Modularization multi-level current converter bridge arm current direction measuring device and judgment method

A modular multi-level, current direction technology, applied in the direction of current indication, electronic circuit testing, voltage polarity indication, etc., can solve the problem of inability to accurately measure electromagnetic current transformers, reduce reliability, and improve the current direction detection device Complexity and cost issues, to achieve the effect of solving development or selection difficulties, improving reliability, and reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

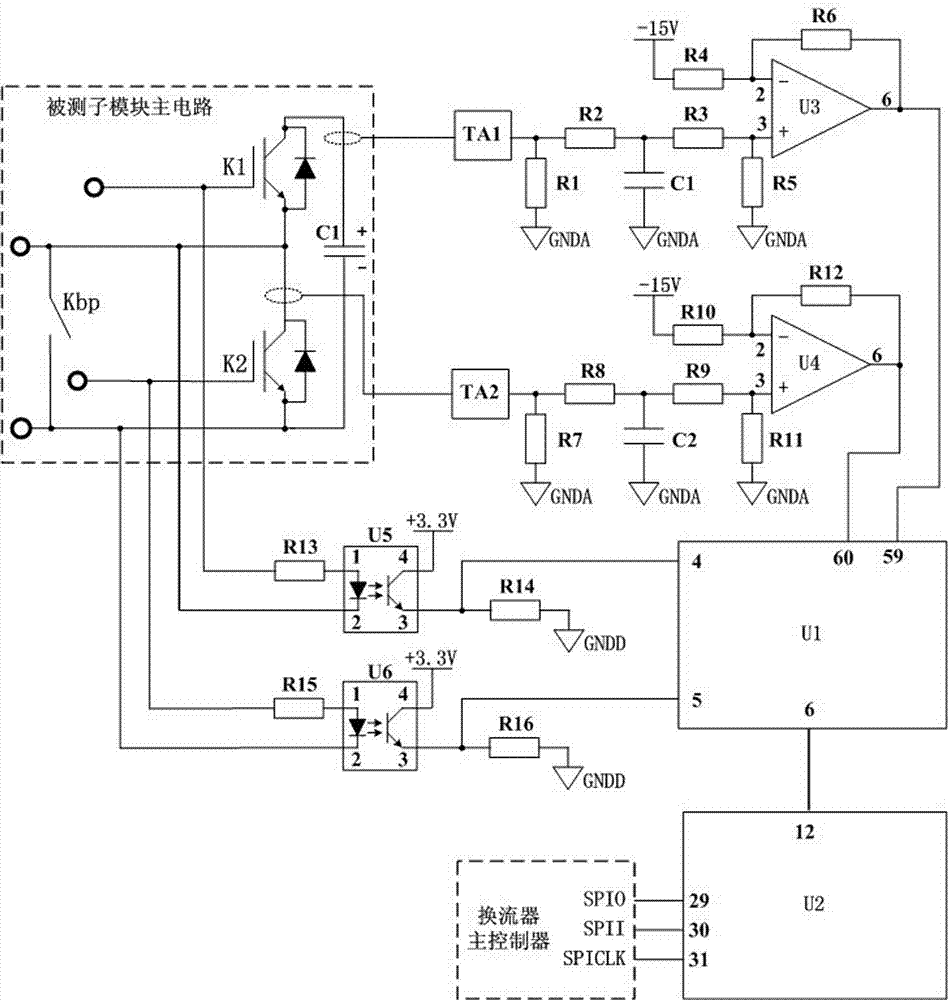

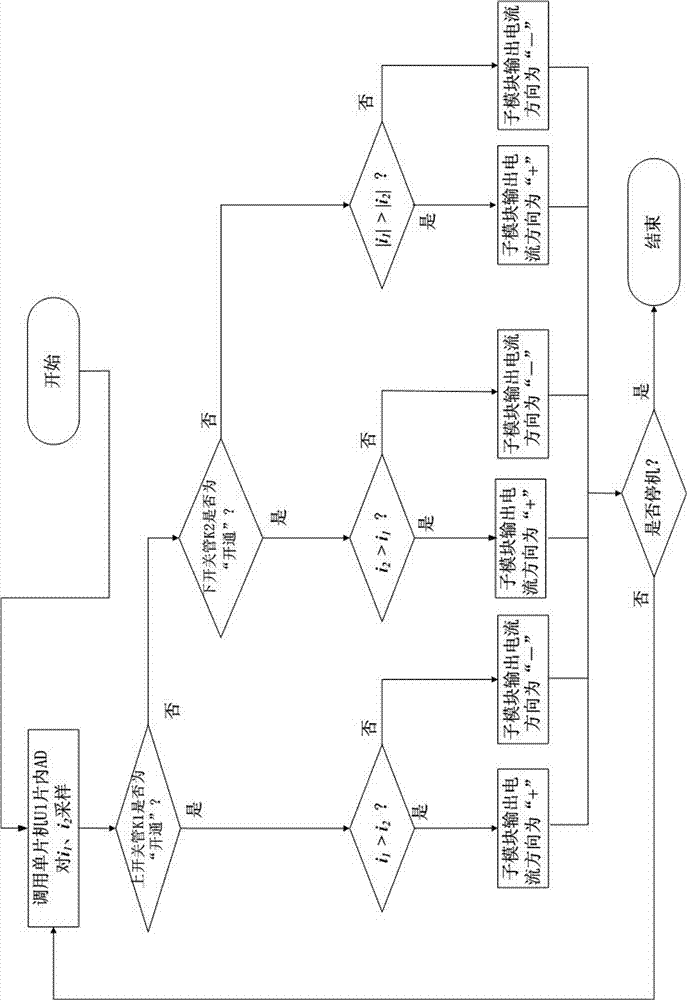

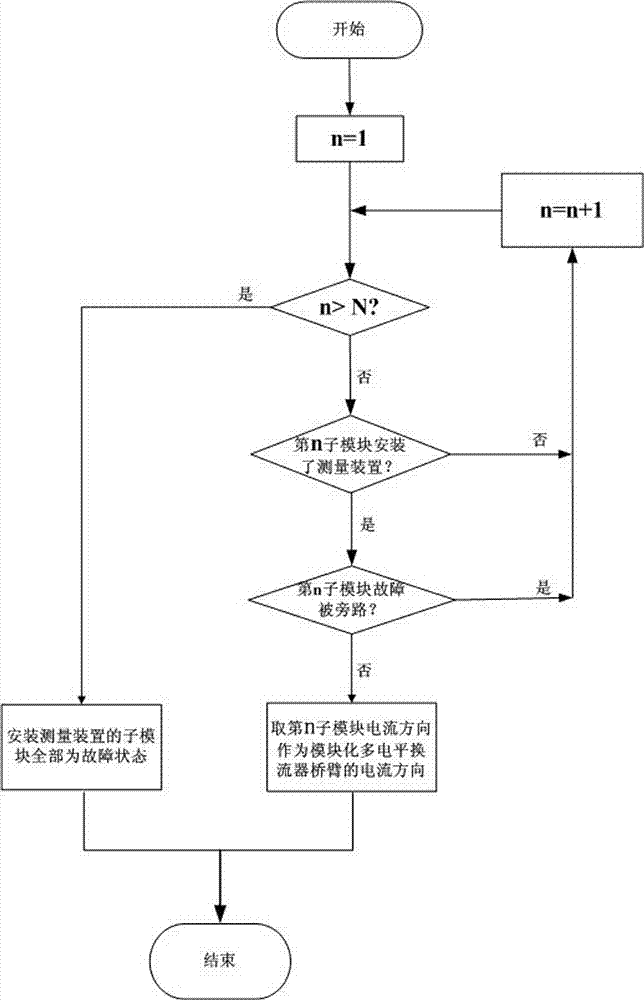

[0036] Depend on Figure 1-5 It can be seen that this embodiment includes a first single-chip microcomputer U1, a second single-chip microcomputer U2, a first current sensor TA1, a second current sensor TA2, a first operational amplifier U3, a second operational amplifier U4, a first photocoupler U5, a second photoelectric coupler Coupler U6, resistors R1-R16 and capacitors C1-C2;

[0037] The primary side of the first current sensor TA1 is set on the lead-out line of the collector of the upper switching tube K1 of the sub-module under test; the primary side of the second current sensor TA2 is set on the collector of the lower switching tube K2 of the sub-module under test lead-out line;

[0038] The resistor R2 and the resistor R3 are connected in series between the output terminal of the first current sensor TA1 and the non-inverting input terminal 3 pin of the first operational amplifier U3; the output terminal 6 pin of the first operational amplifier U3 Connect the AD si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com