Liquid-metal printed circuit board and preparation method thereof

A printed circuit board and liquid metal technology, applied in printed circuit components, circuit substrate materials, metal pattern materials, etc., to ease constraints, facilitate rapid system construction and testing, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

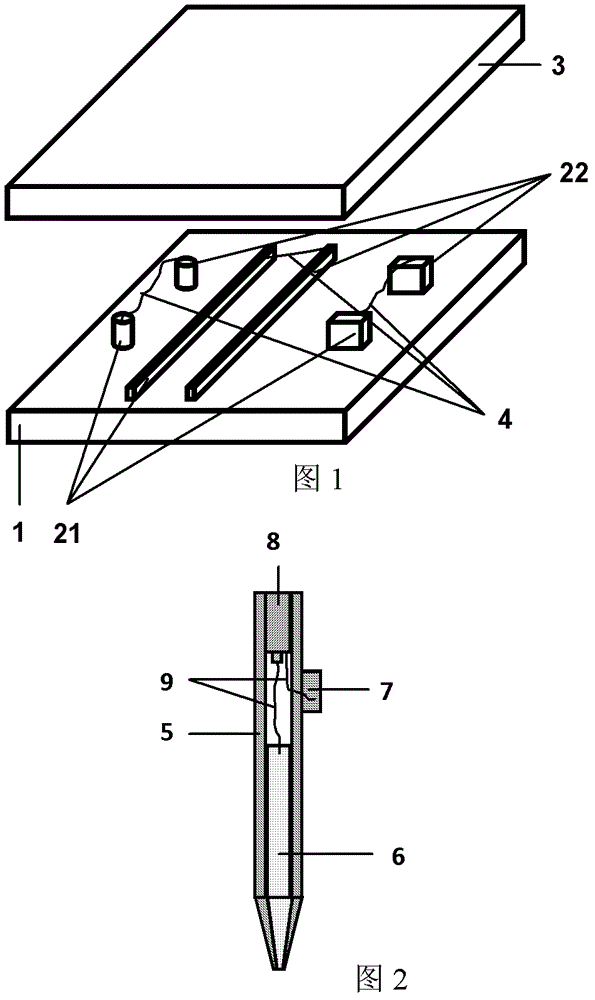

[0057] figure 1 It is a schematic structural diagram of a printed circuit board according to Embodiment 1 of the present invention.

[0058] Choose 200mm×200mm glass fiber reinforced epoxy resin substrate 1, and polish it with 600 mesh water sandpaper;

[0059] Operated by hand or machine control at room temperature figure 2 As shown in the pen-type device 5, turn on the switch 7 to energize and heat the liquid metal ink 6, so as to ensure that the liquid metal ink 6 is in a liquid state with better flow, and the first liquid metal ink (liquid gallium) is formed in the form of points, lines or surfaces. Formally coated on the upper surface of the substrate 1 to form a first room temperature liquid metal electrode 21 in the shape of a point, a line or a plane;

[0060] Likewise, at room temperature by hand or machine control figure 2 As shown in the pen-type device 5, turn on the switch 7 to energize and heat the liquid metal ink 6, so as to ensure that the liquid metal in...

