Composite field membrane separation experimental facility suitable for general flat sheet membrane element

An experimental device and membrane separation technology, applied in the field of membrane separation, can solve the problems of inconvenient use and poor versatility, and achieve the effect of good versatility and flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

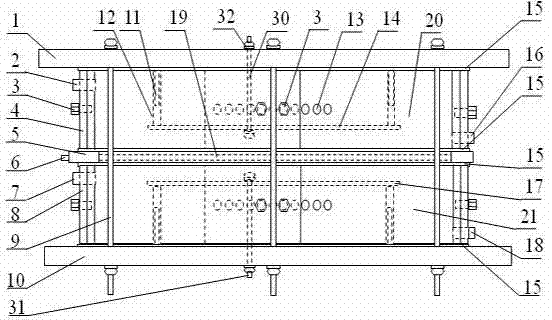

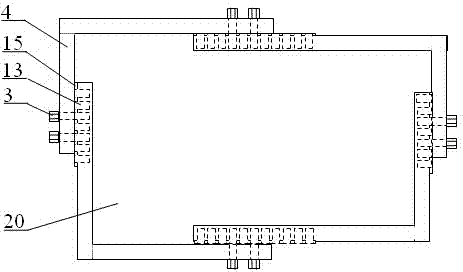

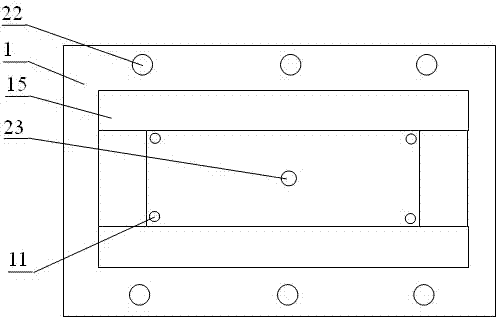

[0022] See attached figure 1 and Figure 6 , the composite field membrane separation experiment device suitable for general-purpose flat membrane elements of the present invention includes a body structure and an ultrasonic transducer 26 externally connected to the body structure, an ultrasonic generator 28, and a high-voltage AC pulse power supply 29 . The body structure is a symmetrical structure up and down, with a membrane element 5 in the middle, and three independent closed cavities are formed by the upper splint 1 and the lower splint 10, the upper cavity wall 4 and the lower cavity wall 8, and the membrane element 5 in the middle. The three independent closed cavities are respectively the feeding liquid cavity 20 , the feeding liquid cavity 21 and the filtrate cavity 19 in the membrane element 5 . The feeding liquid cavity 20 is surrounded by the upper splint 1, the upper cavity wall 4 and the membrane element 5, the feeding liquid cavity 21 is surrounded by the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com