Method for improving stress resistance of clostridium beijerinckii to 4-hydroxycinnamic acid

A technology of hydroxycinnamic acid and Clostridium beijerinckii is applied in the field of genetic engineering to achieve the effects of high stress resistance, improved stress resistance and high-efficiency stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

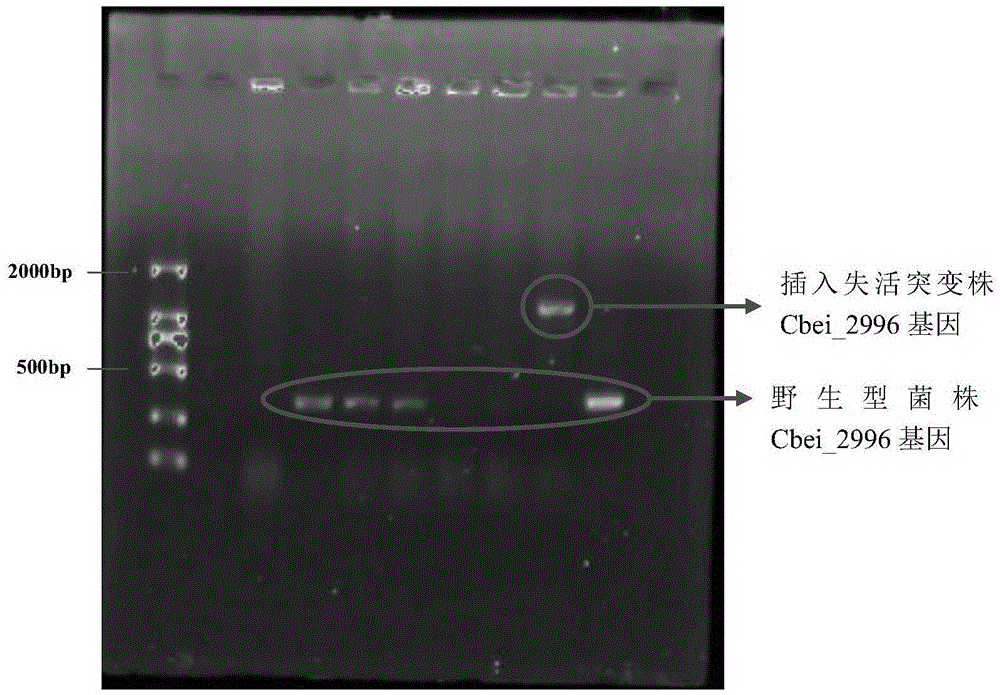

[0046] Embodiment 1: Construction method of Clostridium beijerinckii Cbei_2996 gene inactivation mutant

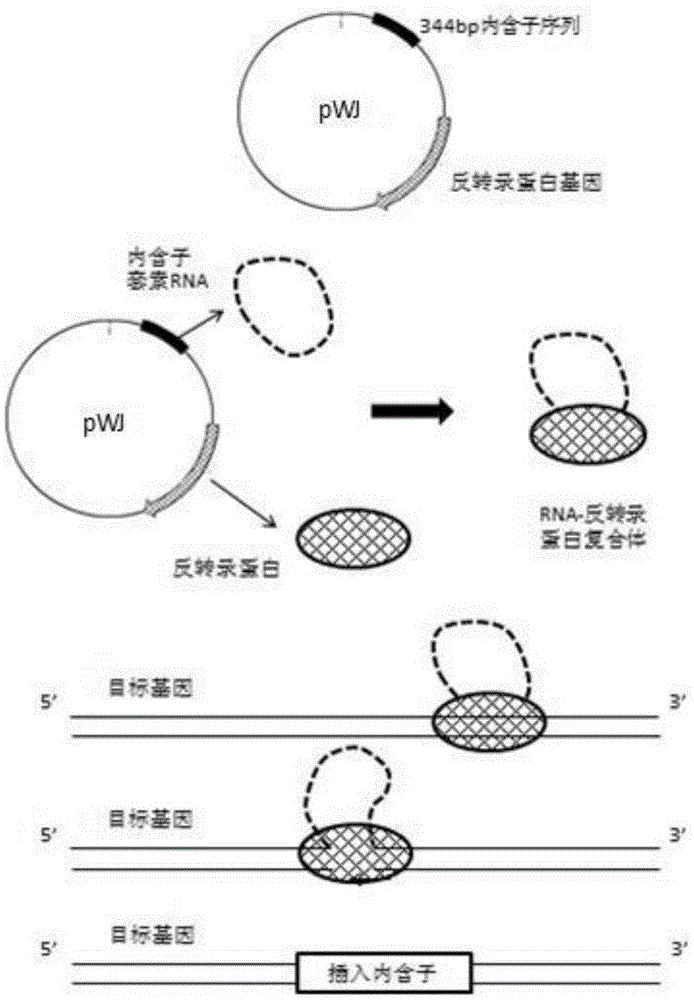

[0047] (1) Design introns:

[0048] According to the Cbei_2996 gene sequence of Clostridium beijerinckii included in the NCBI database (as shown in SEQ ID No: 1), that is, the base sequence (nuoA) encoding coenzyme Q oxidoreductase subunit A, the appropriate insertion gene site was designed with the help of software ( http: / / www.clostron.com), through the previous experimental screening and verification, it was selected to be inserted between the 62nd and 63rd bases of the Cbei_2996 gene sequence, and an intron sequence was generated, and the synthetic intron was S- 62, the sequence of which is shown in SEQ ID NO:2.