Embodiment 2

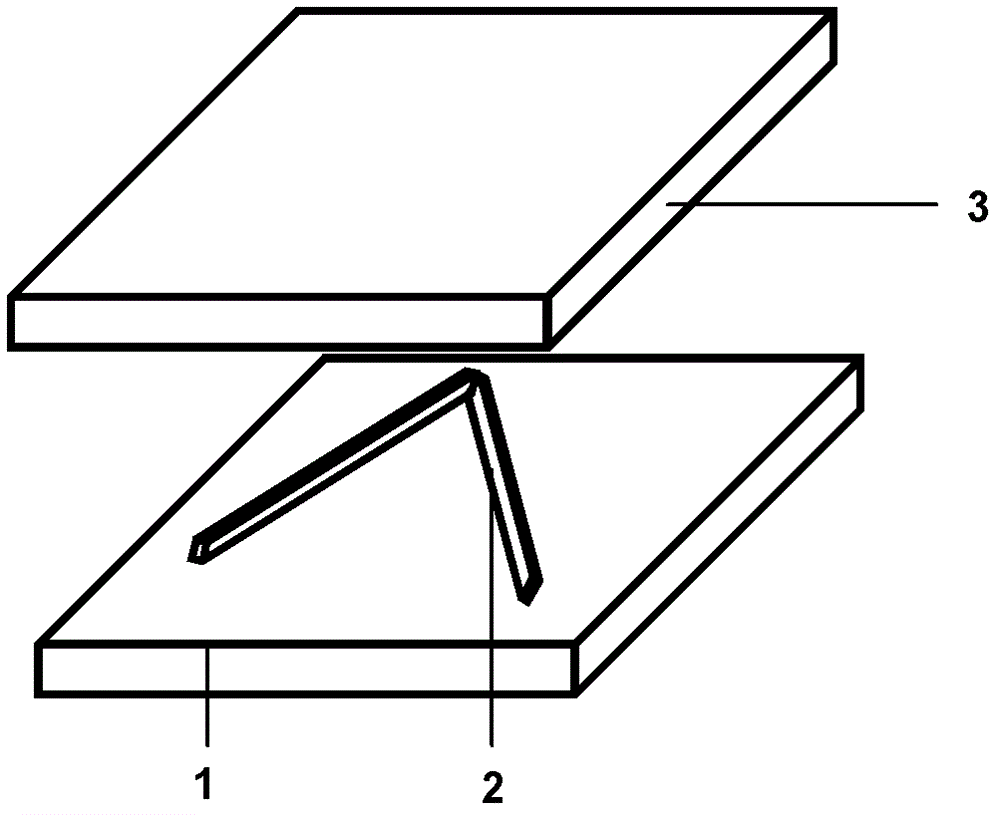

[0063] image 3 It is a schematic structural diagram of a printed circuit board according to Embodiment 2 of the present invention. Different from Embodiment 1, the two liquid metal electrodes do not need to be connected by wires or electronic components 4, but directly connect two liquid metals with different components. In this way, circuits made of different liquid metal inks are connected. line to achieve a specific function.

[0064] Choose 200mm×200mm glass fiber reinforced epoxy resin substrate 1, and polish it with 600 mesh water sandpaper;

[0065] Operated by hand or machine control at room temperature figure 2 As shown in the pen-type device 5, the first liquid metal ink (liquid gallium indium tin alloy) is coated on the upper surface of the substrate 1 with a line, and at the same time, a different liquid alloy material (liquid gallium indium tin alloy) is used on the substrate 1 Another line is coated on the upper surface, and one end of the two lines intersec...

Embodiment 3

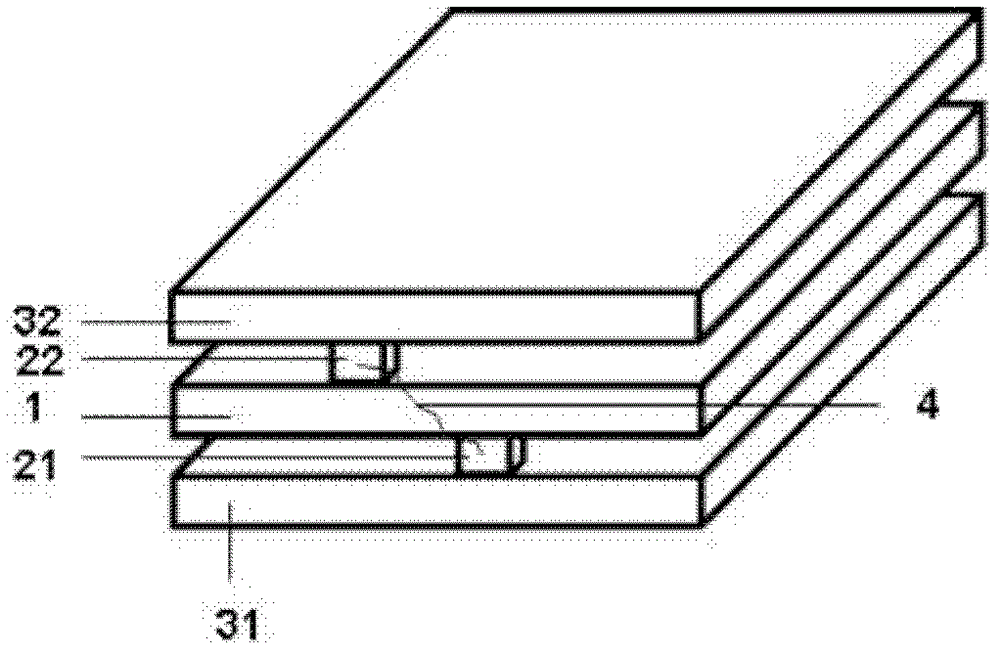

[0068] Figure 4 It is a schematic structural diagram of a printed circuit board according to Embodiment 3 of the present invention. The difference from Example 1 and Example 2 is that the liquid metal ink can be applied to different surfaces of the substrate and combined with each other, instead of simply being applied on the same surface, so that more complex circuit connections can be realized, thereby completing More specific functions.

[0069] Select 200mm×200mm cotton base 1;

[0070] Operated by hand or machine control at room temperature figure 2As shown in the pen-shaped device 5, the first liquid metal ink (liquid gallium mixed with 0.01wt% to 80wt% nano-semiconductor material particles) is coated on the lower surface of the substrate 1 in the form of dots, lines or planes to form dots. , the first room temperature liquid metal electrode 21 in the shape of a line or a plane; the semiconductor material particles are germanium sulfide particles, germanium selenide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com