Inverted arch lining trolley, synchronous tunnel operating system and inverted arch synchronous lining method

A technology for lining trolleys and arches, which is used in tunnels, shaft linings, tunnel linings, etc., can solve the problems of unstable machine operation and poor adaptability, and achieve the effect of saving materials, improving production efficiency, and no construction interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

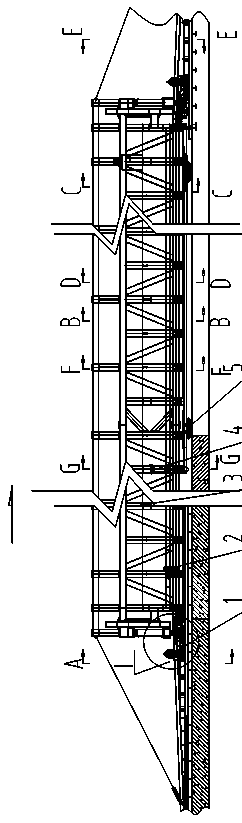

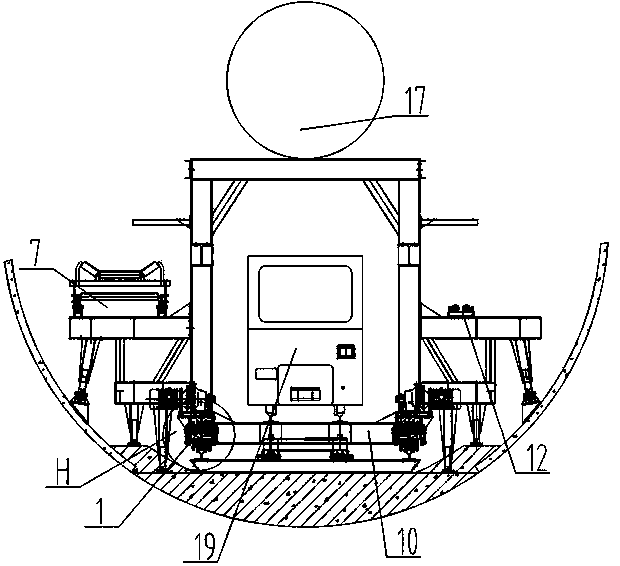

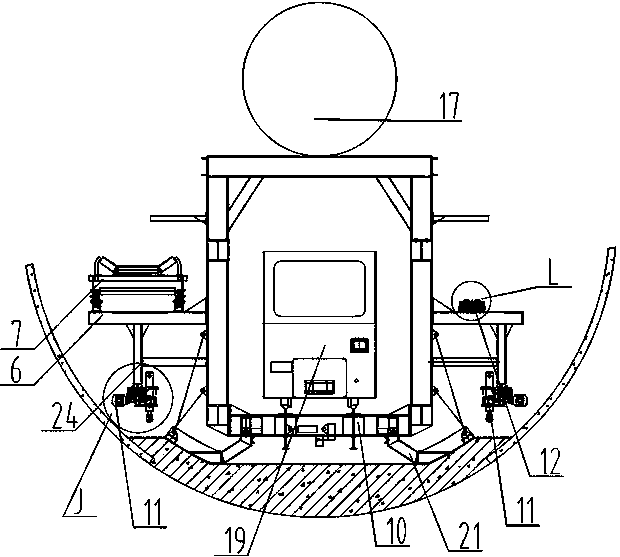

[0056] Embodiment 1 A synchronous tunnel operation system, see Figure 1 to Figure 8 , including the TBM set on the track, the inverted arch trolley (length 81.604m) and the side-top arch synchronous lining trolley arranged behind the inverted arch trolley. The inverted arch trolley is divided into an upper platform and a lower part On the stand, the ventilation duct 17 is arranged in the middle of the upper stand, the motor drive device 1 is installed on the lower stand, the lower stand includes a frame body 10 and a support 24, the support 24 is installed on the side of the frame body 10, and a belt is installed on the support 24 Machine 7, cables 12, pipelines and hydraulic devices are provided with traveling rails in the frame body 10, and the two ends of the traveling rails are provided with corresponding up-slope rails and down-slope rails, and the bottom of the frame body 10 is provided with its hinge support The connected side form 21 is equipped with a slide form 20 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap