Biodegradable Mg-Zn-Ag layered composite material and preparation method thereof

A layered composite material and composite material technology are applied in the field of biodegradable Mg-Zn-Ag layered composite materials and their preparation, which can solve the problems of slow degradation, excessive corrosion, and high elastic modulus, and achieve good durability. , strong antibacterial properties, good mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

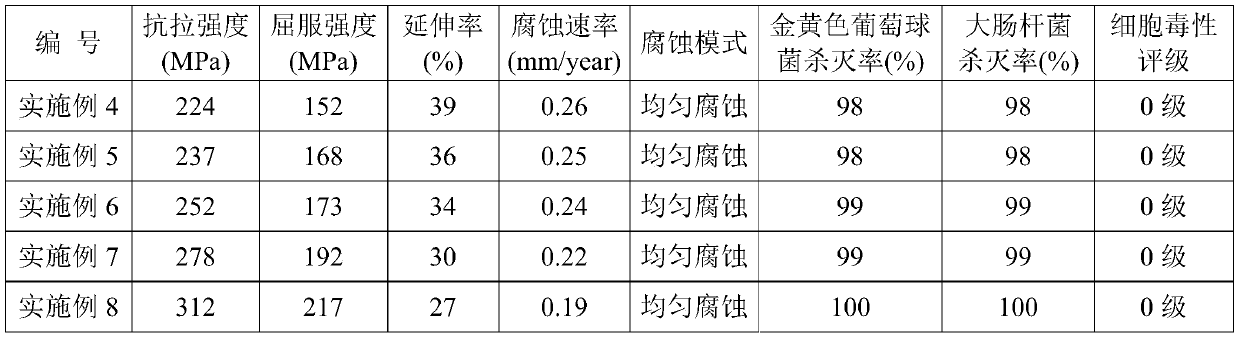

Examples

Embodiment 1

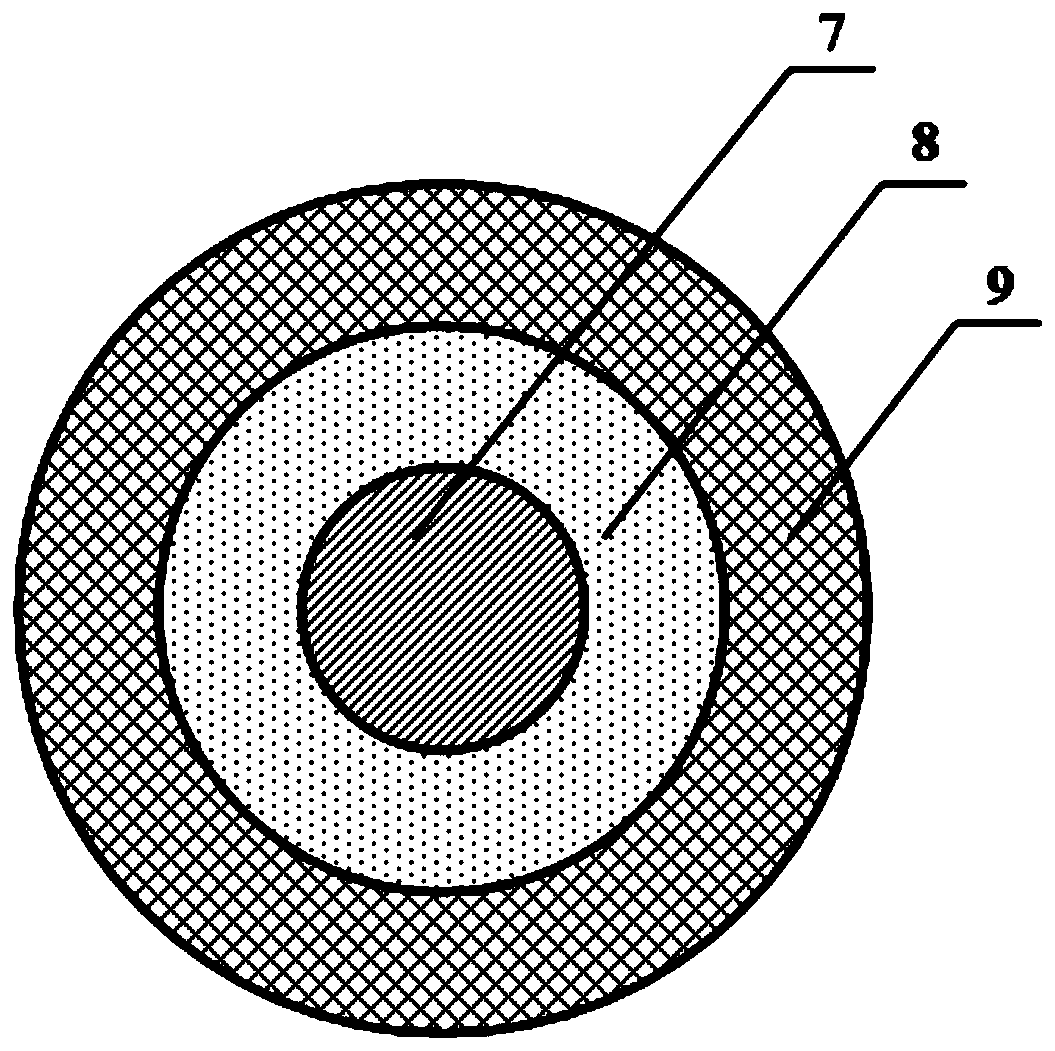

[0068] This example provides a biodegradable Mg-Zn-Ag layered composite material, which has an outer layer, a middle layer and an inner layer connected in sequence, the outer layer is a silver alloy, and the middle layer is a zinc alloy. The inner layer is a magnesium alloy, and the composite material includes the following components in volume percentage:

[0069] 10-25% of the silver alloy,

[0070] 20-35% of the zinc alloy,

[0071] The balance is the magnesium alloy.

[0072] The composite material in this example has a total of 3-layer structure, namely the inner layer, the middle layer and the outer layer. The form of the 3-layer structure makes the composite material have a more complete functional