Collector and collector set for packed tower

A technology for packed towers and liquid collectors, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of less collected liquid, increased mechanical processing difficulty, and uneven gas distribution. , to achieve the effect of smooth gas rise, increased manufacturing difficulty, and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

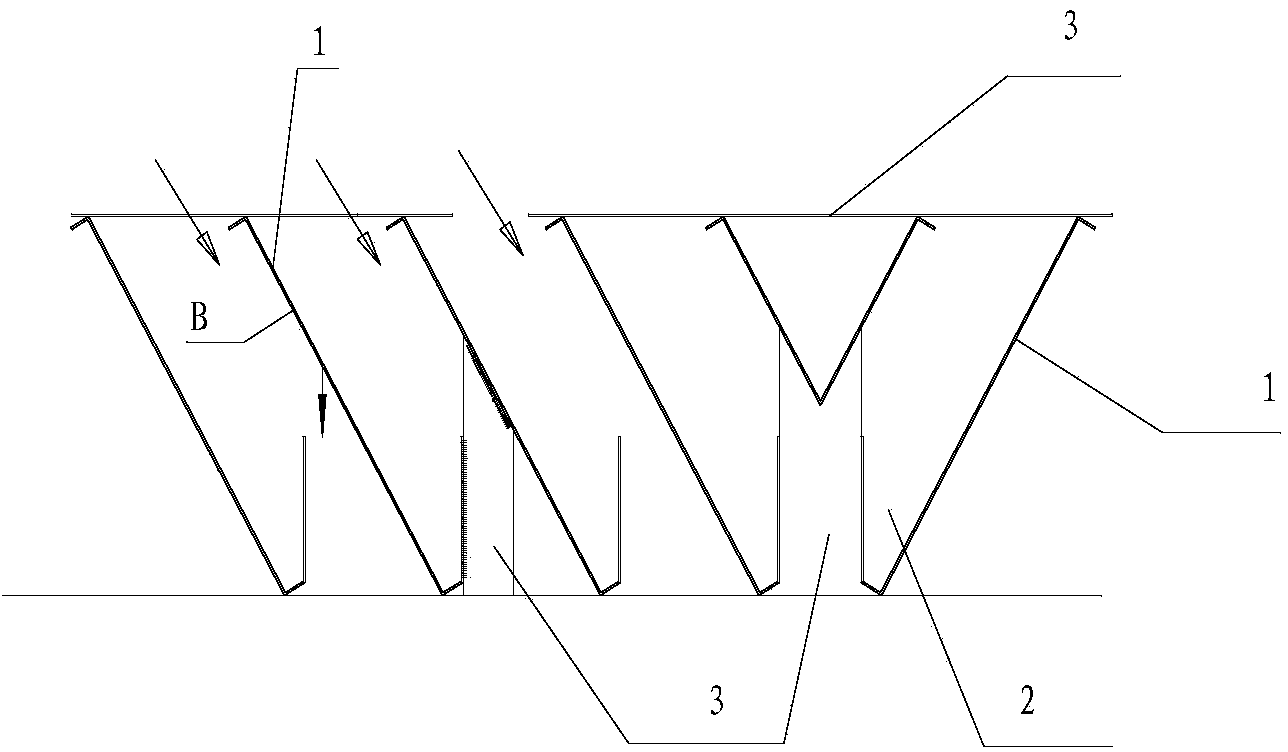

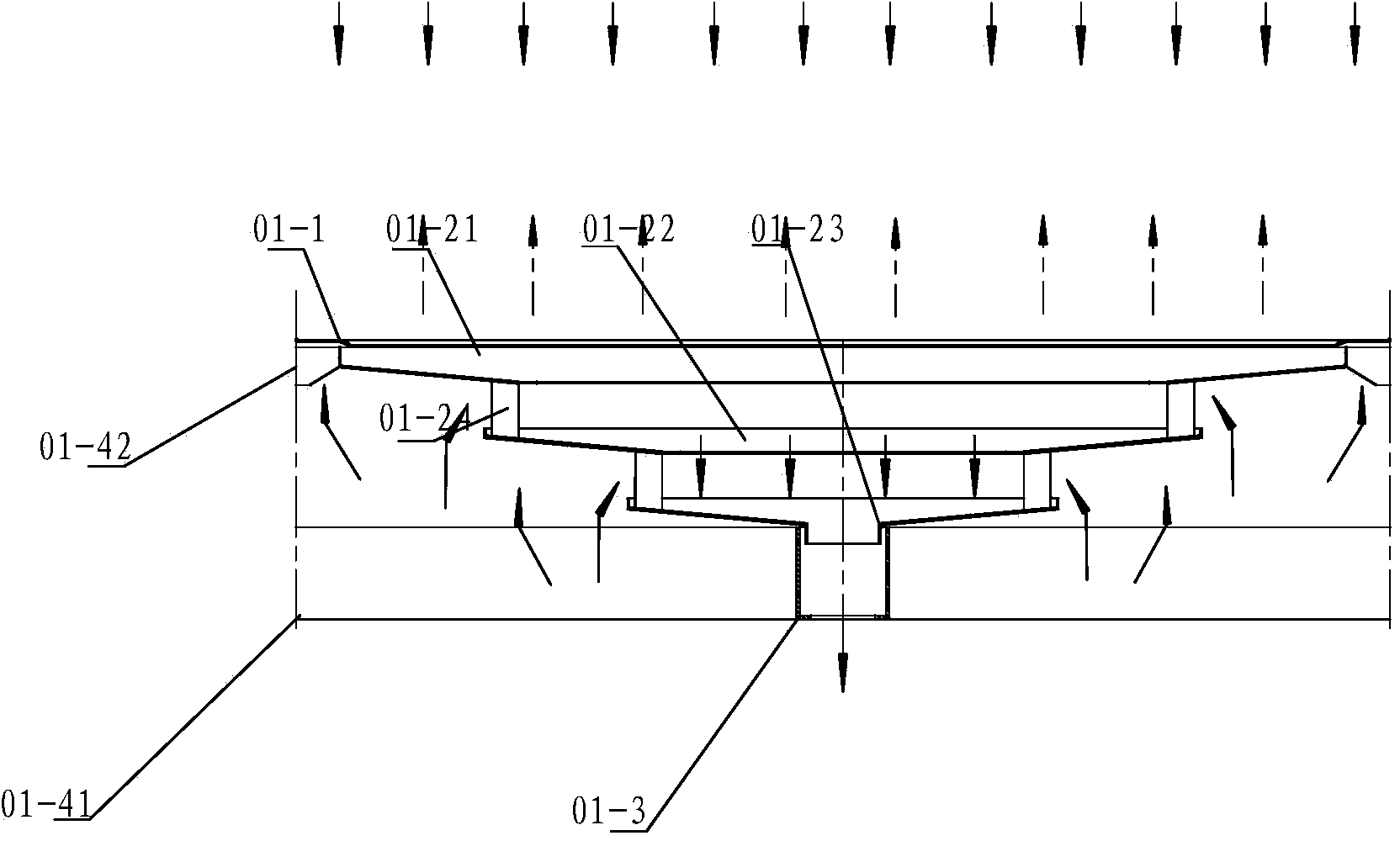

