Clutching brake

A technology of brakes and clutches, which is applied to brake actuators, rotary printing machines, printing, etc., can solve the problems of machine equipment wear and parking inconvenience, and achieve the effects of small wear, reliable parking effect, and no safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

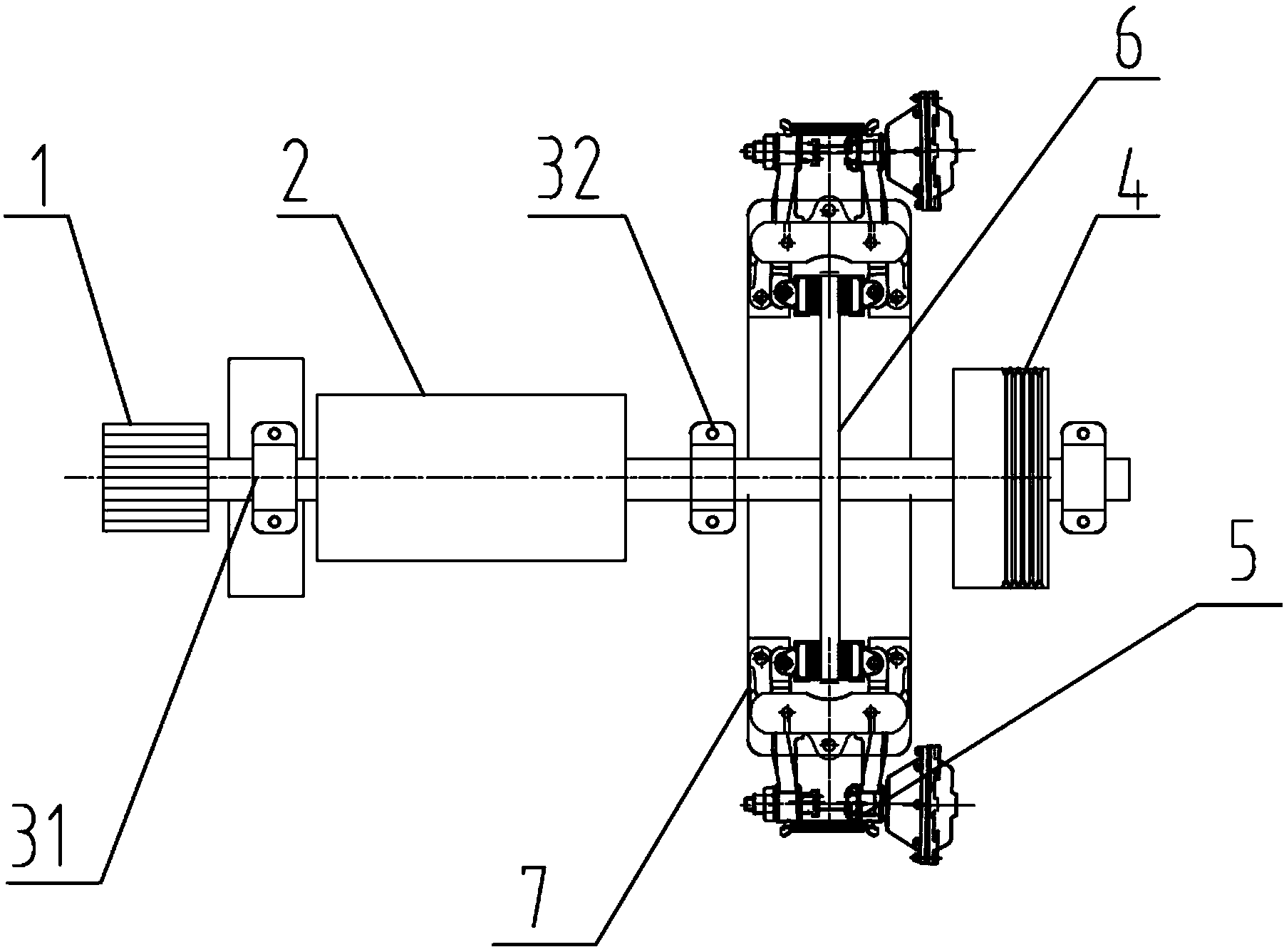

[0015] Such as figure 1 As shown, the clutch brake includes a printing press main body 1 and a driving shaft 2 connected to the printing press main body 1 through a first coupling 31. The driving shaft 2 is connected with a driven shaft 4, and the driven shaft 4 A pulley that can be connected to the belt is provided, and the driven shaft 4 is connected to the driving shaft 2 through the second coupling 32, and an annular mounting base 7 is installed between the second coupling 32 and the driven wheel 4. An annular brake wheel 6 is disposed on the seat 7, and a pneumatic actuator 5 is also connected to the installation base 7, and the pneumatic actuator 5 controls the engagement and release of the brake wheel 6.

[0016] Preferably, the annular brake wheel 6 is meshed with the driven wheel 4 through gears.

[0017] When the present invention works, the remote microcomputer is connected with the pneumatic actuator 5 in advance, and the brake air pressure and the release air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com