Polyvinyl alcohol polymer film and process for producing same

A manufacturing method and polarizing film technology, applied to polarizing elements, coatings, instruments, etc., can solve undisclosed problems and achieve the effects of increased productivity, low cost, and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

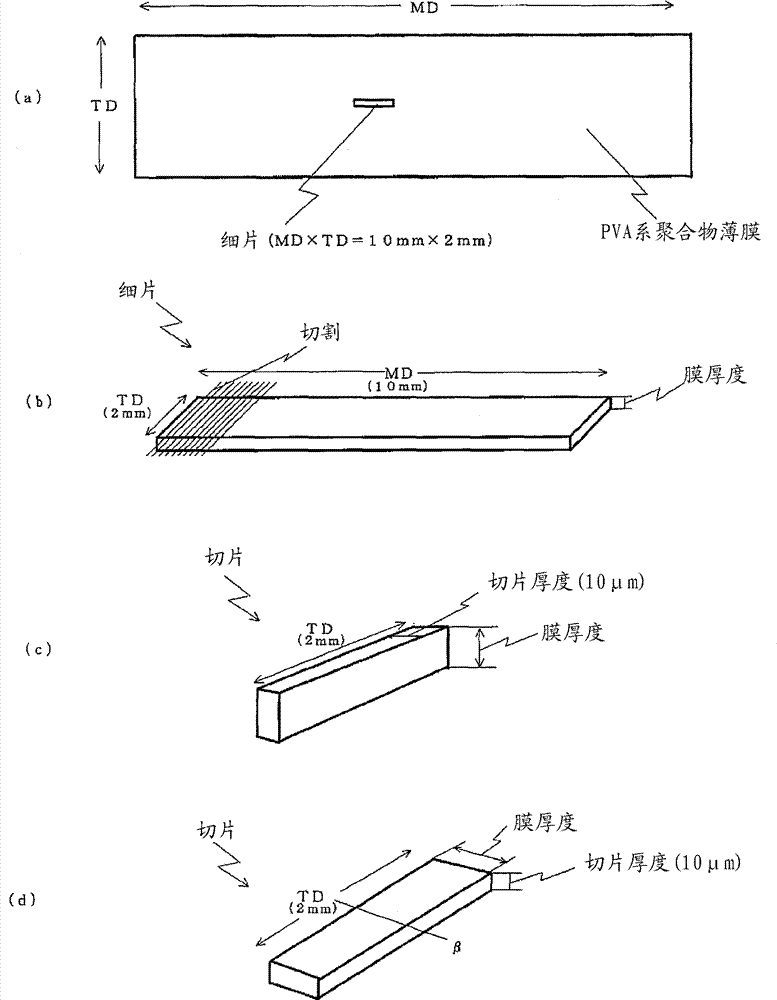

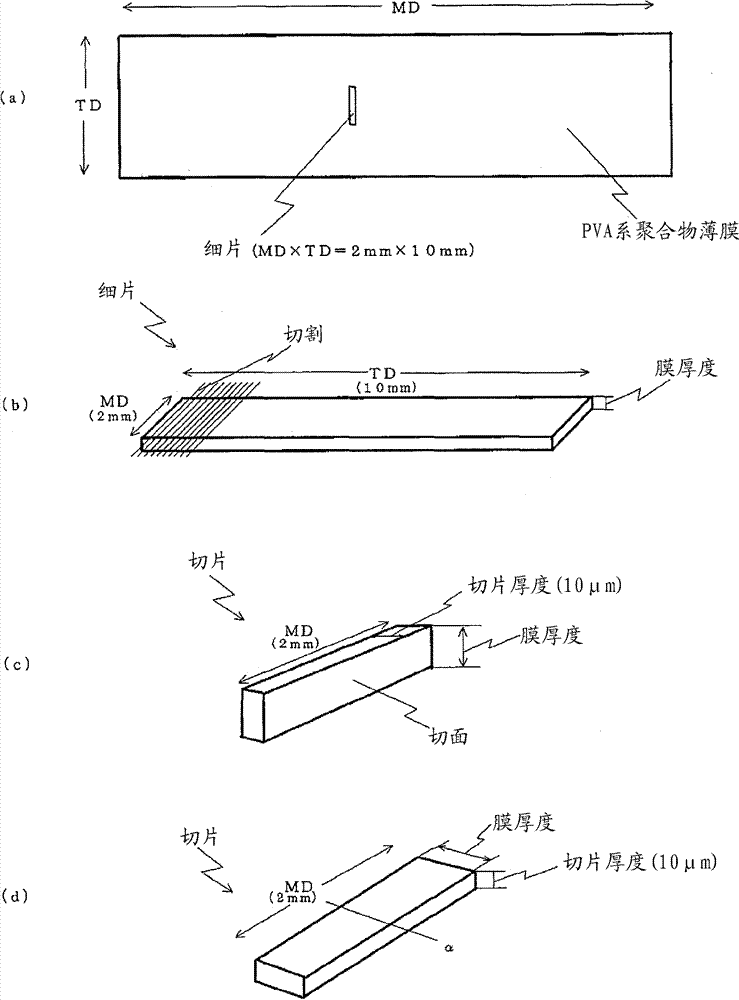

Method used

Image

Examples

Embodiment 1

[0206] (1) Manufacture of PVA film:

[0207] (i) The proportion of volatile components composed of 100 parts by mass of PVA obtained by saponification of polyvinyl acetate (saponification degree 99.9 mol%, polymerization degree 2400), 12 parts by mass of glycerin, 0.1 part by mass of lauric acid diethanolamide, and water The film-forming stock solution that is 66% by mass is discharged to the first drying roller (93° C. of surface temperature, peripheral speed (S 1 ) 16.7m / min), while spraying hot air of 90°C at a wind speed of 5m / sec on the first drying roller to the entire non-contact surface of the first drying roller, while drying until the moisture ratio reaches 18% by mass, then, from the first drying roller The first drying roll is peeled off, and the drying after the second drying roll is carried out under the condition of the roll surface temperature of about 85 ° C, so that the surface and back of any part of the PVA film are alternately contacted with each drying ro...

