Sputtering systems for liquid target materials

A sputtering system and liquid target technology, applied in sputtering coating, semiconductor devices, metal material coating technology, etc., can solve the problems of no production environment, difficult and expensive alloy targets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

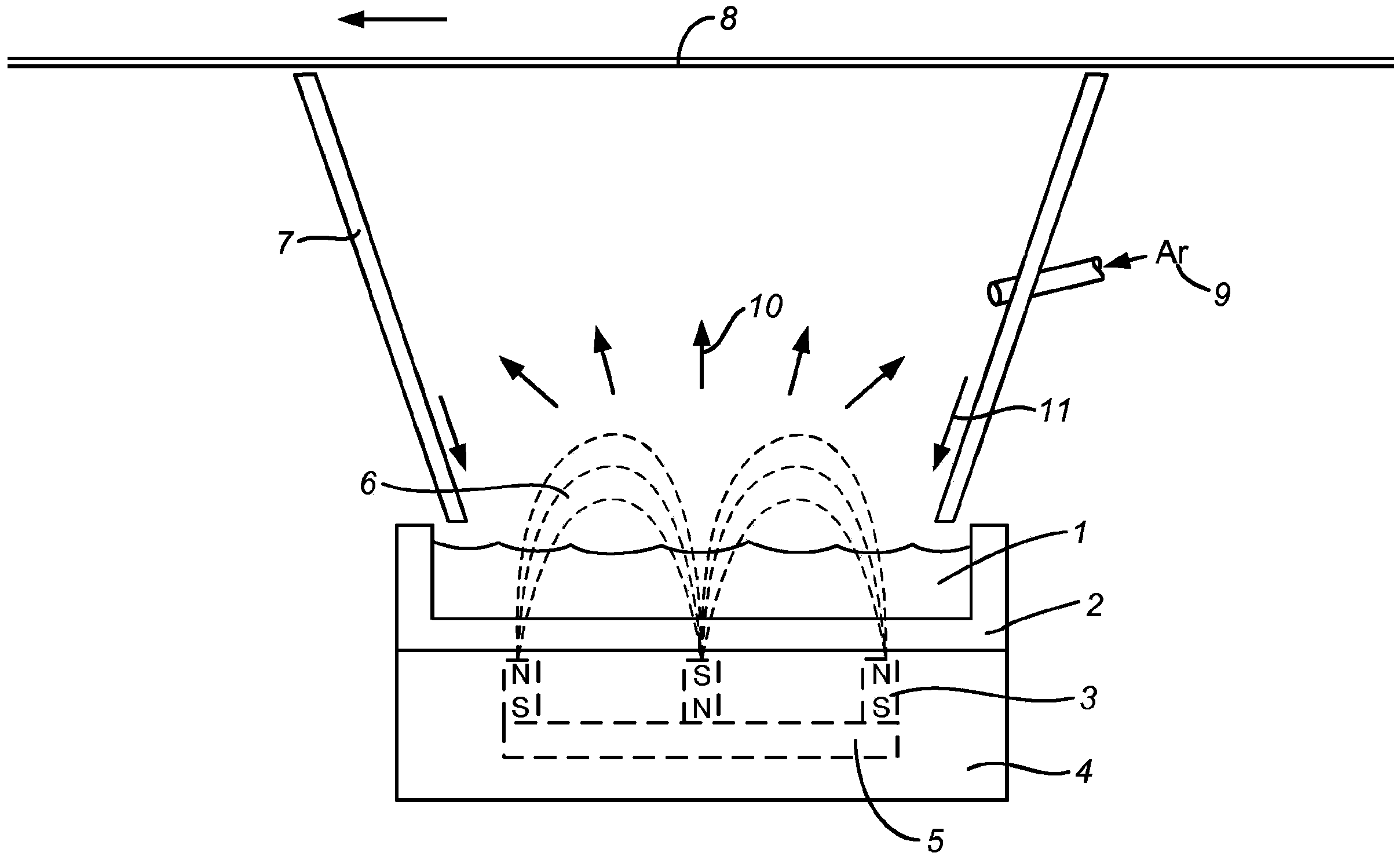

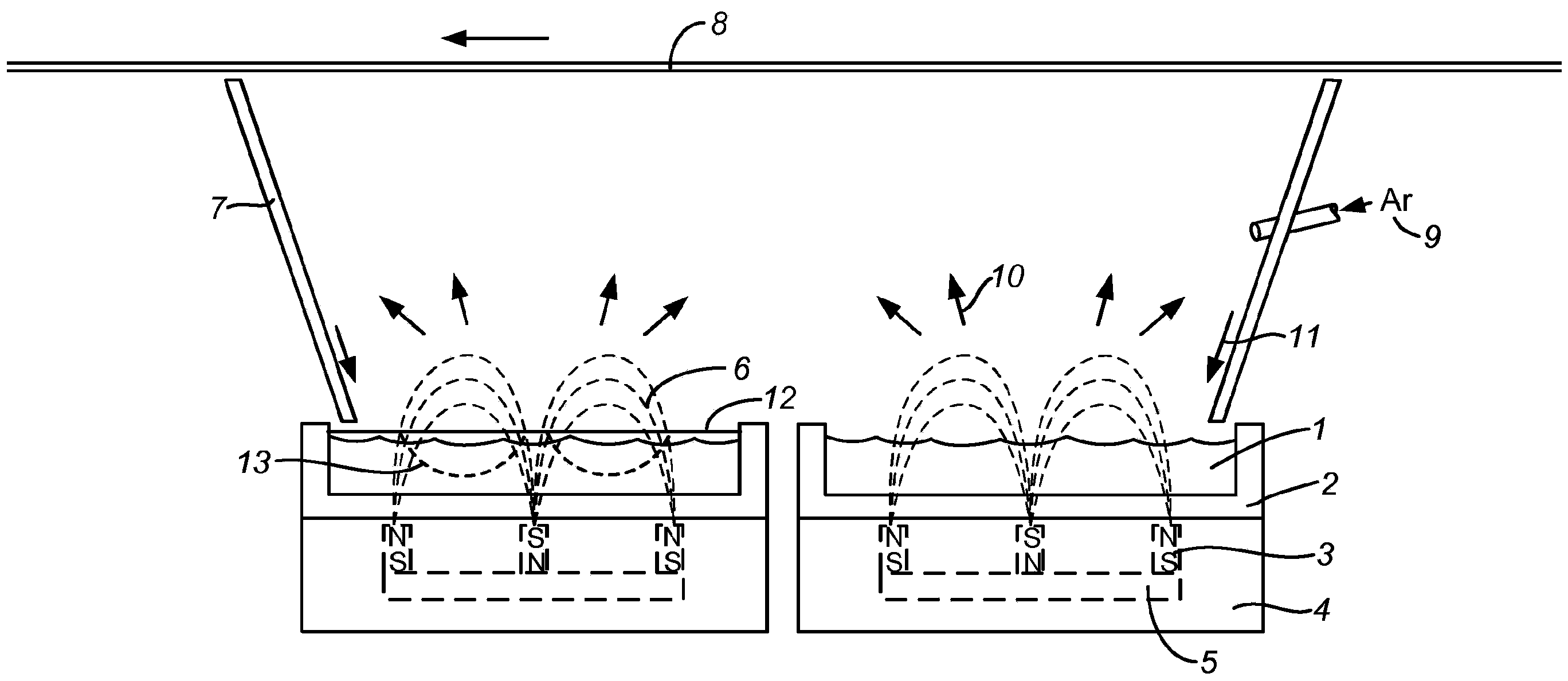

