Hydraulic device for automobile braking energy recovery

A braking energy recovery and energy recovery technology, applied in the field of hydraulic devices, can solve problems such as high cost and complex structure, and achieve the effects of simplifying algorithms, improving work efficiency, and improving braking energy recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

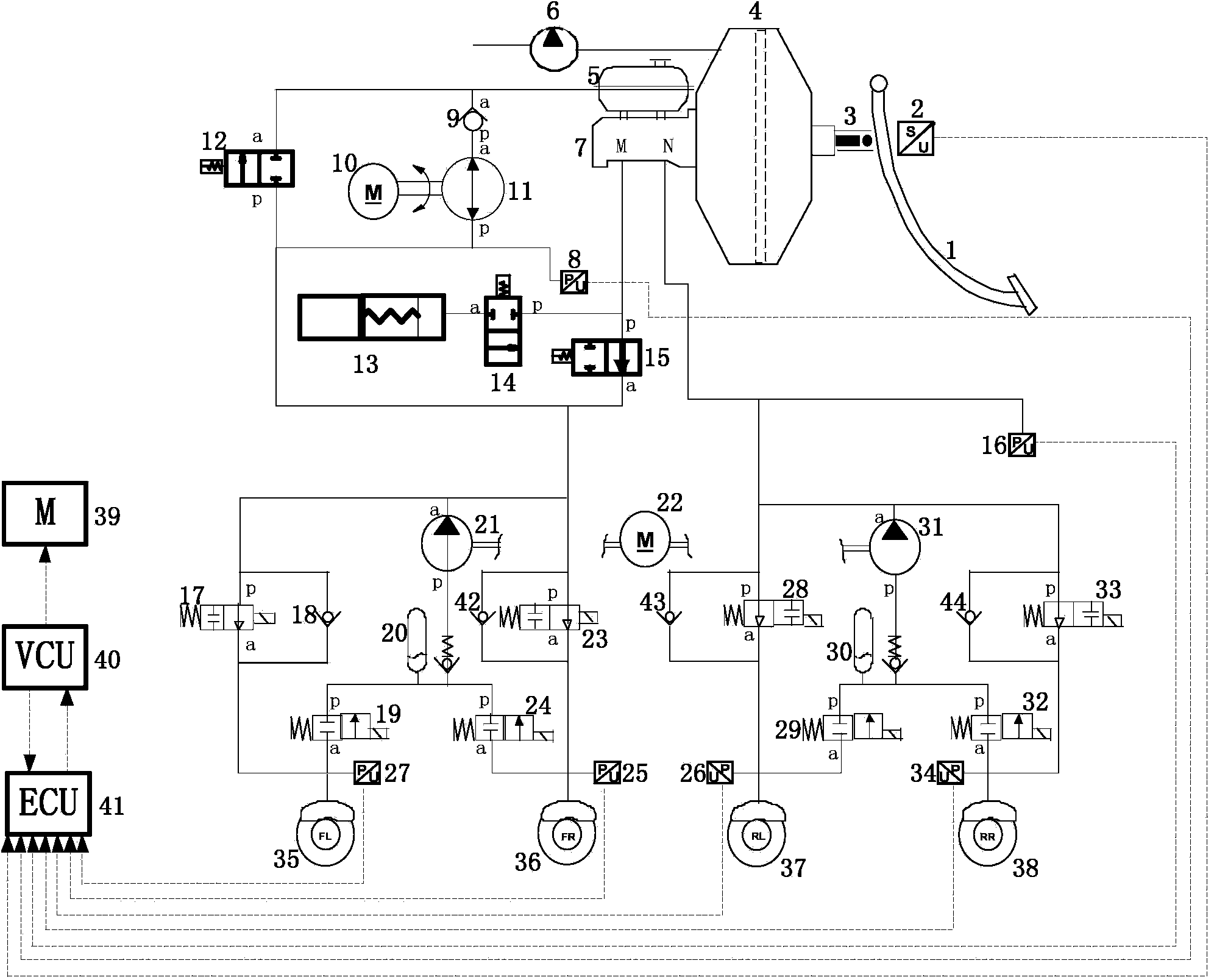

[0033] refer to figure 1 , The hydraulic device for recovering the braking energy of the vehicle according to the present invention includes a master cylinder vacuum booster assembly, a hydraulic control unit for braking energy recovery, an ABS hydraulic control unit and an electronic control device.

[0034] The master cylinder vacuum booster assembly includes a brake pedal 1 , a front end ejector rod 3 of the vacuum booster, a vacuum booster 4 , an oil pot 5 , a vacuum pump 6 and a brake master cylinder 7 . Wherein the function of the vacuum pump 6 is to simulate the negative pressure source of the engine intake pipe of the original car.

[0035] The brake pedal 1 selection pedal ratio is 3.5. Vacuum pump 6 selects a vacuum pump that can reach a vacuum degree of 40-67kPa. The diameter of the brake master cylinder is 23.6mm.

[0036] The top of the brake pedal 1 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com