level, and each layer in the composite material is made of alloy , Compared with pure metals, alloys have better performance and use effects. The elements used in each layer alloy of the composite material of the present application are Ca, Zr and Sr, and each layer alloy ...

Embodiment 2

[0074] This example provides a biodegradable Mg-Zn-Ag layered composite material, which has an outer layer, a middle layer and an inner layer connected in sequence, the outer layer is a silver alloy, and the middle layer is a zinc alloy. The inner layer is a magnesium alloy, and the composite material includes the following components in volume percentage:

[0075] The silver alloy is 10-25%, the zinc alloy is 20-35%, and the balance is the magnesium alloy.

[0076] Wherein, the silver alloy includes at least one alloying element in Ca, Zr and Sr, specifically:

[0077] Ca 0.1-3.5%, and / or Zr 0.1-1.5%, and / or Sr 0.1-5.0%, and the balance is Ag.

[0078] As a preferred version, the silver alloy comprises the following components in mass percent:

[0079] Ca 0.3-0.8%, Zr 0.3-0.8%, Sr 1.0-2.0%, and the balance is Ag.

[0080] Zinc alloys include at least one alloying element of Ca, Zr and Sr, specifically:

[0081] Ca 0.1-3.5%, and / or Zr 0.1-1.5%, and / or Sr 0.1-5.0%, and the ...

Embodiment 3

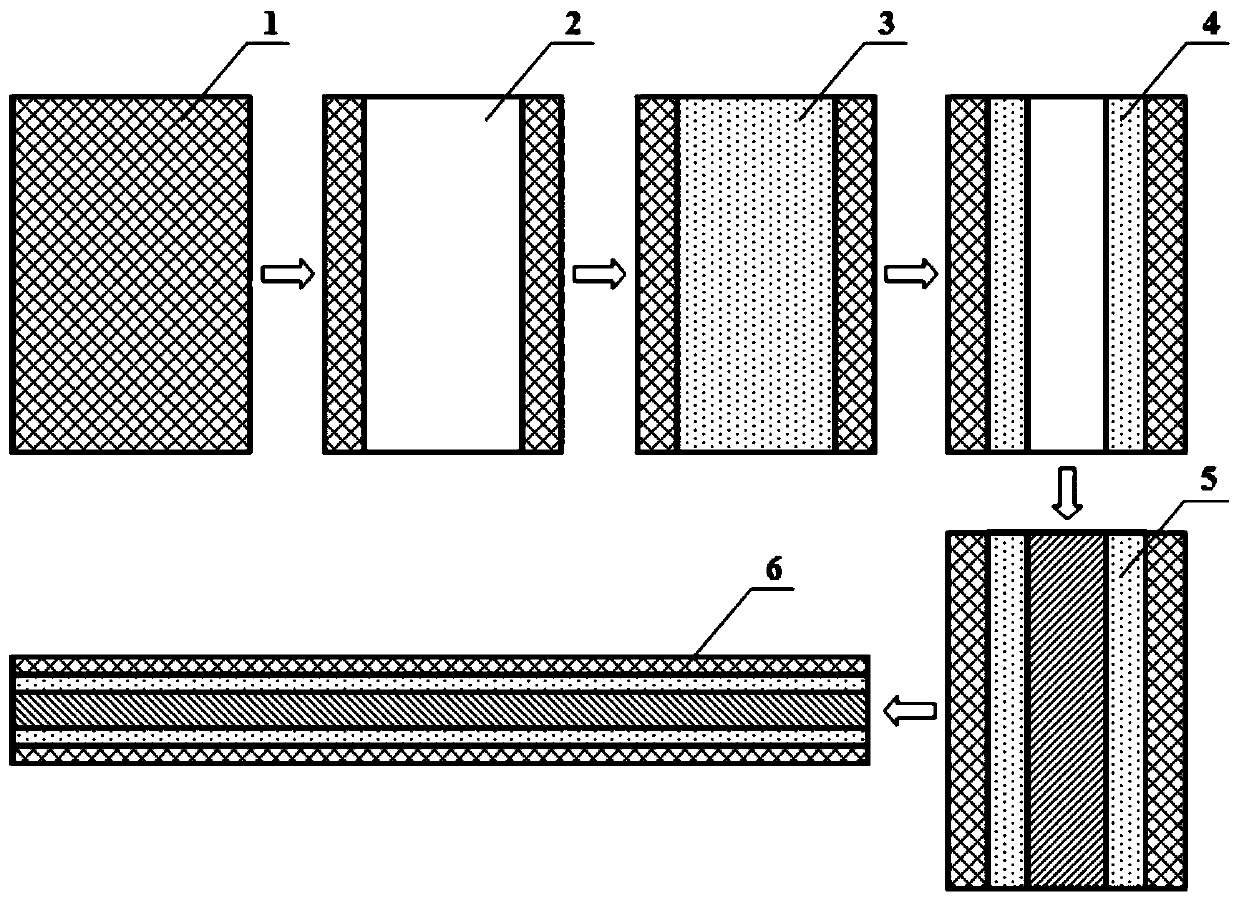

[0089] This example provides the preparation method of biodegradable Mg-Zn-Ag layered composite material, and the steps include:

[0090] After melting the zinc alloy, casting it into the silver alloy hollow round ingot to obtain a Zn-Ag composite material round ingot;

[0091] Processing the Zn-Ag composite ingot into a Zn-Ag hollow ingot;

[0092] After melting the magnesium alloy, casting it into the Zn-Ag hollow round ingot to obtain a Mg-Zn-Ag composite material round ingot;

[0093] The Mg-Zn-Ag composite ingot is hot-extruded and then annealed to obtain the biodegradable Mg-Zn-Ag layered composite material.

[0094] Process such as figure 1 as shown, figure 1 Among them, 1 is silver alloy round ingot, 2 is silver alloy hollow round ingot, 3 is Zn-Ag composite material round ingot, 4 is Zn-Ag composite material hollow round ingot, 5 is Mg-Zn-Ag layered composite material round Ingot 6 is an extruded Mg-Zn-Ag layered composite material.

[0095] Among them, the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com