A kind of production technology of fep colored particle

A production process and colored particle technology, which is applied in the field of FEP colored particle production process, can solve problems such as die casting, toner decomposition, and difficult control of parameters, so as to improve the concentration of sub-mass, reduce die casting, The effect of short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

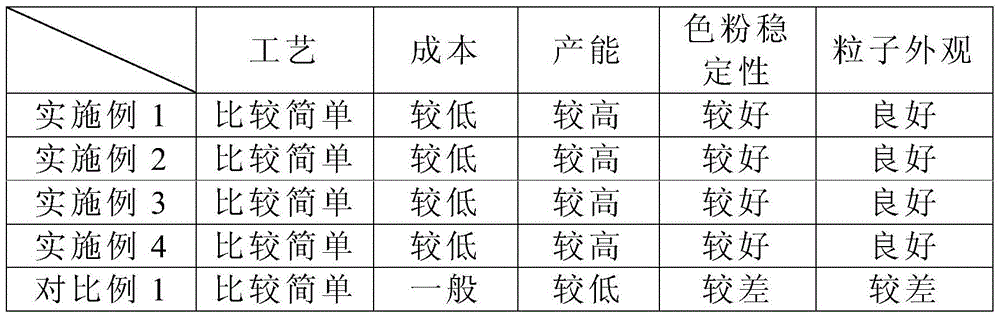

Examples

Embodiment 1

[0020] Set the temperature of the twin-screw extruder to 420°C, the temperature of the single-screw extruder to 420°C, and the speed of the main engine to 200r / min. Then the FEP pellets with a particle size of 100 meshes were screened as the main feed, and were put into the feeding hopper of the twin-screw extruder. The temperature of the feeder was set at 120°C, and the feeder was fed into the twin-screw extruder. The twin-screw extruder absorbs the toner through side feeding, and the FEP pellets are mixed with the toner and then extruded through the twin-screw extruder. The outlet of the twin-screw extruder is provided with a filter block. The single-screw extruder no longer mixes materials, and directly feeds into the single-screw extruder through the open free gravity of the twin-screw extruder, directly builds up a pressure of 8MPa, and then passes through the filter screen to the die for drawing. Finally, FEP colored particles are obtained through water cooling, air dryi...

Embodiment 2

[0022] Set the temperature of the twin-screw extruder to 430° C., the temperature of the single-screw extruder to 430° C., and the speed of the main engine to be 220 r / min. Then the FEP pellets with a particle size of 200 meshes were screened as the main feed, and were put into the feeding hopper of the twin-screw extruder. The temperature of the feeder was set at 130°C, and the feeder was fed into the twin-screw extruder. The twin-screw extruder absorbs the toner through side feeding, and the FEP pellets are mixed with the toner and then extruded through the twin-screw extruder. The outlet of the twin-screw extruder is provided with a filter block. The single-screw extruder no longer mixes materials, and directly feeds into the single-screw extruder through the open free gravity of the twin-screw extruder, directly builds up a pressure of 10MPa, and then passes through the filter screen to the die for drawing. Finally, FEP colored particles are obtained through water cooling,...

Embodiment 3

[0024] Set the temperature of the twin-screw extruder to 440°C, the temperature of the single-screw extruder to 440°C, and the speed of the main engine to 230r / min. Then the FEP pellets with a particle size of 300 meshes were screened as the main feed, and were put into the feeding hopper of the twin-screw extruder. The temperature of the feeder was set at 140°C, and the feeder was fed into the twin-screw extruder. The twin-screw extruder absorbs the toner through side feeding, and the FEP pellets are mixed with the toner and then extruded through the twin-screw extruder. The outlet of the twin-screw extruder is provided with a filter block. The single-screw extruder no longer mixes materials, and directly feeds into the single-screw extruder through the open free gravity of the twin-screw extruder, directly builds up a pressure of 12MPa, and then passes through the filter screen to the die for drawing. Finally, FEP colored particles are obtained through water cooling, air dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com