Multistage resistive random access memory and manufacturing method thereof

A technology of resistive variable memory and resistive variable layer, applied in static memory, digital memory information, information storage, etc., to achieve the effects of increasing stability, protecting the bottom electrode, and reducing dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It should be noted that the present invention is not limited to the embodiments.

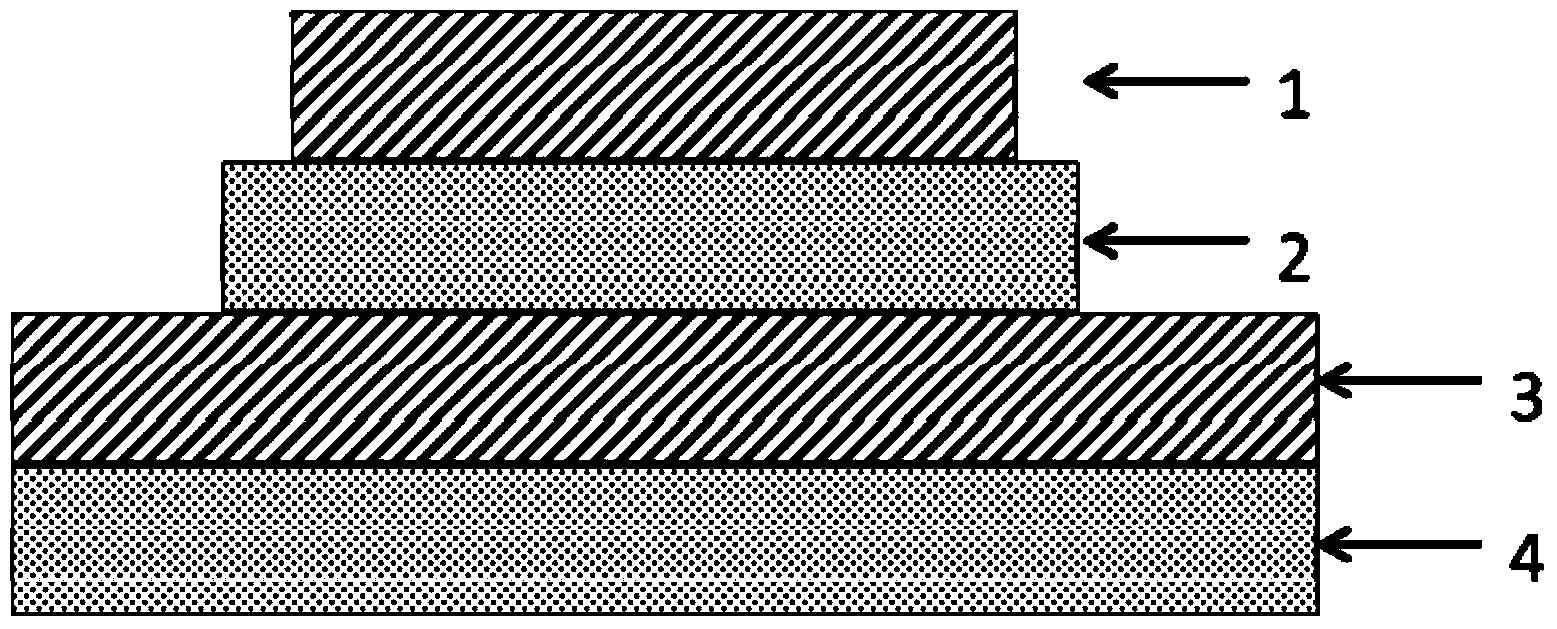

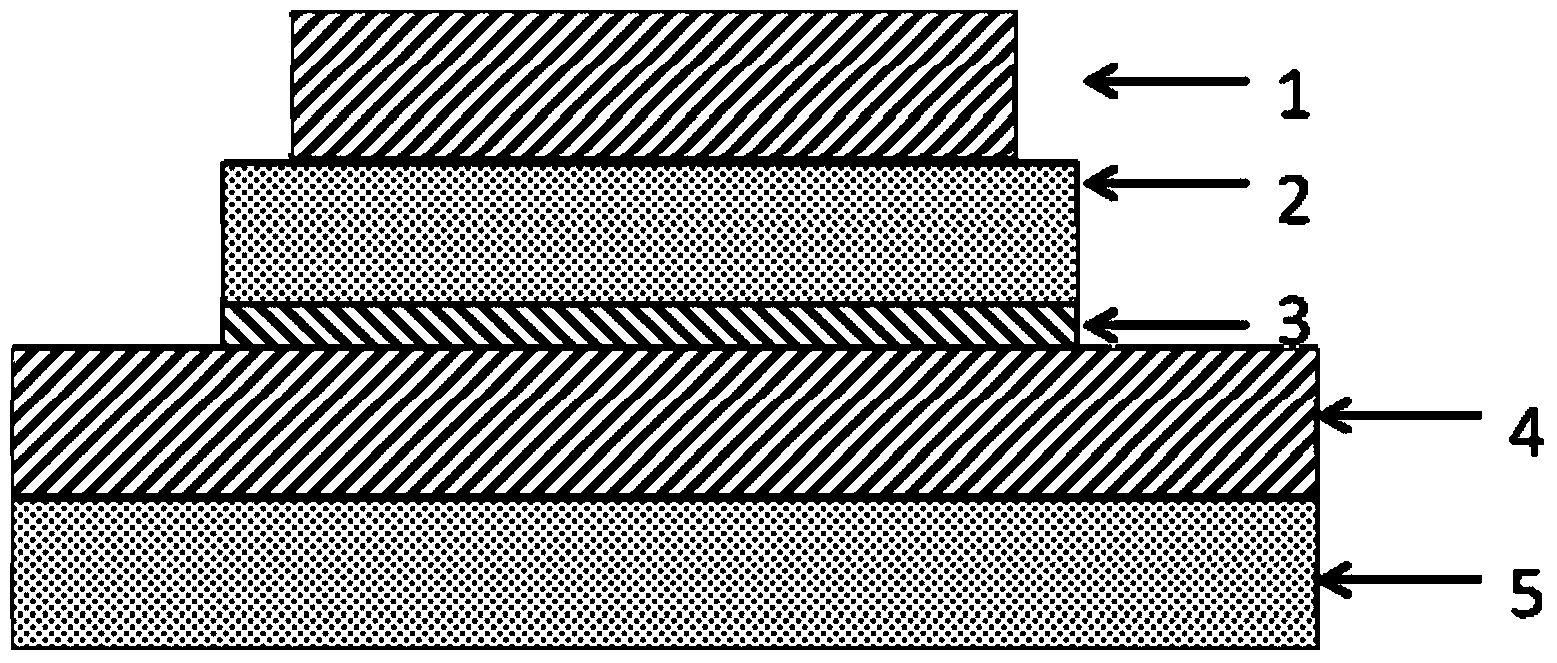

[0024] A multi-level resistive variable memory unit, comprising a substrate, a bottom electrode, a resistive variable layer, and a top electrode