Liquid injection type cage ball aortic valve support system

A technology of aortic valve and stent system, which is applied in the field of interventional therapy equipment and medical equipment, and can solve the central regurgitation service life of the three-leaflet bioprosthesis, obstruction of coronary blood flow, valve stents and periprosthesis of the three-leaflet bioprosthesis To avoid problems such as lateral leakage, to avoid obstructing coronary blood flow, eliminate central regurgitation, and reduce circumferential leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments.

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

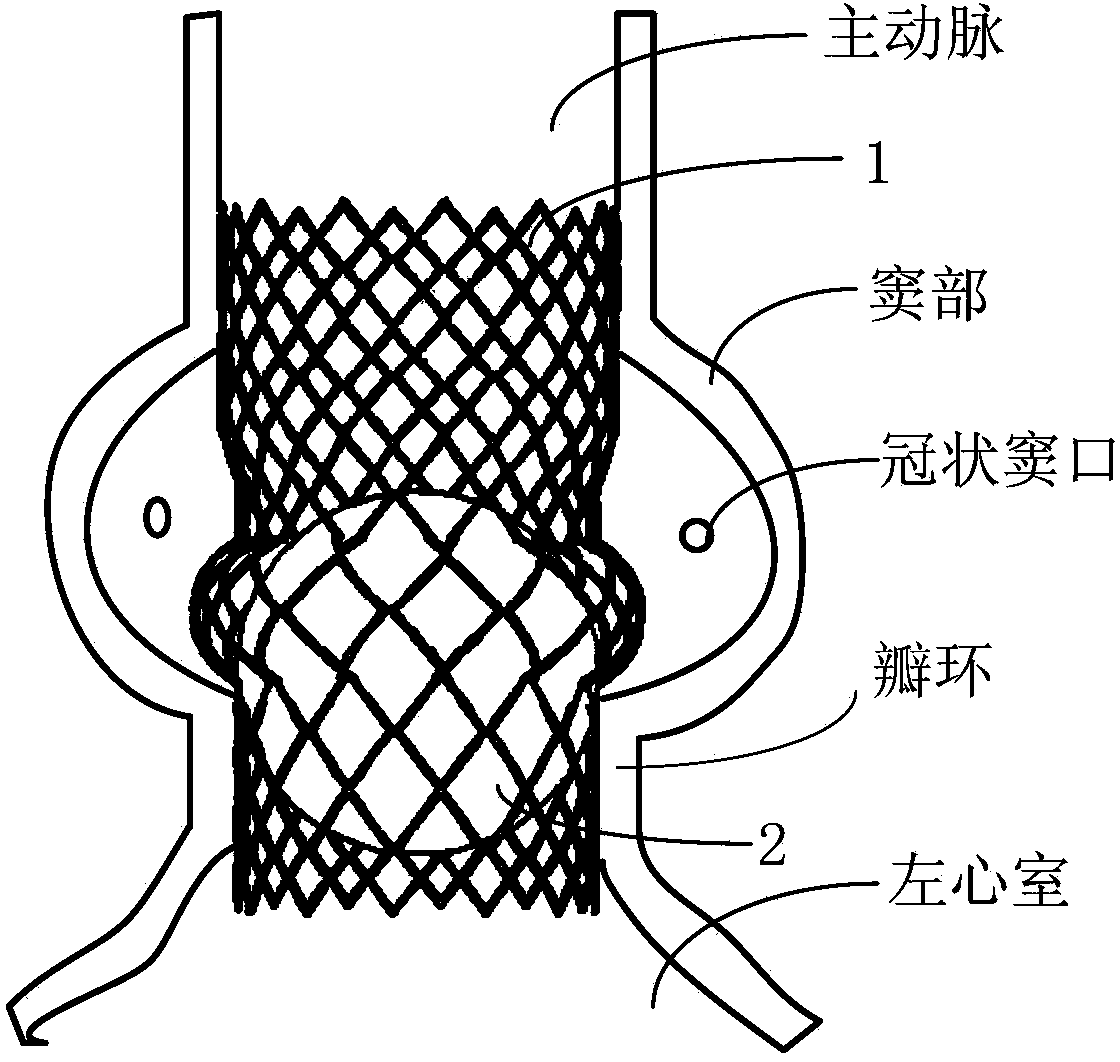

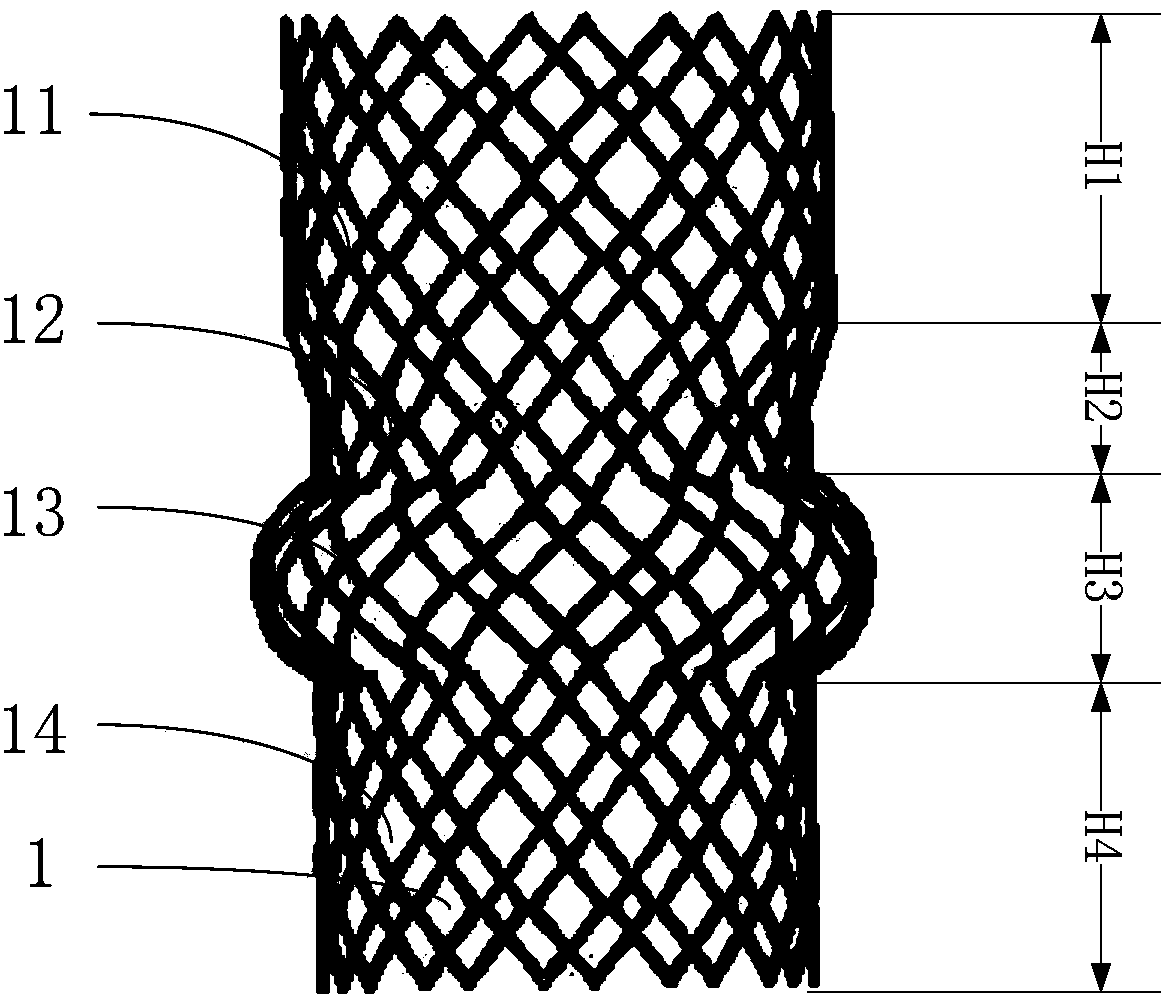

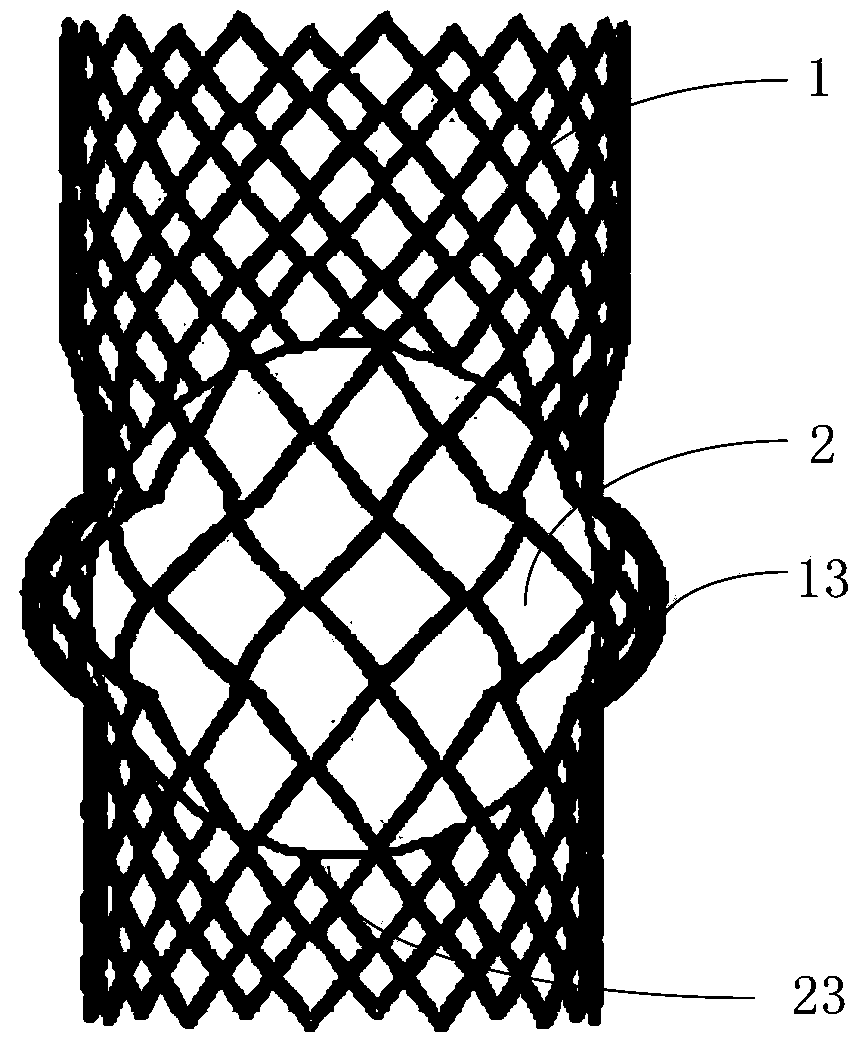

[0020] Reference figure 1 , The working position of the liquid-filled cage ball aortic valve stent system in the heart. In this embodiment, the system includes a stent body 1 and a liquid-filled ball 2. The stent body 1 is anchored to the aorta and valve annulus after being delivered to the patient’s aortic valve via a catheter through a human artery or through the apex. The filling ball 2 is installed in the stent body 1. The pressure difference between the left ventricle and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com