[0049] (2) Construction of Cbei_2996 insertion inactivation vector:

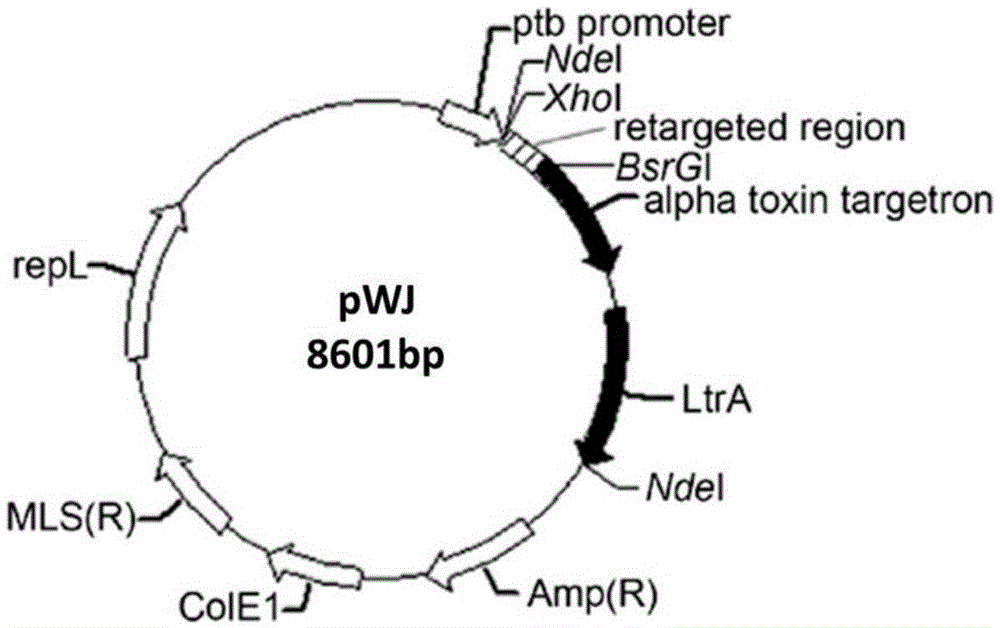

[0050]Use XhoI and BsrGI to double-enzyme-cut the vector pWJ (provided by Yang Sheng, Shanghai Academy of Biological Sciences, its sequence is shown in SEQ ID NO: 5, and the plasmid map o...

Embodiment 2

[0061] Embodiment 2: Passage stability of the recombinant bacterium of Cbei_2996 gene inactivation

[0062] The culture medium formula described in the present embodiment:

[0063] Plate medium: yeast powder 3g / L, peptone 5g / L, soluble starch 10g / L, ammonium acetate 2g / L, sodium chloride 3g / L, magnesium sulfate heptahydrate 3g / L, potassium dihydrogen phosphate 1g / L, Dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, agar 15g / L, the rest is water, pH6.

[0064] Seed medium: yeast powder 3g / L, peptone 5g / L, soluble starch 10g / L, ammonium acetate 2g / L, sodium chloride 3g / L, magnesium sulfate heptahydrate 3g / L, potassium dihydrogen phosphate 1g / L, Dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, the rest is water, pH6.

[0065] Fermentation medium: glucose 30g / L, ammonium acetate 2.2g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, sodium chloride 0.01g / L, magnesium sulfate heptahydrate 0.2g / L , fe...

Embodiment 3

[0071] Example 3: Investigation of the stress resistance of recombinant bacteria and starting strains to 4-hydroxycinnamic acid

[0072] Plate medium: yeast powder 3g / L, peptone 5g / L, soluble starch 10g / L, ammonium acetate 2g / L, sodium chloride 3g / L, magnesium sulfate heptahydrate 3g / L, potassium dihydrogen phosphate 1g / L, Dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, agar 15g / L, the rest is water, pH6.

[0073] Seed medium: yeast powder 3g / L, peptone 5g / L, soluble starch 10g / L, ammonium acetate 2g / L, sodium chloride 3g / L, magnesium sulfate heptahydrate 3g / L, potassium dihydrogen phosphate 1g / L, Dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, the rest is water, pH6.

[0074] Fermentation medium: glucose 30g / L, ammonium acetate 2.2g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, sodium chloride 0.01g / L, magnesium sulfate heptahydrate 0.2g / L , ferrous sulfate heptahydrate 0.01g / L, manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com