Analysis method for measuring steel part carburized layer by laser induction spectrum

A technology of laser induction and analysis method, which is applied in the direction of material excitation analysis, etc., to achieve the effect of easy processing, wide application range, and comprehensive analysis and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Taking the carburized layer analysis of the helical tooth surface of the gear shaft after carburizing and quenching as an example, the specific analysis steps are as follows:

[0043] (a) Remove one of the helical teeth by electric spark cutting, and cut a section sample perpendicular to the meshing surface in the middle;

[0044] (b) The cross-section sample is inlaid by cold mounting method, and the inspection surface is ground and polished in the metallographic sample preparation equipment, rinsed with running tap water and alcohol in turn, and dried, then put the sample in the desiccator;

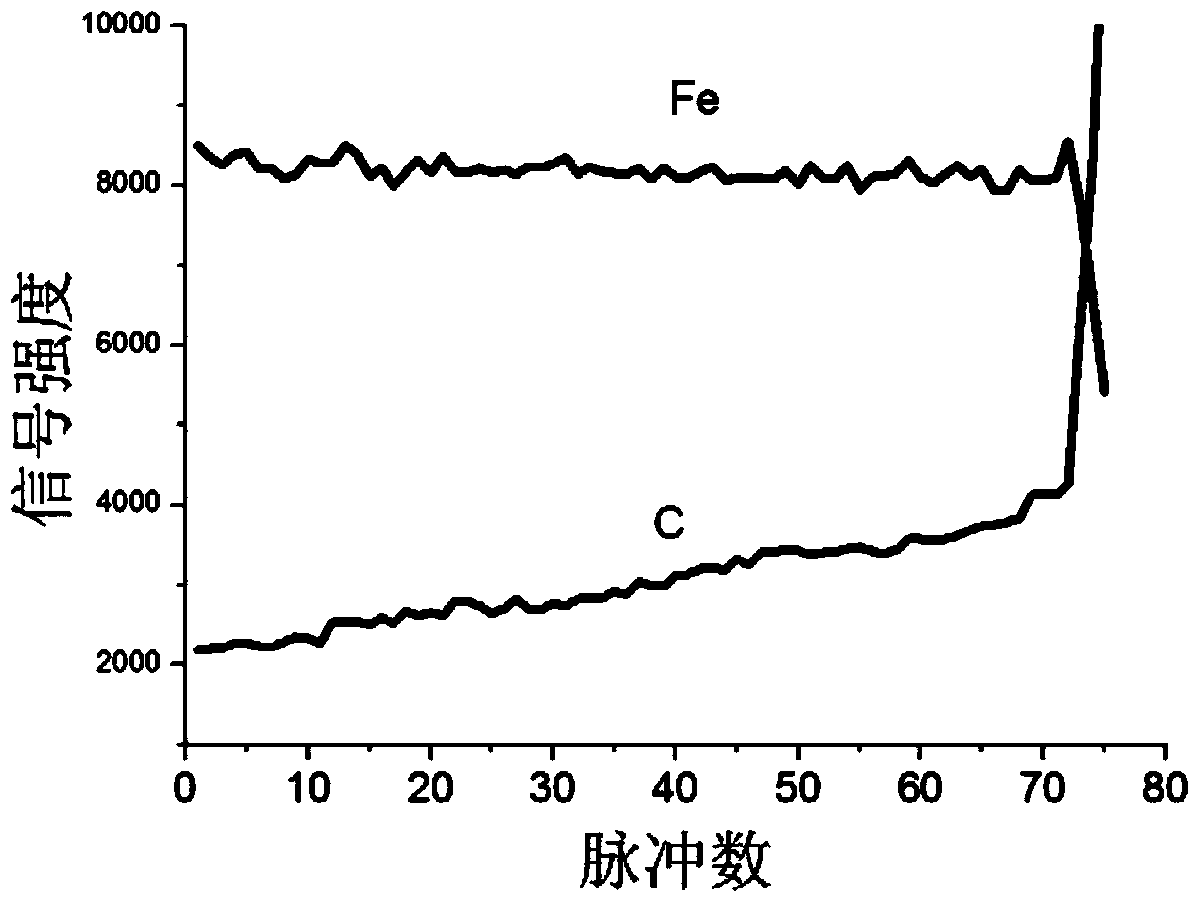

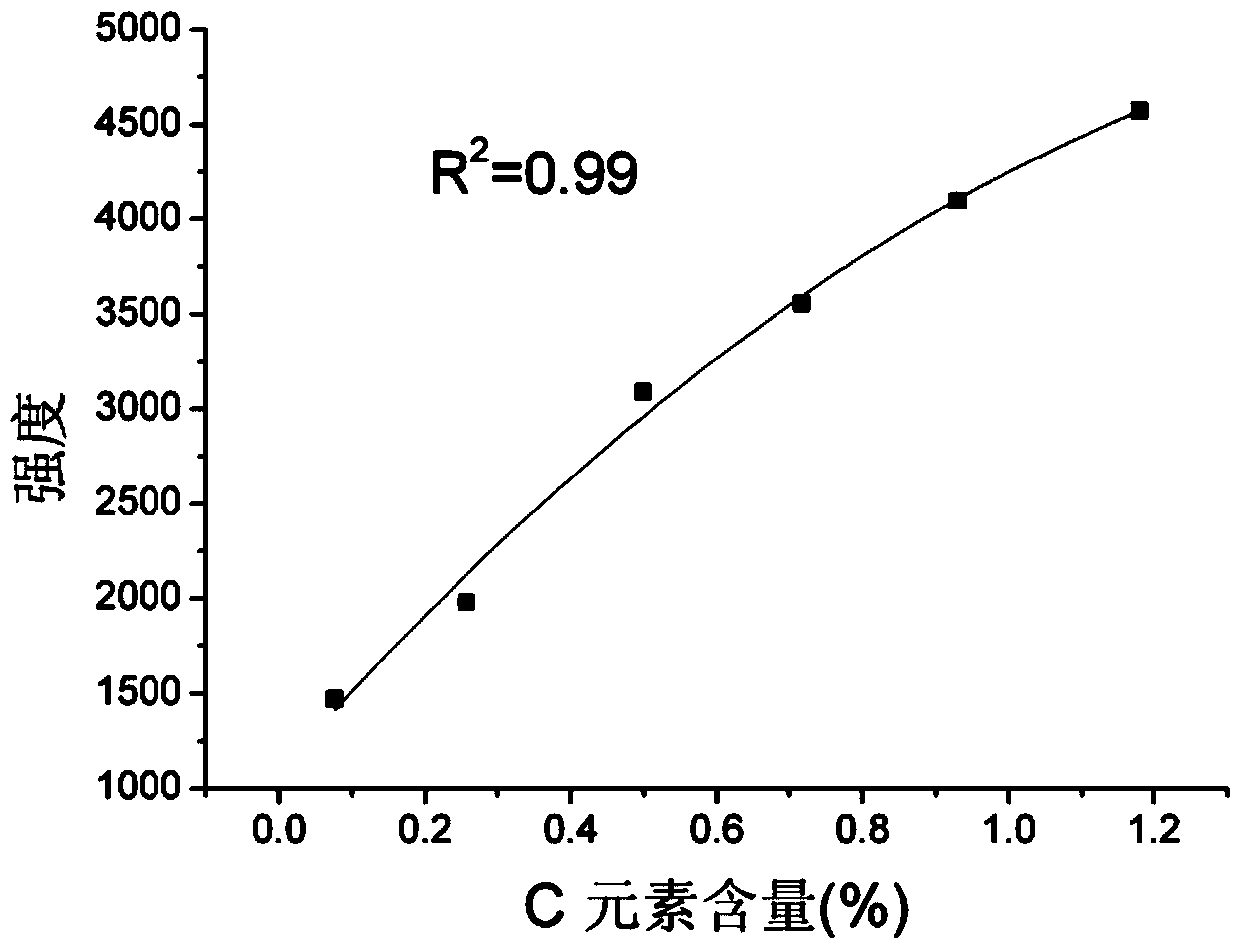

[0045](c) Adjust the laser-induced spectrometer to the best analysis state, adjust the position and angle of the sample, and conduct line-scanning analysis at the predetermined test position perpendicular to the surface. The scanning step of the stepping motor is 80 microns, and the total scanning length is 6mm. Simultaneously collect the signals of C and Fe elements during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com