Whole grain coarse cereal power production method and whole grain coarse cereal power product

A manufacturing method and technology of multigrain powder, which are applied in the directions of food preparation, food ingredients, food forming, etc., can solve the problems of burden, difficult retention of nutrients, improper manufacturing methods, etc., so as to reduce the possibility of oxidative and qualitative changes of nutrients and the ability of self-excretion of wastes. Good, the effect of promoting peristalsis and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

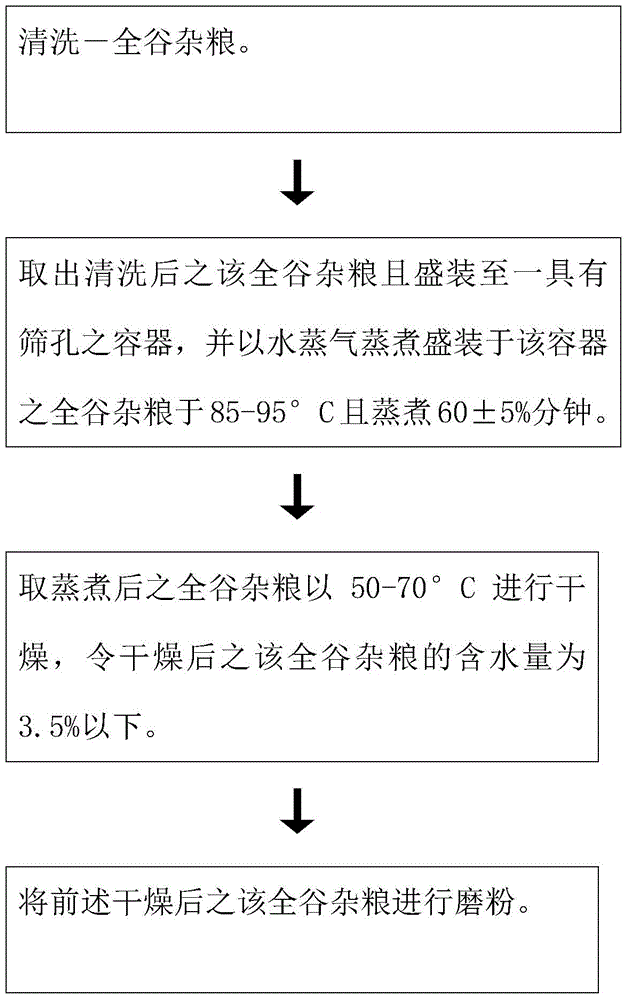

[0038] Please refer to shown in Fig. 1, a kind of whole grain miscellaneous grain flour manufacturing method and whole grain miscellaneous grain flour product of the present invention, wherein a kind of whole grain miscellaneous grain flour manufacturing method comprises the following steps:

[0039] 1. Wash a whole grain; in a preferred embodiment, the whole grain is washed with water, and the whole grain is washed with a high-pressure water column, and the whole grain is placed in a container with a sieve , and scrubbing the whole grain miscellaneous grains under a high-pressure water column to wash away the dust and the like of the whole grain miscellaneous grains.

[0040] 2. Put the washed whole grains into a container with a sieve, and steam the whole grains in the container for 60±5 minutes at 85-95°C.

[0041] 3. Drying the cooked whole grains at 50-70° C. so that the moisture content of the dried whole grains is below 3.5%.

[0042] 4. Grinding the dried whole grains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com