Swimming ring and manufacturing method thereof

A swimming ring and weight percentage technology, applied in the field of swimming rings, can solve the problems that the surface of the swimming ring has no antibacterial effect, easy to retain bacteria, bacteria enter the skin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

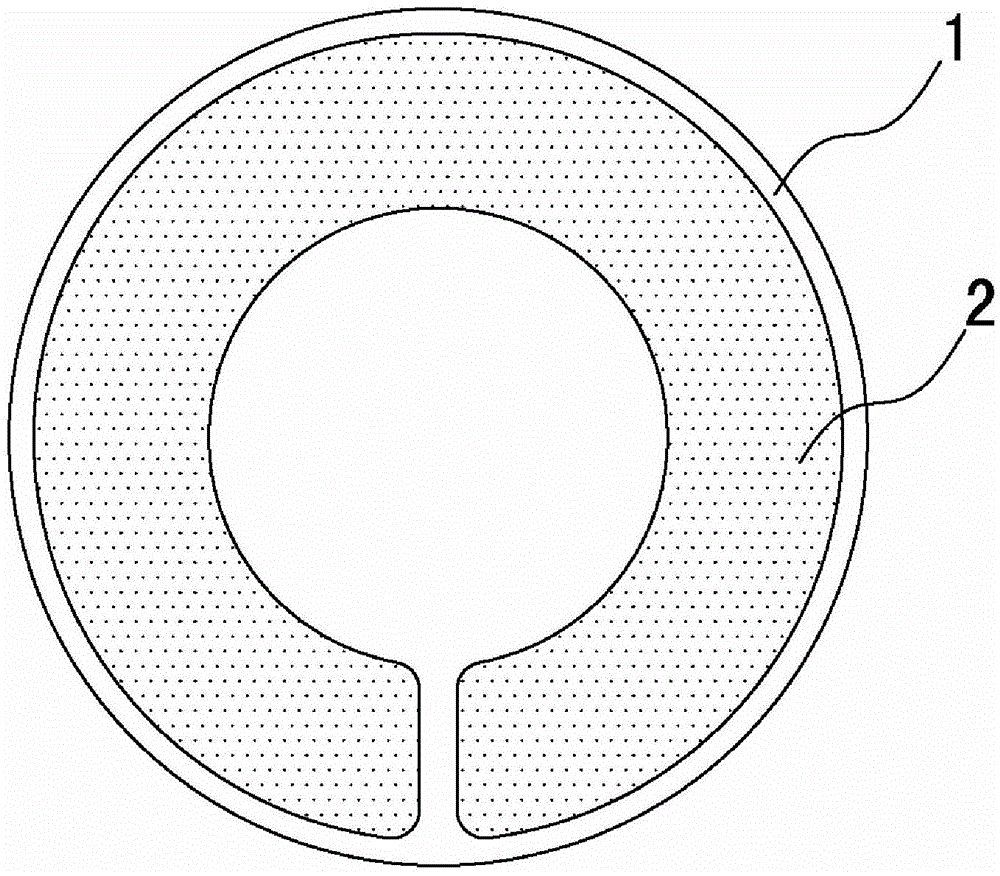

Image

Examples

Embodiment 1

[0037] Use PVG\PVC to make the swimming ring body: After the swimming ring body is made, take the following printing ink materials: PVC-vinyl acetate copolymer 20%, butyl acetate 20%, cyclohexanone 60%, and the above inks are added by 2-5% of the mixture composed of the following weight ratio: 0.01% silver element, 94.99% propylene glycol, 3% glycerol, 2% polyvinylpyrrolidone. Stir at high speed at room temperature, and after fully mixing, perform full-surface transparent printing on the surface of the swimming ring.

Embodiment 2

[0039] Use PVG\PVC to make the swimming ring body: After the swimming ring body is made, take the following printing ink materials: PVC-vinyl acetate copolymer 10%, butyl acetate 10%, cyclohexanone 80%, and the above inks are added by 2-5% of the mixture composed of the following weight ratio: 0.06% silver element, 94.94% propylene glycol, 3% glycerol, 2% polyvinylpyrrolidone. Stir at high speed at room temperature, and after fully mixing, perform full-surface transparent printing on the surface of the swimming ring.

Embodiment 3

[0041] Use PVG\PVC to make the swimming ring body: After the swimming ring body is made, take the following printing ink materials: PVC-vinyl acetate copolymer 30%, butyl acetate 30%, cyclohexanone 40%, and the above inks are added by 2-5% of the mixture composed of the following weight ratio: 0.01% silver element, 94.99% propylene glycol, 3% glycerol, 2% polyvinylpyrrolidone. Stir at high speed at room temperature, and after fully mixing, perform full-surface transparent printing on the surface of the swimming ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com