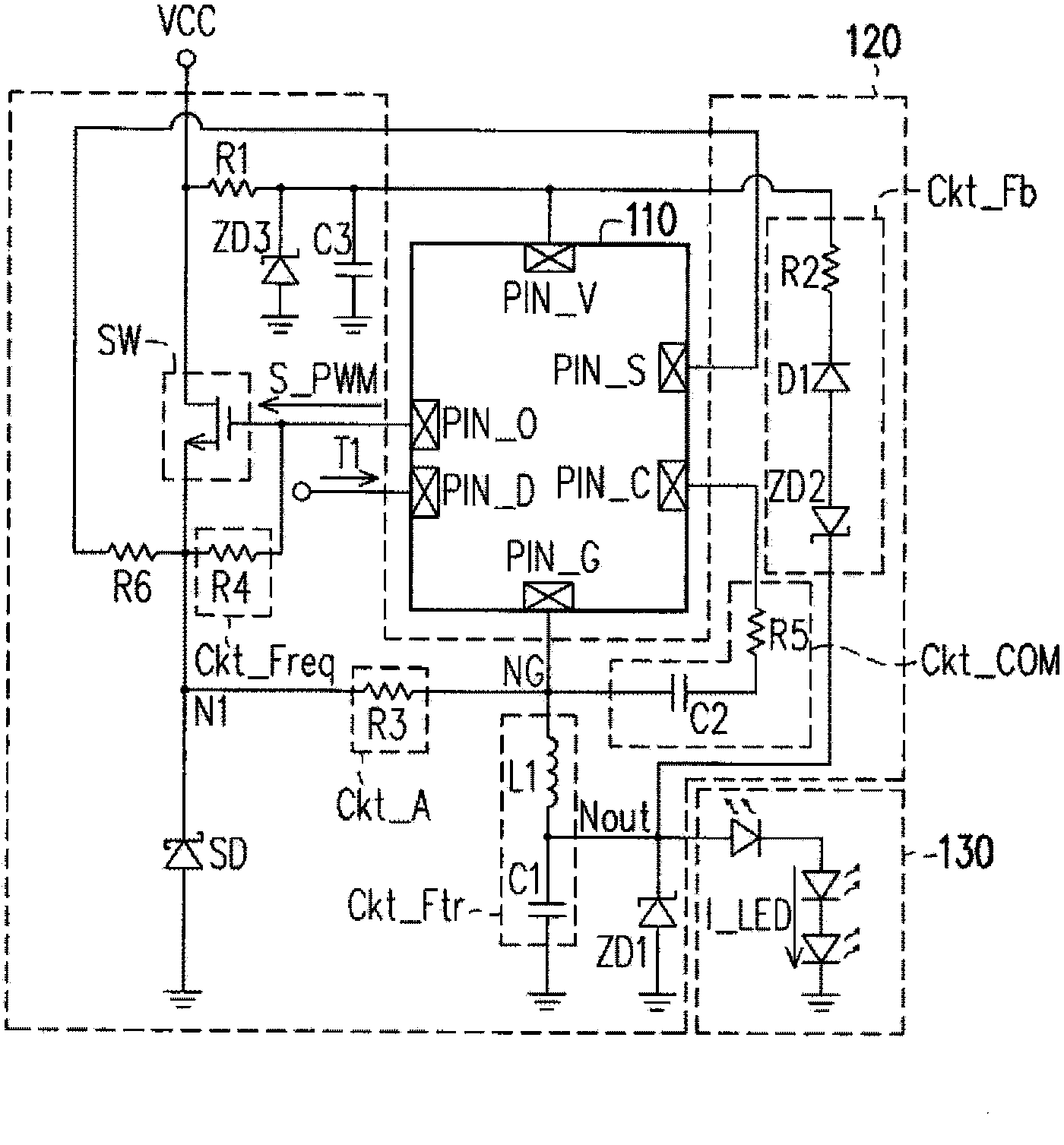

[0023] figure 1 It is a schematic block diagram of a load driving device according to an embodiment of the present invention. In this embodiment, the load driving device 100 is at least suitable for driving the LED string 130 . Please refer to figure 1 , the load driving device 100 includes a power conversion circuit 120 and a control chip 110 . The power conversion circuit 120 is coupled to the LED string 130 . The control chip 110 is coupled to the power conversion circuit 110 for controlling the operation of the power conversion circuit 120 . exist figure 1 Under the structure of the power conversion circuit 120 shown, the power conversion circuit 120 switches to enable or disable the power conversion in response to the pulse width modulation (Pulse Width Modulation, PWM) signal S_PWM provided by the output pin PIN_O of the control chip 110. The circuit 120 is used for the DC input voltage VCC to drive the LED string 130 .

[0024] In order to further describe the emb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap