Internal suspension core optical fiber grating temperature self-compensation microfluidic sensor and internal suspension core optical fiber

An automatic compensation and fiber grating technology, which is applied in cladding optical fiber, optical waveguide and light guide, and phase influence characteristic measurement, etc., can solve the problems of unfavorable device integration, increase sampling amount, etc., achieve simple structure, improve detection accuracy, and accurate detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples describe the present invention in more detail.

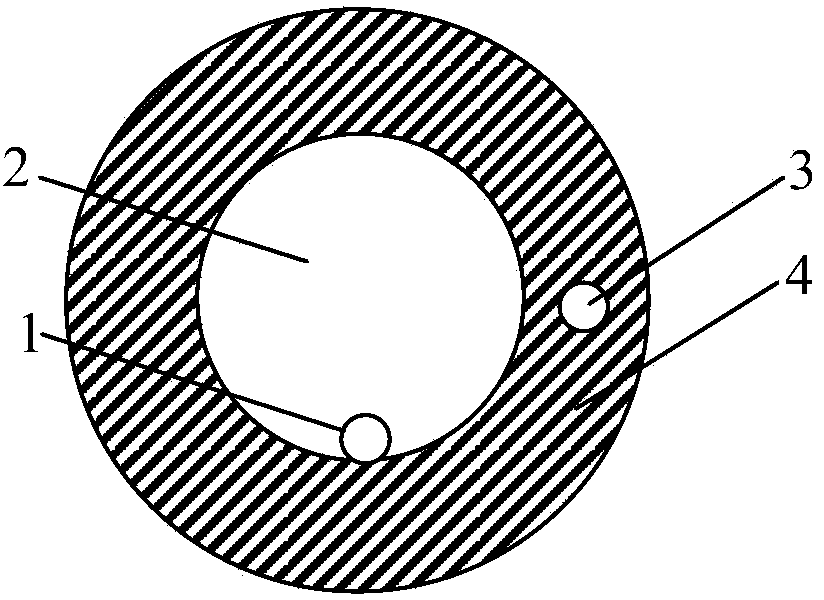

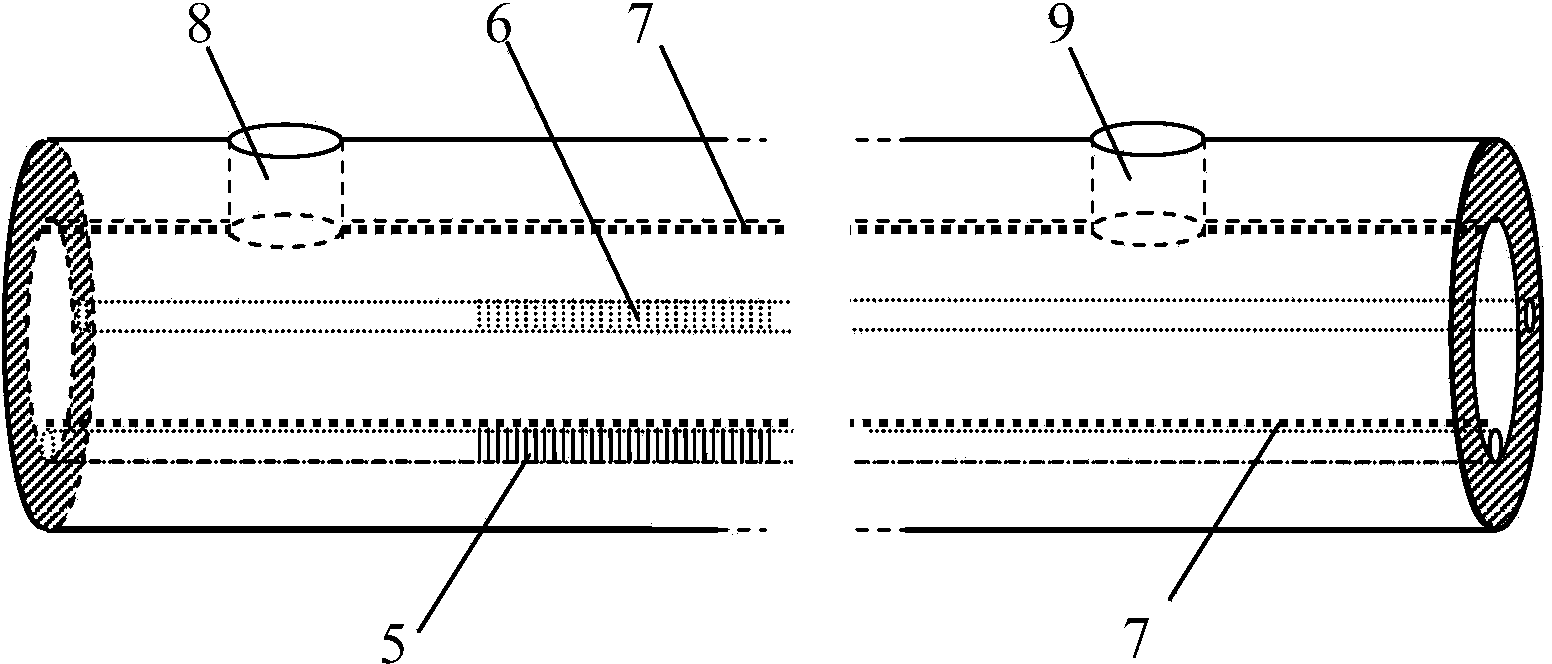

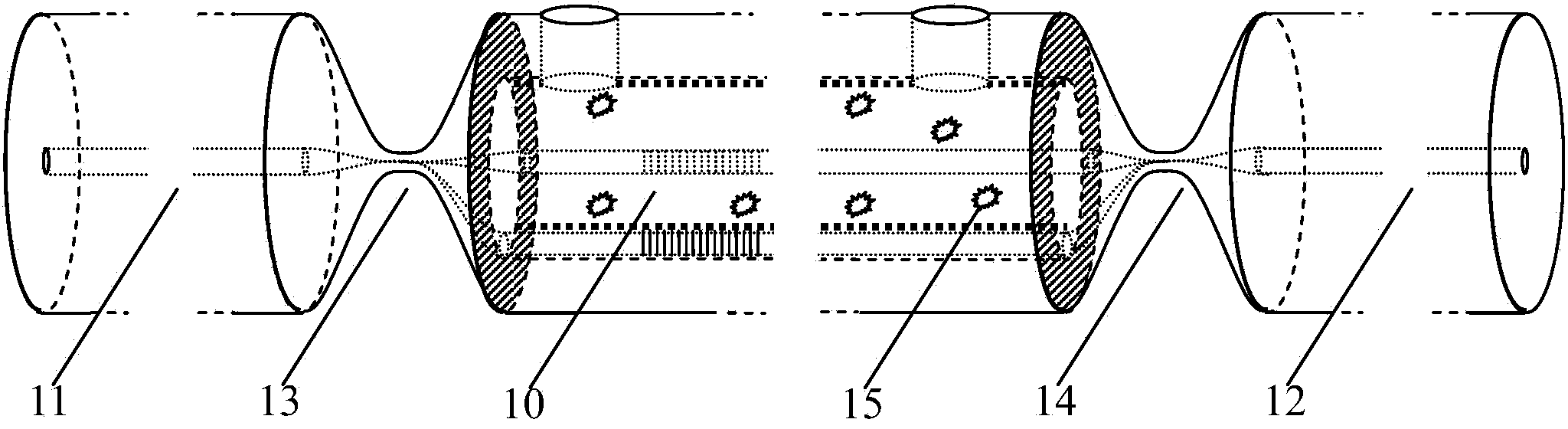

[0018] combine figure 1 , the structural feature of the inner suspension core fiber is that it has two cores, wherein the core 1 is located on the inner wall of the inner hole 2 of the fiber, and the core 3 is located inside the ring-shaped cladding 4 of the fiber, and the diameter of each core is 5 μm , the diameter of the entire fiber is 125 μm. Most of the core 1 located on the inner surface of the fiber tunnel is exposed outside the cladding, and the area exposed outside the cladding 4 is 90% of the surface area of the core. combine figure 2 As shown, fiber gratings 5 and 6 with the same structure are written at the same longitudinal position on the two cores, wherein the fiber grating 5 on the core 1 is used as the sensing unit, and the fiber grating 6 on the core 3 is used as the reference than unit. The sensing fiber grating 5 can be directly exposed to the micro-flow of the object t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com