Thermal pulse sap flow or water flux density measuring apparatus capable of correcting space and measuring method

A measurement device and flux measurement technology, applied in the field of measurement, can solve problems such as temperature probe or heating probe bending, deviation, temperature probe deformation and deformation, and achieve the effects of low cost, fast and accurate measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

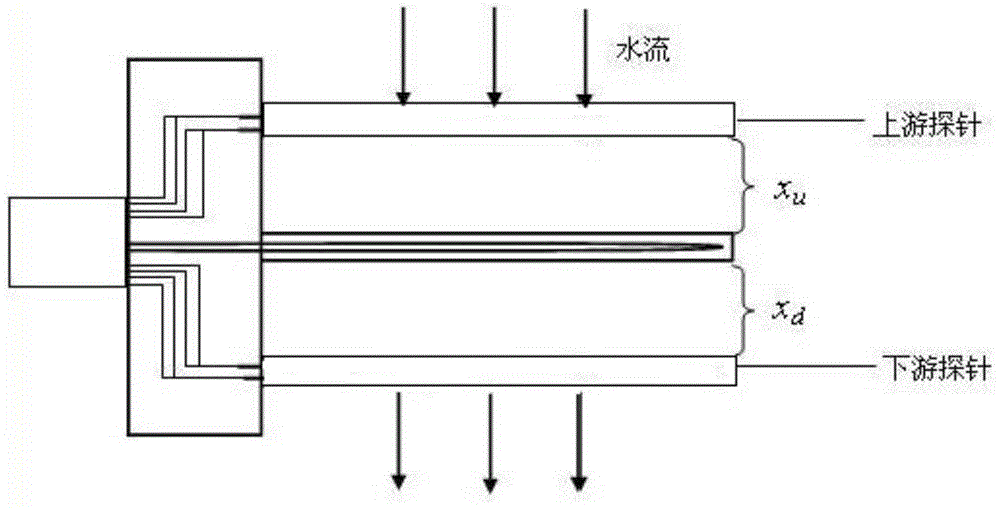

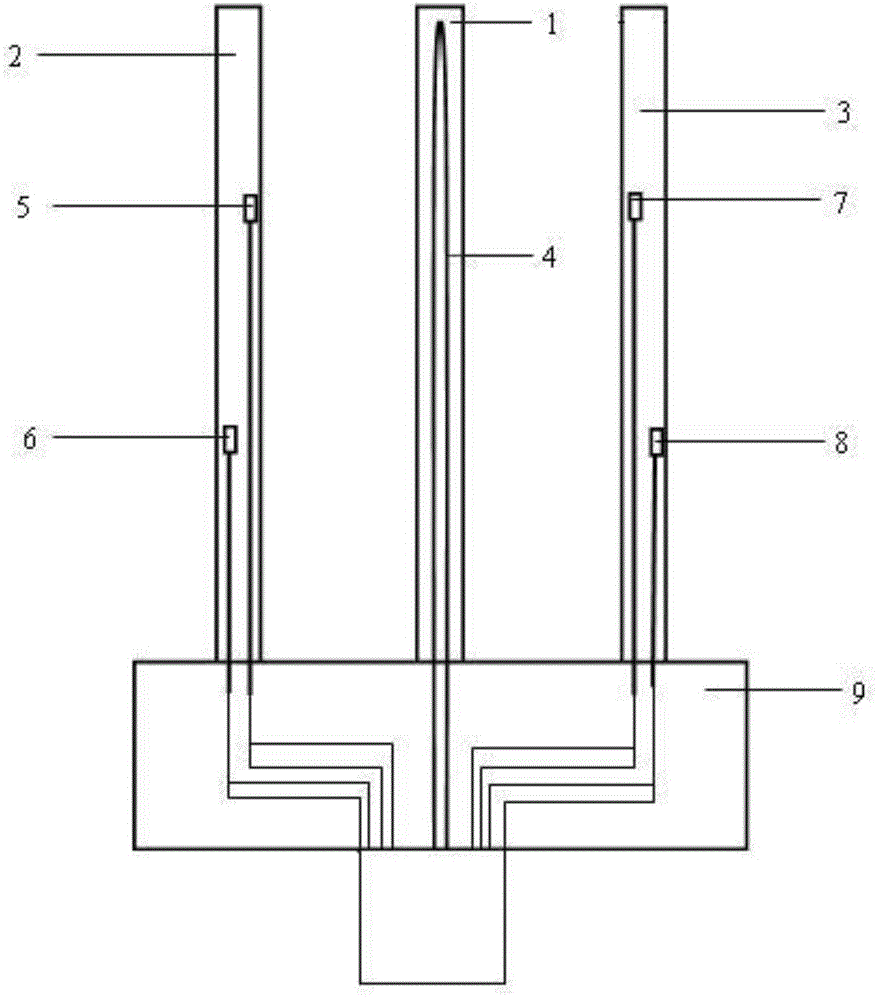

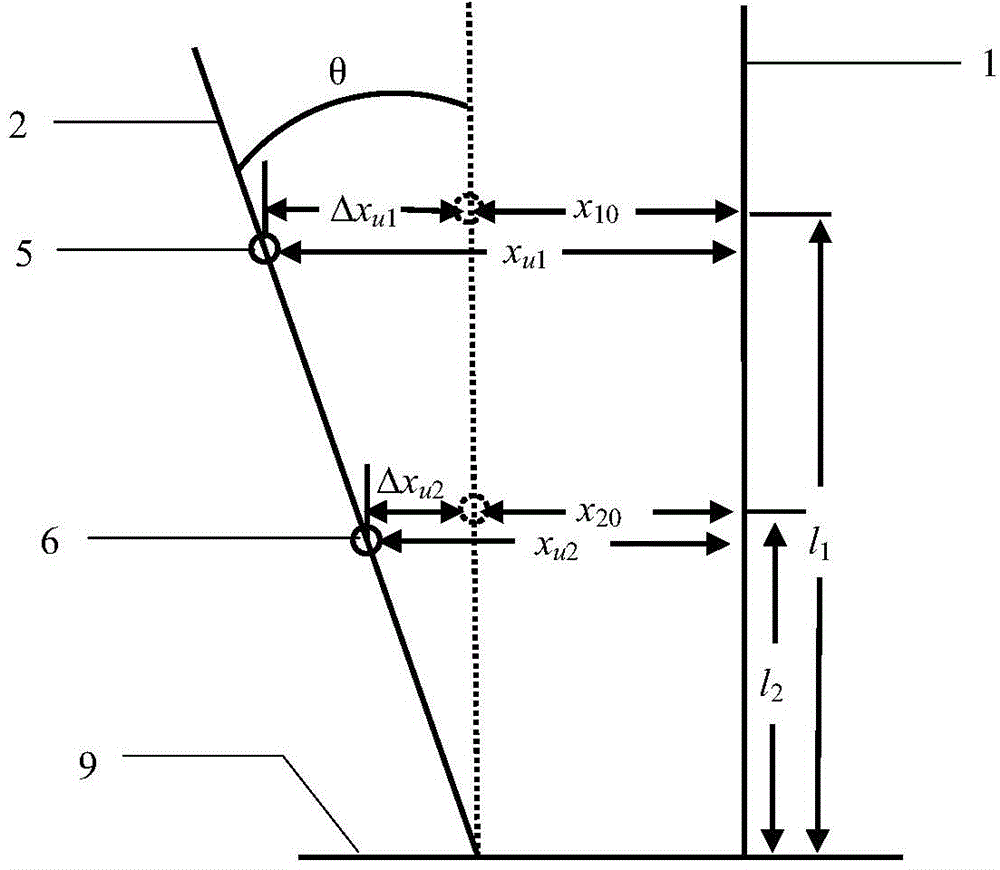

[0103] figure 2 It is a structural schematic diagram of a thermal pulse sap flow or water flow measurement device capable of correcting pitch in a preferred embodiment of the present invention. In this embodiment, the temperature probe adopts two methods, and the measuring device includes a heating probe 1 and a temperature probe 2, 3 fixed on the base 9, and the heating probe 1 and the temperature probe 2, 3 are all made of hollow stainless steel tubes become. There is a heating wire 4 of nickel-chromium alloy material inside the heating probe 1 . Wherein the ratio of the length of the heating probe 1 to the inner diameter is greater than 25, the ratio of the length of the temperature probe 2 to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com