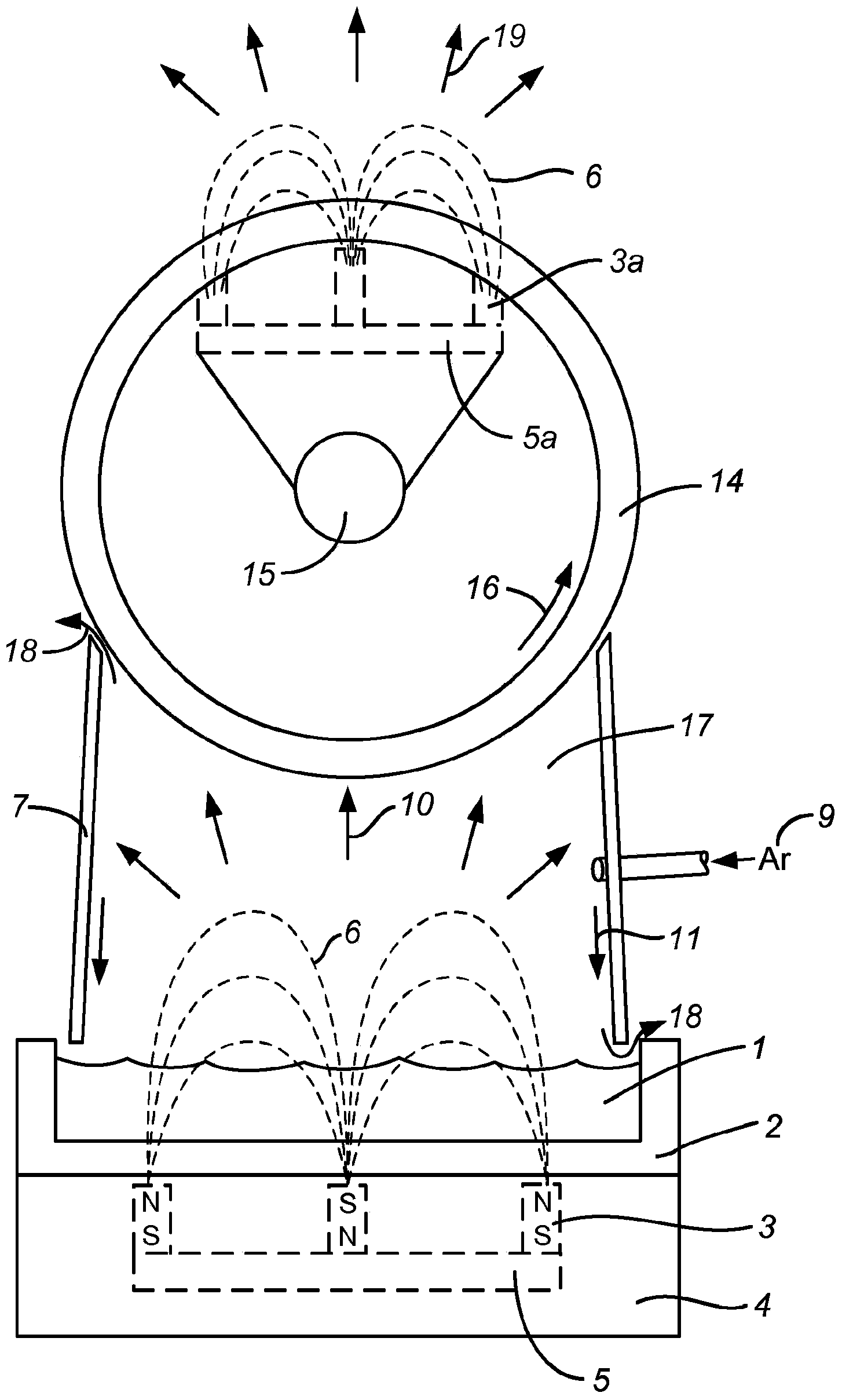

[0053] Magnetron components (such as figure 2 or image 3 shown) contains a horizontal magnetron with a gallium-containing liquid target and a rotatable magnetron with an indium-containing solid target. The flow of gallium and indium from the rotatable magnetron by applying DC power to the rotatable magnetron and horizontal magnetron while the rotatable magnetron is rotating at a rate of about 15 rpm And produced. A DC power of about 1 kW / ft target was applied to the horizontal magnetron; a DC power of about 3 kW / ft target was applied to the rotatable magnetron. chamber between the magnetrons (e.g. image 3 Chamber 17) operates at an argon pressure of about 5 millitorr (mTorr), the chamber with the magnetron assembly (e.g. image 3 The chamber 22) is operated at an argon pressure of about 3 mTorr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com