Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

A technology for direct coal liquefaction of oil and phenolic compounds, applied in the field of coal chemical industry, can solve problems such as poor effect, achieve broad application prospects, no waste water, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

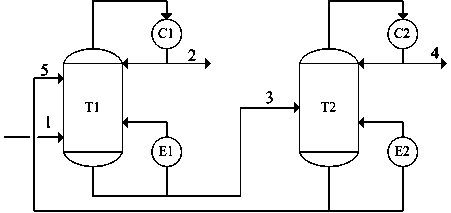

Image

Examples

Embodiment 1

[0035] In Example 1, the first phenol-rich distillate at 170-200°C uses a mixed solvent of sulfolane and triethylene glycol (mass ratio 1:1) as the No. 1 solvent, and the second phenol-rich distillate at 200-230°C uses triacetin The mixed solvent of ester and triethanolamine (mass ratio 2:1) was used as the No. 2 solvent.

[0036] Table 1 Dephenolization process conditions of the first phenol-rich distillate at 170-200°C in Example 1

[0037] Process conditions Extractive distillation column T1 Recovery Tower T2 Number of plates 15 10 No. 1 solvent / first phenol-rich distillate (mass ratio) 1.2 - Reflux ratio 2 3 Tower top temperature ℃ 183.5 213.2 Bottom temperature °C 246.2 301.4 Tower top pressure MPa 0.101 0.101 Tower bottom pressure MPa 0.111 0.111

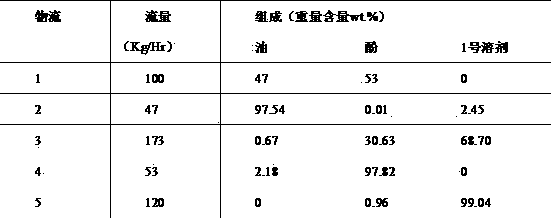

[0038] Table 2 Properties of various streams during dephenolization of the first phenol-rich distillate oil at 170-200°C in Example 1

[0039]

[0040] Tab...

Embodiment 2

[0045] In Example 2, the first phenol-rich distillate at 170-200°C uses sulfolane as the No. 1 solvent, and the second phenol-rich distillate at 200-230°C uses glycerol triacetate as the No. 2 solvent.

[0046] Table 5 Dephenolization process conditions of the first phenol-rich distillate at 170-200°C in Example 2

[0047] Process conditions Extractive distillation column T1 Solvent Recovery Tower T2 Number of plates 16 11 No. 1 solvent / first phenol-rich distillate (mass ratio) 1.3 - Reflux ratio 2 3 Tower top temperature ℃ 180.6 210.3 Bottom temperature °C 245.1 302.3 Tower top pressure MPa 0.101 0.101 Tower bottom pressure MPa 0.111 0.111

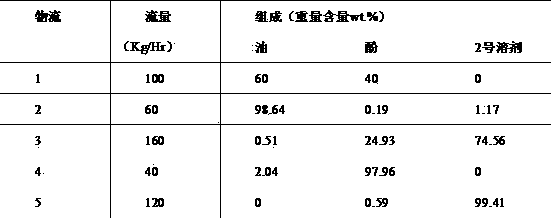

[0048] Table 6 Properties of various streams during dephenolization of the first phenol-rich distillate oil at 170-200°C in Example 2

[0049]

[0050] Table 7 Dephenolization process conditions of the second phenol-rich distillate at 200-230°C in Example 2

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com