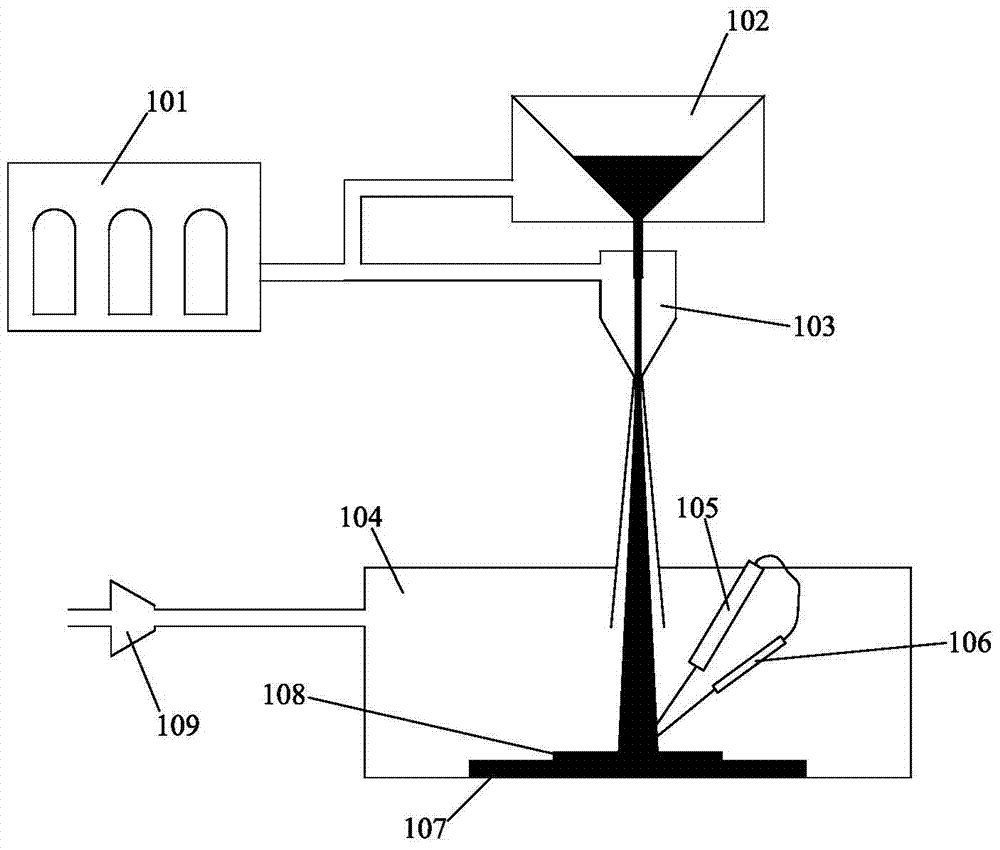

Laser-assisted cold spray coating method and nozzle apparatus

A laser-assisted, nozzle device technology, applied in the direction of spraying devices, liquid spraying devices, devices for coating liquid on the surface, etc., can solve the problems of large gas consumption, achieve uniform preheating, avoid clogging, and eliminate gas heating devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

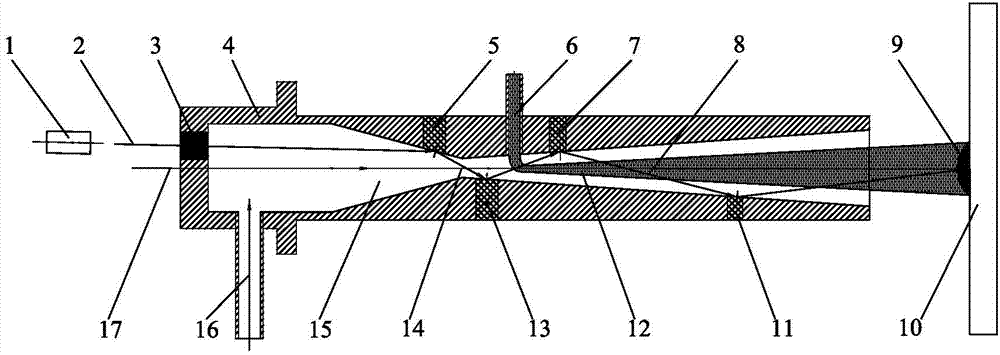

[0021] like figure 2 The shown laser-assisted cold spraying nozzle device includes a nozzle 4, one side of the nozzle throat 14 is a nozzle constriction section 15, the other side of the nozzle 4 throat 14 is a nozzle expansion section 12, and the nozzle 4 is in the nozzle constriction section One side of 15 is provided with a high-pressure gas inlet 16 and a light-transmitting window 3 for the laser beam 2 to enter. The light-transmitting window 3 is set away from the nozzle axis 17. The nozzle 4 is provided with a reflector A5 on the nozzle contraction section 15. One side of section 12 is provided with powder inlet 6, reflector B7, reflector C11 and reflector D13, and the laser beam 2 entering from light-transmitting window 3 passes through reflector A5, reflector D13, reflector B7 and After being reflected by the mirror C11, it shoots out from the nozzle expansion section 12, and the powder inlet 6 is located between the mirror D13 and the mirror B7. The high-pressure ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com