Device and method for exhaust gas recirculation of an internal combustion engine and corresponding internal combustion engine

A technology of exhaust gas recirculation and internal combustion engine, which is applied in the direction of exhaust gas recirculation, mechanical equipment, internal combustion piston engine, etc., can solve the problems of efficiency loss and high cost, and achieve the effect of reducing efficiency and simple detection of exhaust gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

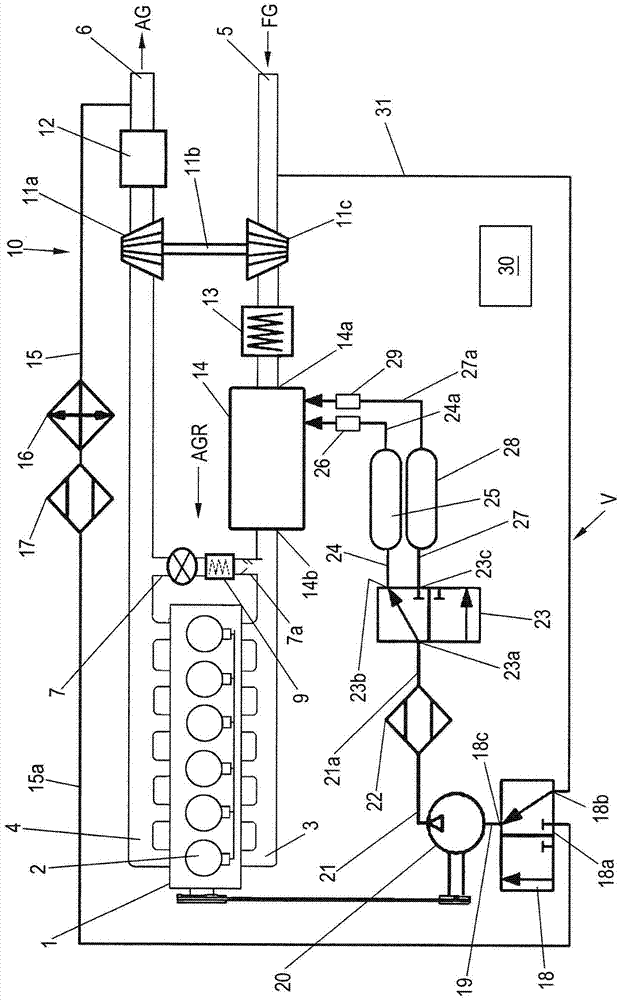

[0041] figure 1 A schematic diagram of an internal combustion engine 1 with an exhaust gas turbocharger 10 and a device V according to the invention for exhaust gas recirculation is shown.

[0042] In this embodiment, the internal combustion engine 1 is a diesel engine with six cylinders 2 , an intake line 3 and an exhaust line 4 . The exhaust gas turbocharger 10 has an exhaust gas turbine 11a which is coupled via a shaft 11b to a compressor 11c. The intake line 3 is connected to the compressor 11 c of the exhaust gas turbocharger 10 via a gas supply device 14 . In this case, a charge air cooler 13 is arranged between the gas delivery device 14 and the compressor 11 c. The compressor 11c of the exhaust gas turbocharger 10 is connected to the air intake 5 for the fresh gas FG. The term fresh air here also refers to fresh air from the atmosphere. An air filter (not shown in the figure) can also be inserted in this line.

[0043] For the exhaust gas AG of the internal combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com