sequentially arranged from bottom to top; it is characterized in that an isolation layer is also arranged between the bottom electrode and the resistive variable layer. Its structure is as figure 2 shown.

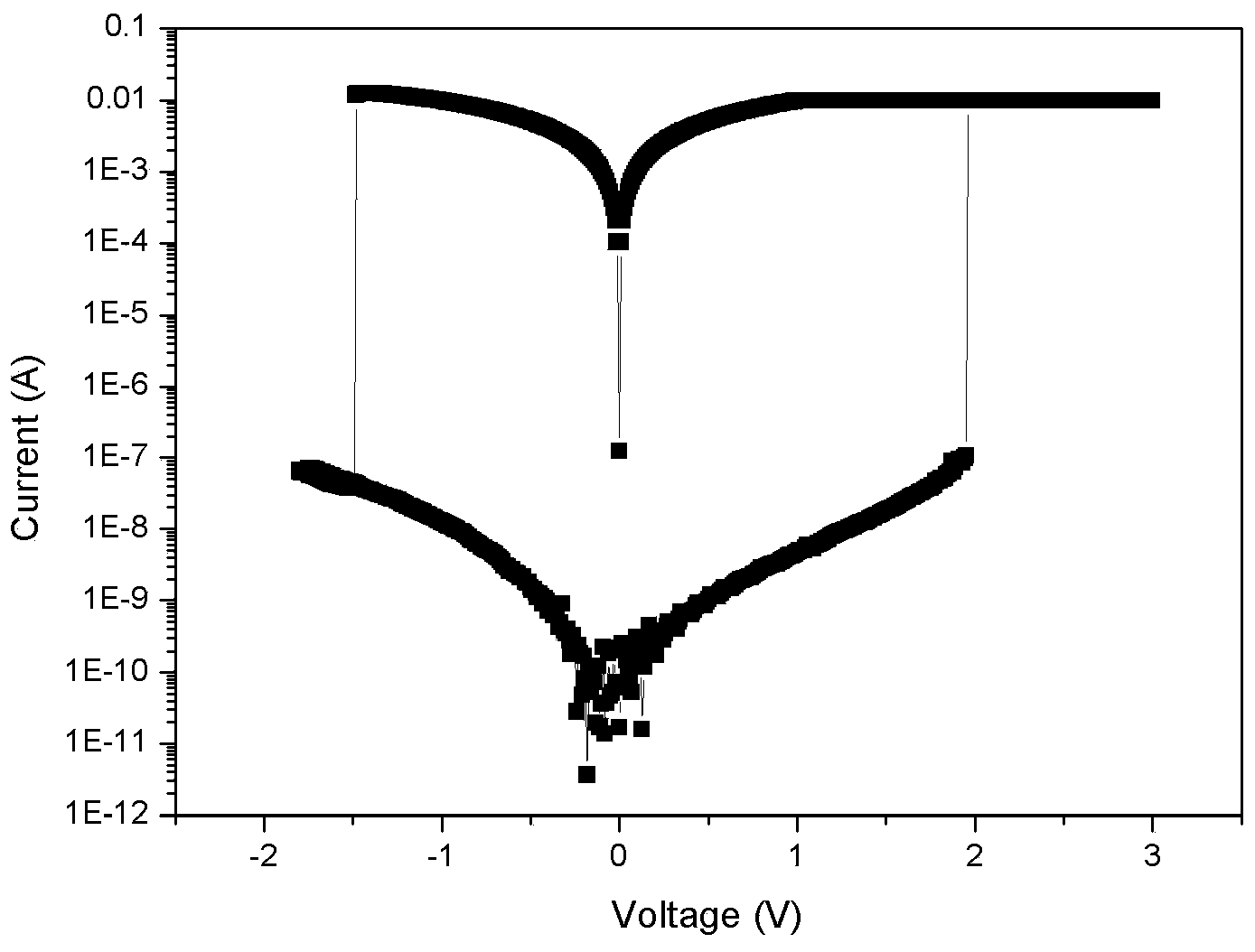

[0025] In this embodiment, the multi-level resistive variable memory unit is square, and its long side and short side are both 200 microns, the material of the isolation layer is Ta, and the thickness is 2nm; the material of the resistive layer is NiO, and the thickness is 55nm; the top electrode It is a Cu film with a thickness of 150 nm and a long side and a short side of 100 micrometers. It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com