Control method for reducing engine starting torsion

A control method and engine technology, applied in the direction of engine starting, engine components, machine/engine, etc., can solve problems such as high cost, polluting engine, engine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

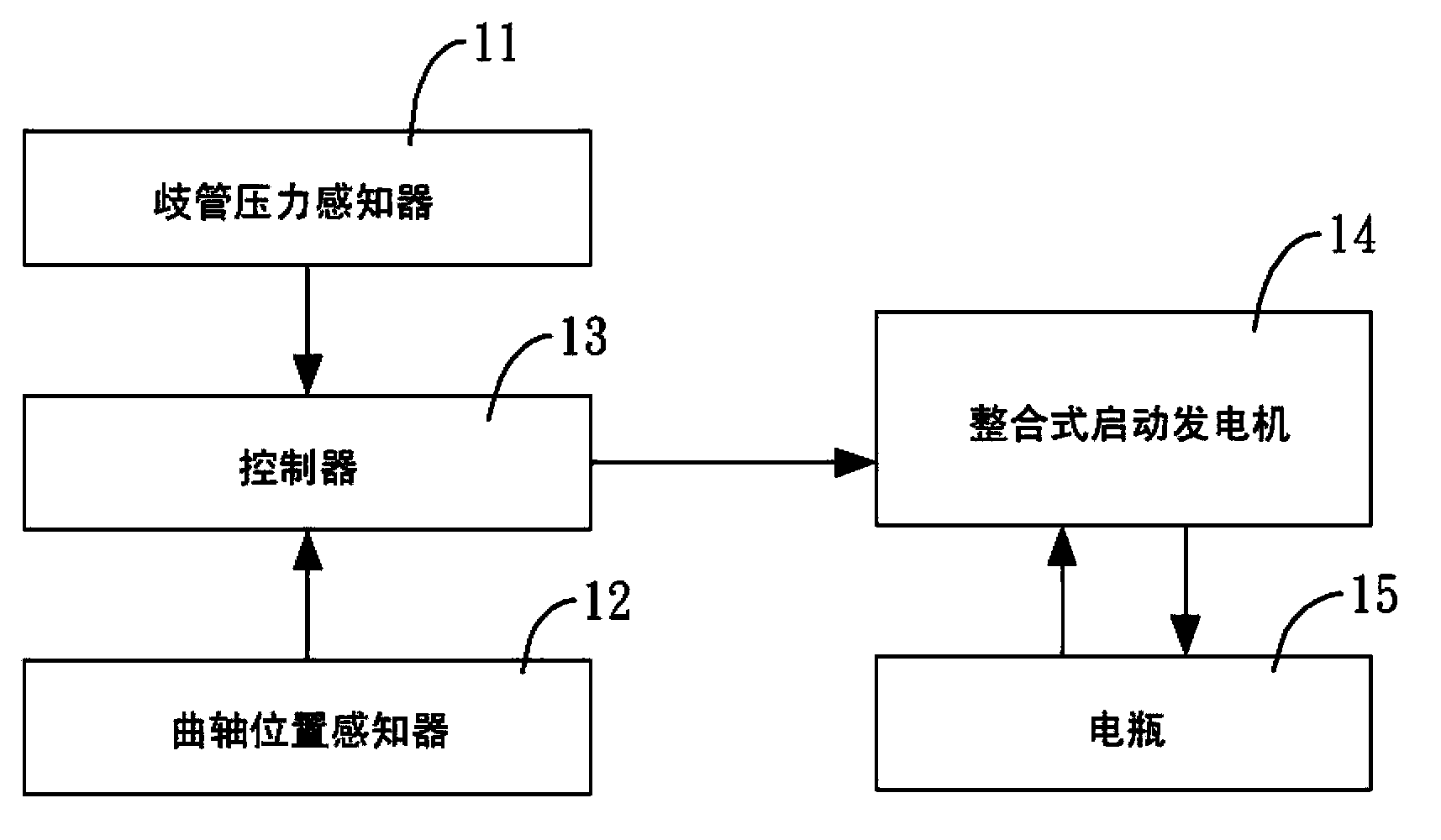

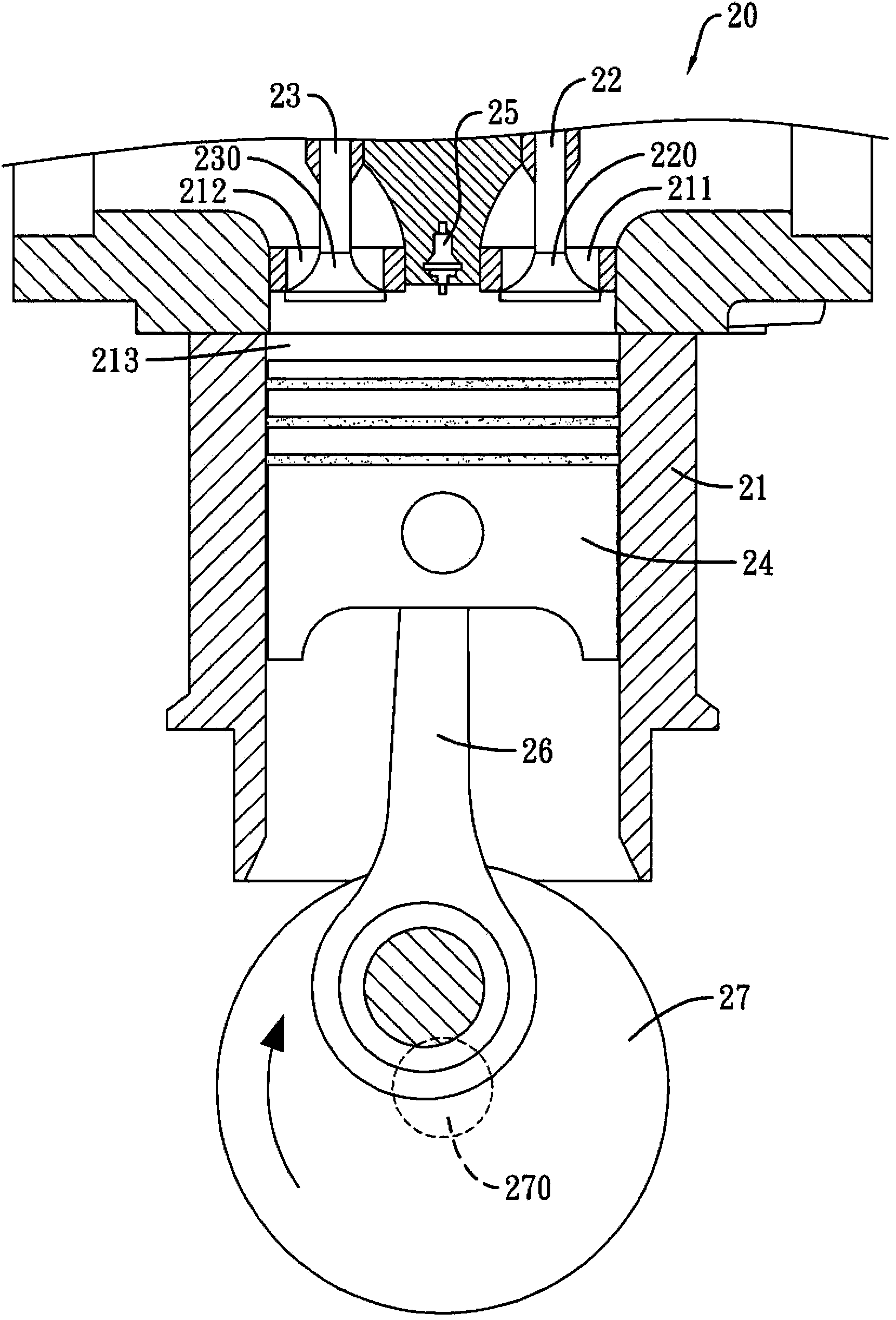

[0040] Please refer to figure 1 As shown, the device for implementing the method of the present invention includes a manifold pressure sensor 11 , a crankshaft position sensor 12 and a controller 13 . Please refer to figure 2As shown in the schematic diagram of the engine 20, the manifold pressure sensor 11 is arranged in the intake pipe 211 to sense the gas pressure in the intake pipe 211, and the crankshaft position sensor 12 is arranged outside the end of the crankshaft 27 to sense the gas pressure according to the crankshaft 27. The rotation state produces a square wave signal. The controller 13 is electrically connected to the manifold pressure sensor 11 and the crankshaft position sensor 12 to receive the pressure value and the square wave signal respectively. The structure of the engine 20 and the way of judging the angle of the crankshaft 27 are known technologies, and will not be described here. Let me repeat.

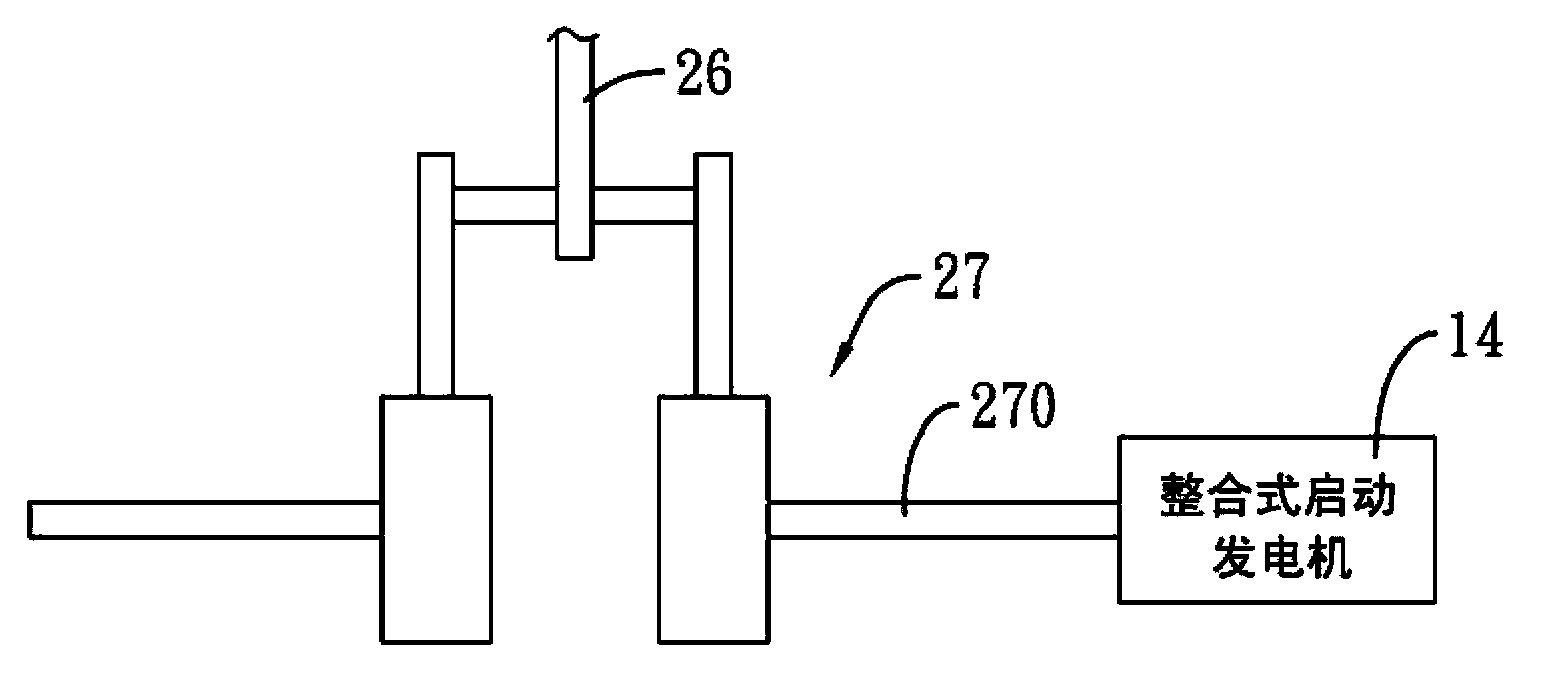

[0041] Please refer to image 3 As shown, the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com