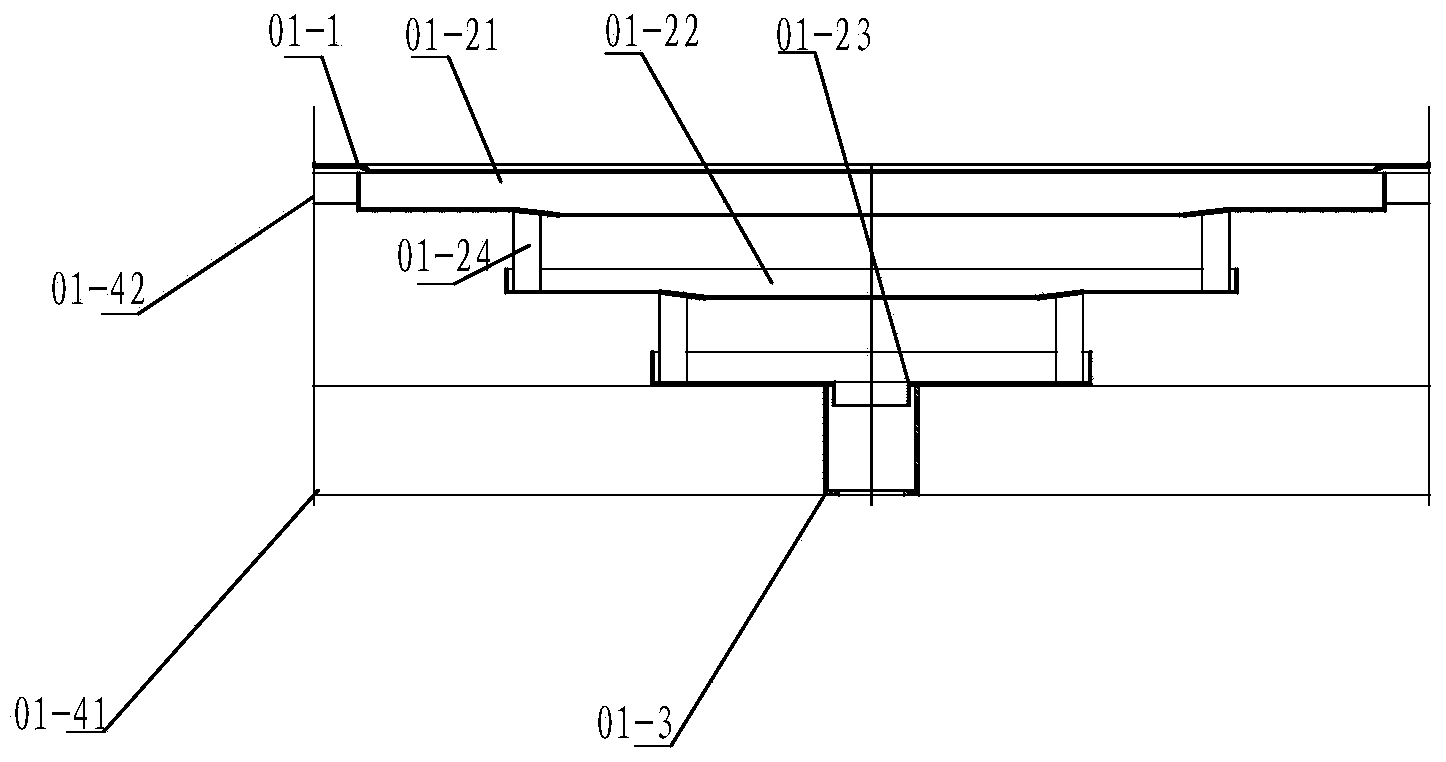

[0024] Such as figure 2 and image 3 As shown, the liquid collector used for packed towers of the present invention includes a layered structure of inverted shroud rings, and each layer of inverted shroud rings is a hollow inverted truncated cone. The outer edge decreases layer by layer from top to bottom, and the projections of the above-mentioned inverted shroud ring groups from top to bottom are that the adjacent layers partially overlap each other, and the adjacent two layers of inverted shroud ring groups pass through the connecting plate 01-24 The connection is fixed, and an annular shield 01-1 is set at intervals above the annular top of the uppermost inverted shield ring. When installing, the annular shield is welded to the tower wall, and the annular shield 01-1 is connected to the uppermost inverted shield. The annular tops of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com