Clostridium beijerinckii with high stress resistance and application thereof

A Clostridium beijerinckii, inverse technology, applied in the field of genetic engineering and fermentation engineering, can solve the problems of complex inhibition mechanism and unclear inhibition mechanism, and achieve the goal of improving stress resistance, high efficiency stress resistance, and high butanol production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

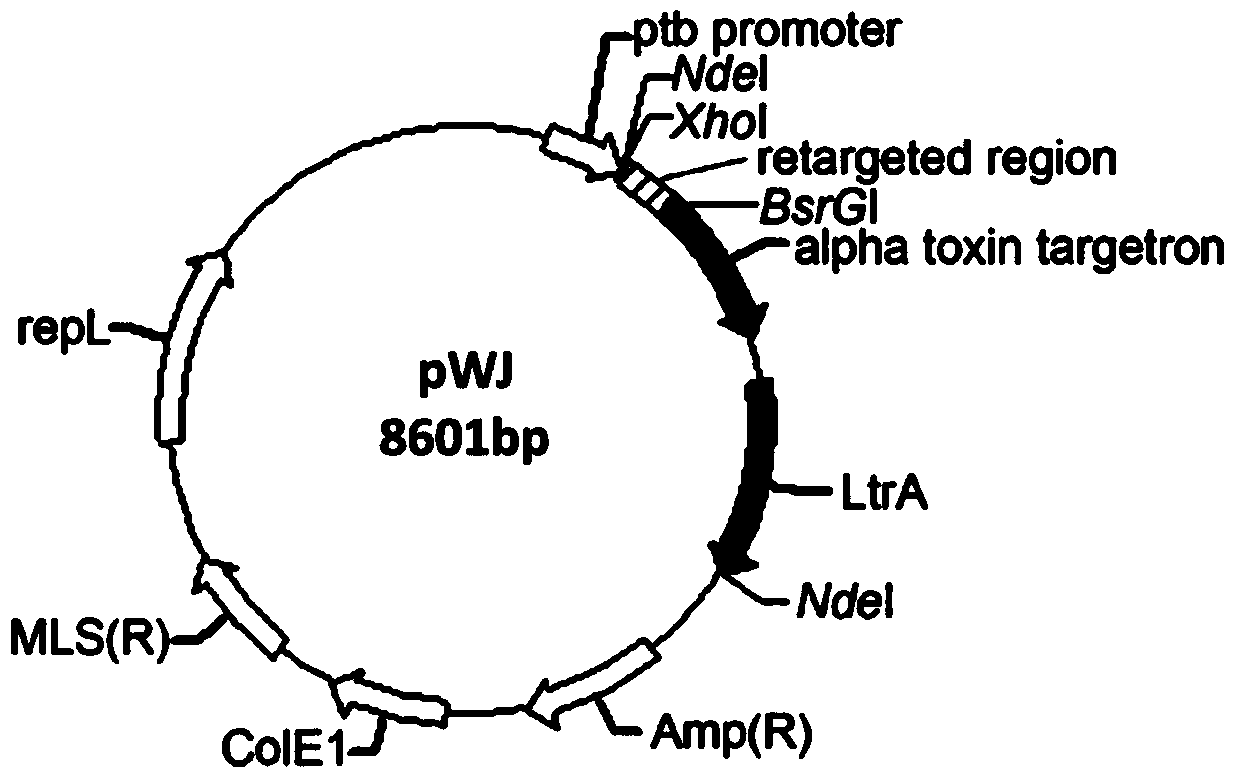

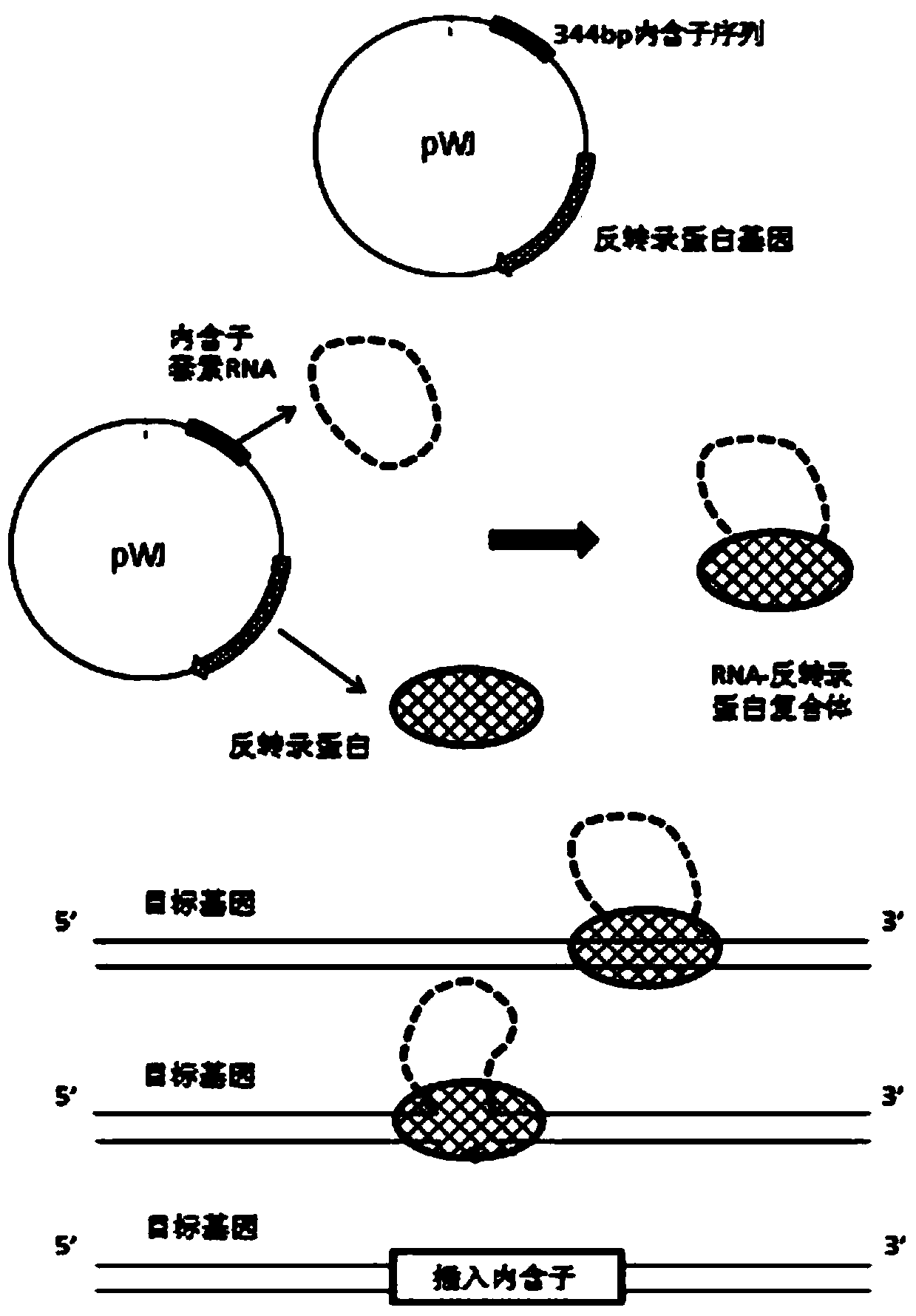

[0022] 1. Construction of Clostridium beijerinckii Cbei_3304 gene insertion inactivation mutant strain

[0023] The principle of constructing Clostridium beijerinckii Cbei_3304 gene insertion inactivation mutant strain is as follows figure 2 As shown, the specific construction process includes the following steps:

[0024] (1) Construction of Cbei_3304 insertion inactivation vector

[0025] 1) Design introns

[0026] According to the Cbei_3304 gene sequence of Clostridium beijerinckii included in the NCBI database (as shown in SEQ ID No: 1), the appropriate insertion gene site was designed with the help of software ( http: / / www.clostron.com ), select the insertion between bases 101-102, and generate an intron sequence, synthesize the intron sequence S-101 (its sequence is shown in SEQ ID NO: 2), and design the following primers.

[0027] Cloning primers:

[0028] pWJ-OSC-101-S: 5'-ggagtgtcgaggatc ctcgag ataattatccttacacttcgcc-3', its sequence is shown in SEQ ID NO:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com