Superconductor cold pressing connecting method

A bonding method and superconductor technology, applied in conductors, welding equipment, non-electric welding equipment, etc., can solve the problems of low joint strength of high-temperature superconducting materials and loss of superconducting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

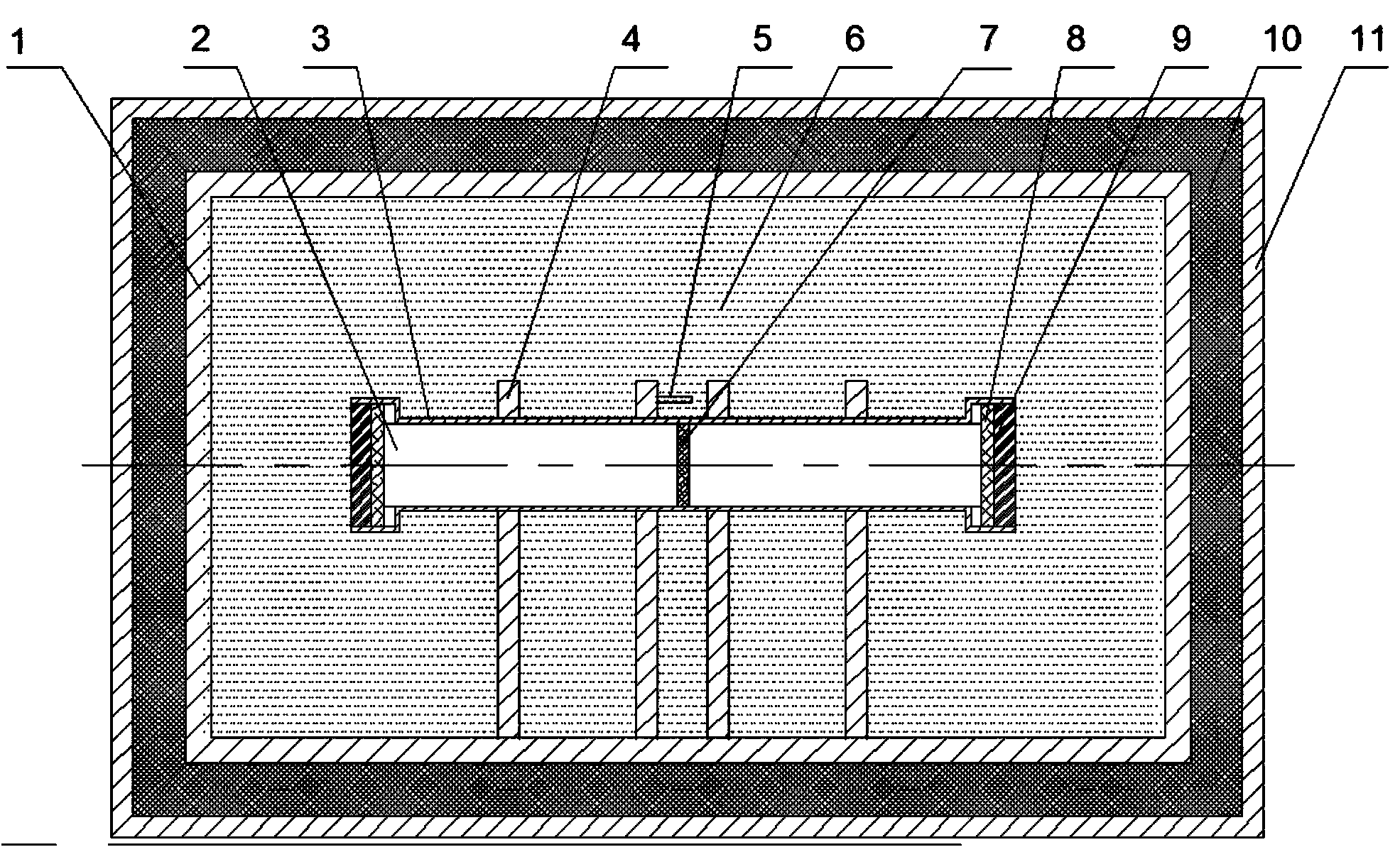

[0012] Specific implementation mode one: as figure 1 As shown, a superconductor cold-compression bonding method in this embodiment is carried out according to the following steps:

[0013] 1. Pretreatment: grinding the end surfaces of two rod-shaped superconductors flat, and then polishing them to obtain the processed first rod-shaped superconductor 2, the second rod-shaped superconductor 12 and superconductor powder;

[0014] 2. The superconductor powder obtained in step 1 is made into a cake shape to obtain a cake-shaped superconductor 7;

[0015] 3. The first round bar-shaped superconductor 2 and the second round bar-shaped superconductor 12 processed in step 1 are horizontally arranged on the support 4 with the end faces facing each other, and the two end faces of the first round bar-shaped superconductor 2 and the second round bar-shaped superconductor 12 are opposite to each other. The disc-shaped superconductor 7 that step 2 obtains is arranged in parallel between them...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the copper oxide high temperature superconductor is Bi 2 Sr 2 Ca 2 Cu 3 o 8 + X superconductor. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the iron-based high-temperature superconductor is SmFeAsO 1-x f x superconductor. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com