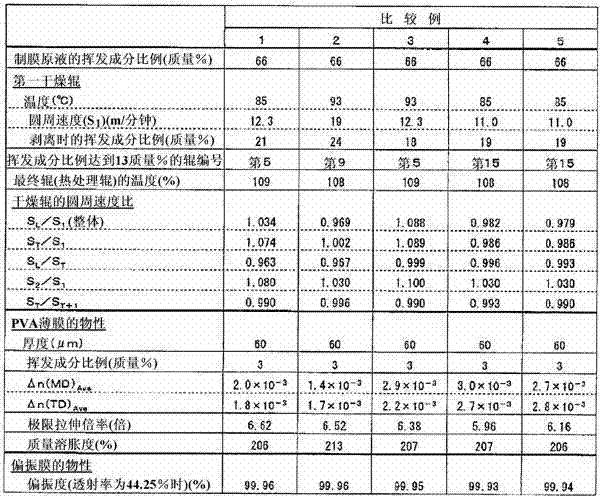

Embodiment 2~5

[0223] (1) In Example 1, a PVA film was produced in the same manner as in Example 1 (1) by changing the film-forming conditions when producing the PVA film as described in Table 1 below. However, in Example 2, 100 parts by mass of PVA obtained by saponification of polyvinyl acetate (saponification degree 99.9 mol%, polymerization degree 2400), 12 parts by mass of glycerin, diethyl laurate A film-forming stock solution having a volatile component ratio of 73% by mass consisting of 0.1 parts by mass of amide and water.

[0224] The Δn(MD) of each PVA film thus obtained was measured by the method described above. Ave , Δn(TD) Ave , mass swelling degree and ultimate stretch ratio, the results are shown in Table 1 below.

[0225] (2) Using a test piece in the longitudinal direction (MD)×width direction (TD)=10cm×5cm collected from the central portion of each PVA film obtained in the above (1) in the width direction (TD), carry out the same procedure as in Example 1. (2) The same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com