High-precision numerical control tapping machine

A tapping machine, high-precision technology, applied in the field of tapping machines, can solve the problems of time-consuming and laborious, the spindle head of the tapping machine cannot adapt to the position of the workpiece in multiple directions, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

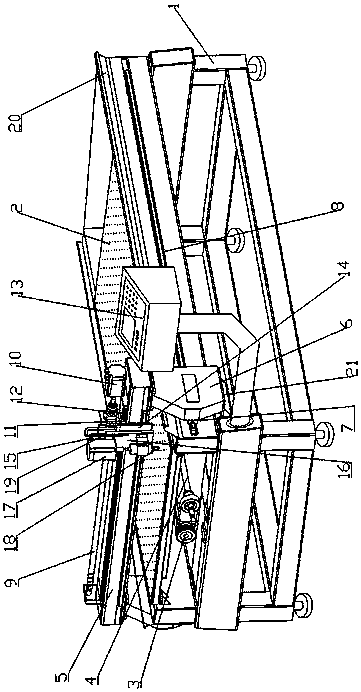

[0013] Embodiment: a kind of high-precision numerical control tapping machine of this example, as figure 1 , there is a frame 1, the frame is provided with a table 2 for placing workpieces, a Y servo motor 3 is provided under the table, the Y servo motor is connected with a Y screw 4, and the Y screw is movably connected with a beam 5, and the two sides of the beam are set A crossbeam column 6 is arranged, and a crossbeam supporting plate 21 is arranged below the crossbeam column. A dust-proof board 20 is provided between the beam column and both sides of the table top, and the dust-proof board is positioned above the Y slider 7 . The Y slider 7 is fixed on the beam column, and the Y slider is slidably connected to the Y guide rails 8 on both sides of the table. The X screw rod 9 is arranged on the beam, and the X screw rod is connected to the X servo motor 10. The X screw rod is slidably connected to X slide block 11, X slide block is fixed with saddle 14, slides and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com