Vacuum sucker for TSV silicon wafer

A vacuum suction cup and vacuum chamber technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of weak adsorption, difficult surface deformation, small contact area, etc., to increase the adsorption firmness and good processing performance. , Compression and rebound effect with high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

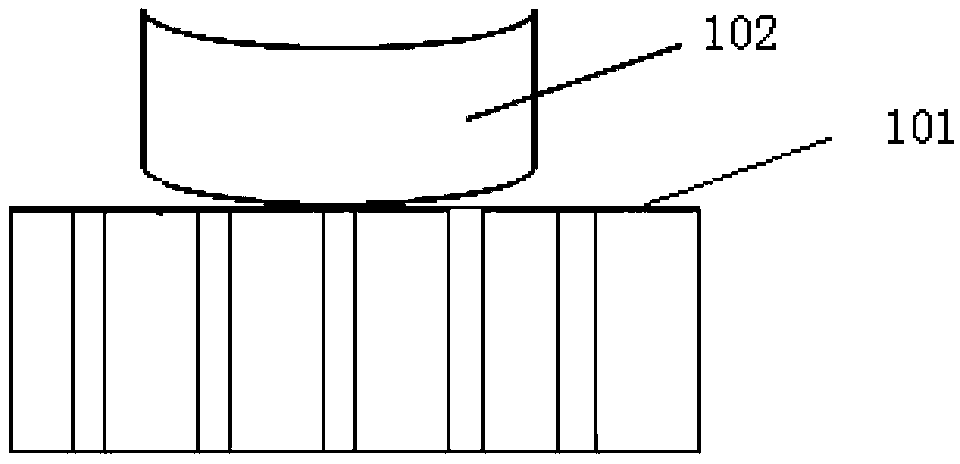

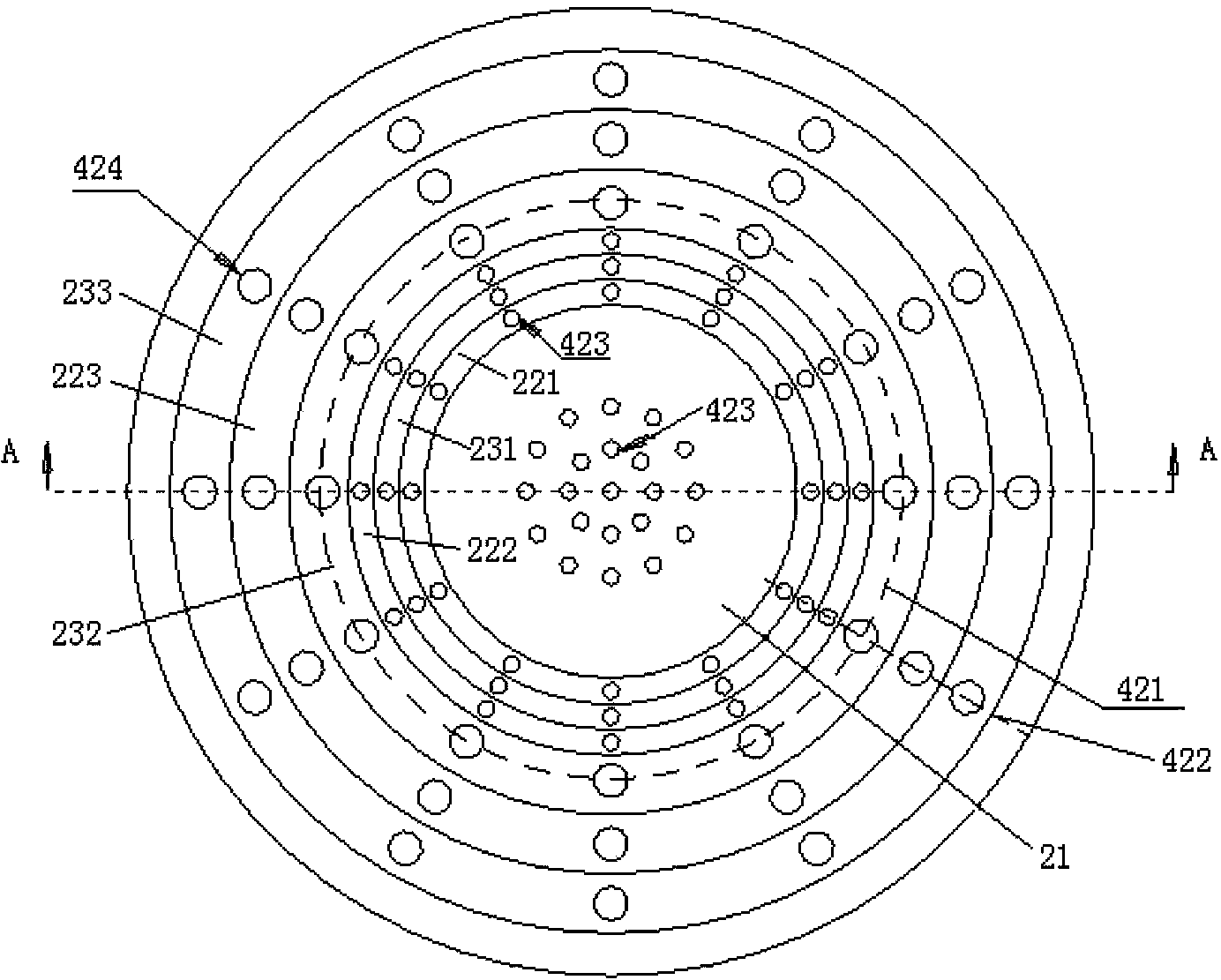

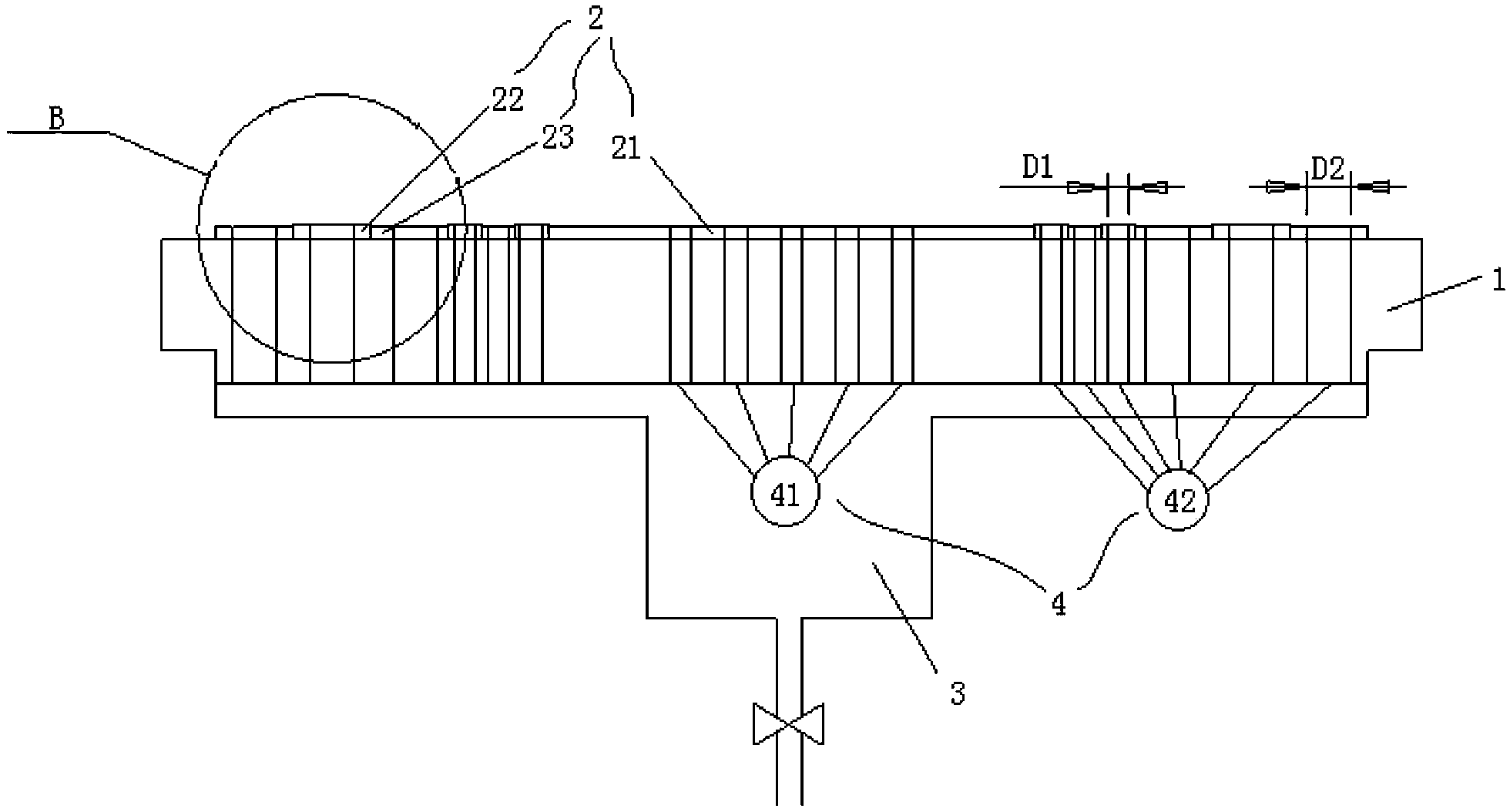

[0040] Such as figure 2 and 3 As shown, the vacuum chuck of the present invention includes a suction cup base 1, an adsorption layer 2 arranged on the upper part of the suction cup base 1, a vacuum chamber 3 arranged inside the suction cup base 1, and an adsorption layer arranged in arrays on the adsorption layer 2 and communicated with the vacuum chamber 3. Hole group 4, the adsorption layer 2 includes a central core 21 and an annular layer surrounding the core, the annular layer includes three annular elastic adsorption layers 22 and three annular rigid adsorption layers 23 arranged alternately, that is, From inside to outside are the first elastic adsorption layer 221 , the first rigid adsorption layer 231 , the second elastic adsorption layer 222 , the second rigid adsorption layer 232 , the third elastic adsorption layer 223 and the third rigid adsorption layer 233 .

[0041] The adsorption hole group 4 includes a core adsorption hole group 41 and an annular layer adsor...

Embodiment 2

[0047] Such as Figure 5 As shown, referring to Example 1, the difference is that the annular layer includes three annular elastic adsorption layers 22 interspersed with two annular rigid adsorption layers and two annular elastic adsorption layers, specifically from Inside-to-outside inner ring rigid adsorption layer 234, inner ring elastic adsorption layer 224, outer ring elastic adsorption layer 225 and outer ring elastic adsorption layer 235, the inner ring rigid adsorption layer 234 and the inner ring elastic adsorption layer 224 are provided with a small single hole 423, the adsorption holes set on the elastic adsorption layer 225 of the outer ring are porous 425, the sum of the hole areas of the porous holes 425 is greater than the small single hole 423, the large single hole 424 is set on the elastic adsorption layer 235 of the outer ring, the large single hole The pore area of 424 is not less than the sum of the pore areas of porous 425, and the pore diameter of a sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap