Concentrated water recycling method and filtering system with concentrated water recycling function

A filtration system and concentrated water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as inconvenient operation, limited flushing water, loss, etc., to achieve High degree of automation control, simple system structure, and the effect of eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The concentrated water reuse method of the present embodiment is as follows:

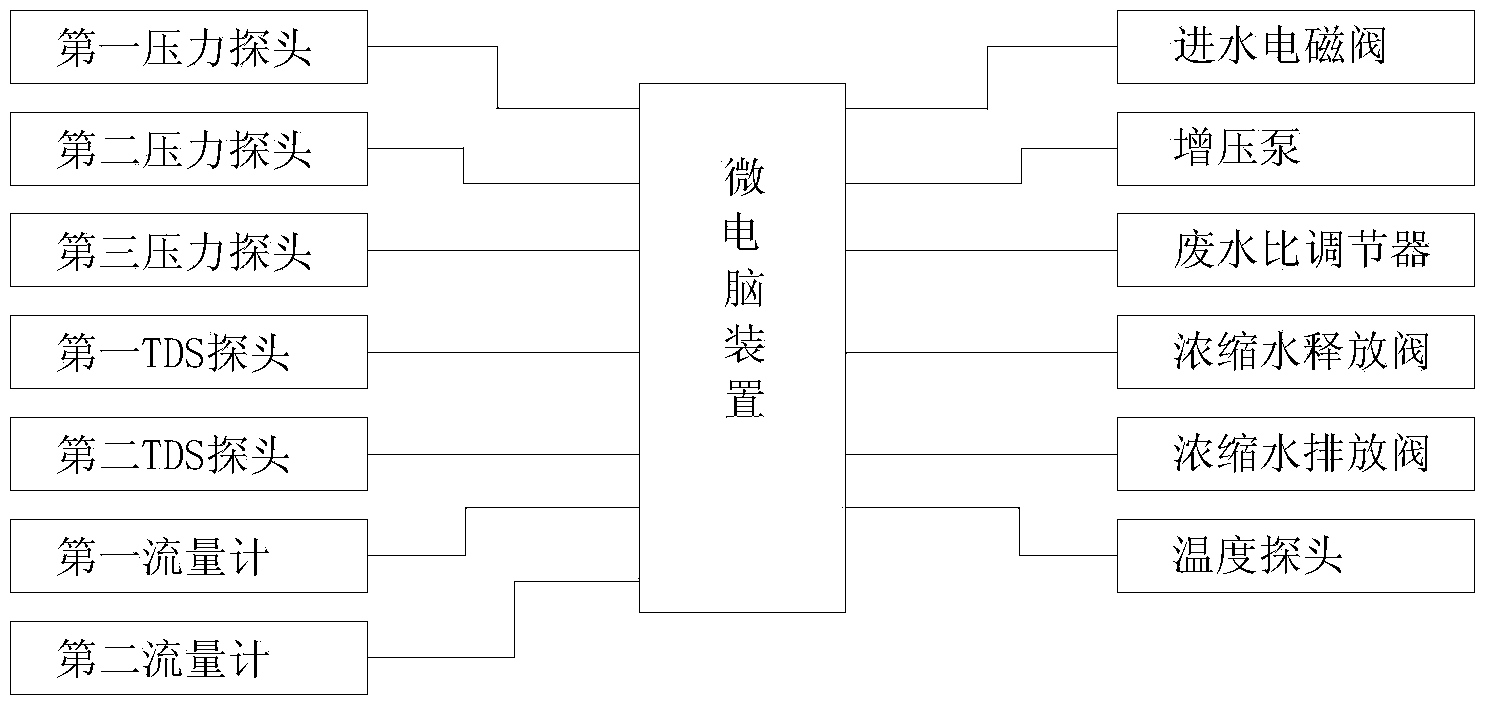

[0040] Collect the concentrated water obtained by reverse osmosis filtration into the concentrated water storage tank. If the current raw water pressure value measured by the first pressure probe is P1, the unit is MPA; the raw water TDS value measured by the first TDS probe is N1 , the unit is PPM; the concentrated water pressure value measured by the second pressure probe is P2, and the unit is MPA; the concentrated water TDS value measured by the second TDS probe is N2, and the unit is PPM. Then when the user opens the mixer tap, the microcomputer device will retrieve the corresponding control parameters from the database according to the above data, and control the concentrated water release valve to perform the following actions: the opening time is T, and the unit is second. In this way, the released amount of concentrated water is controlled to ensure that the concentrated water is con...

Embodiment 2

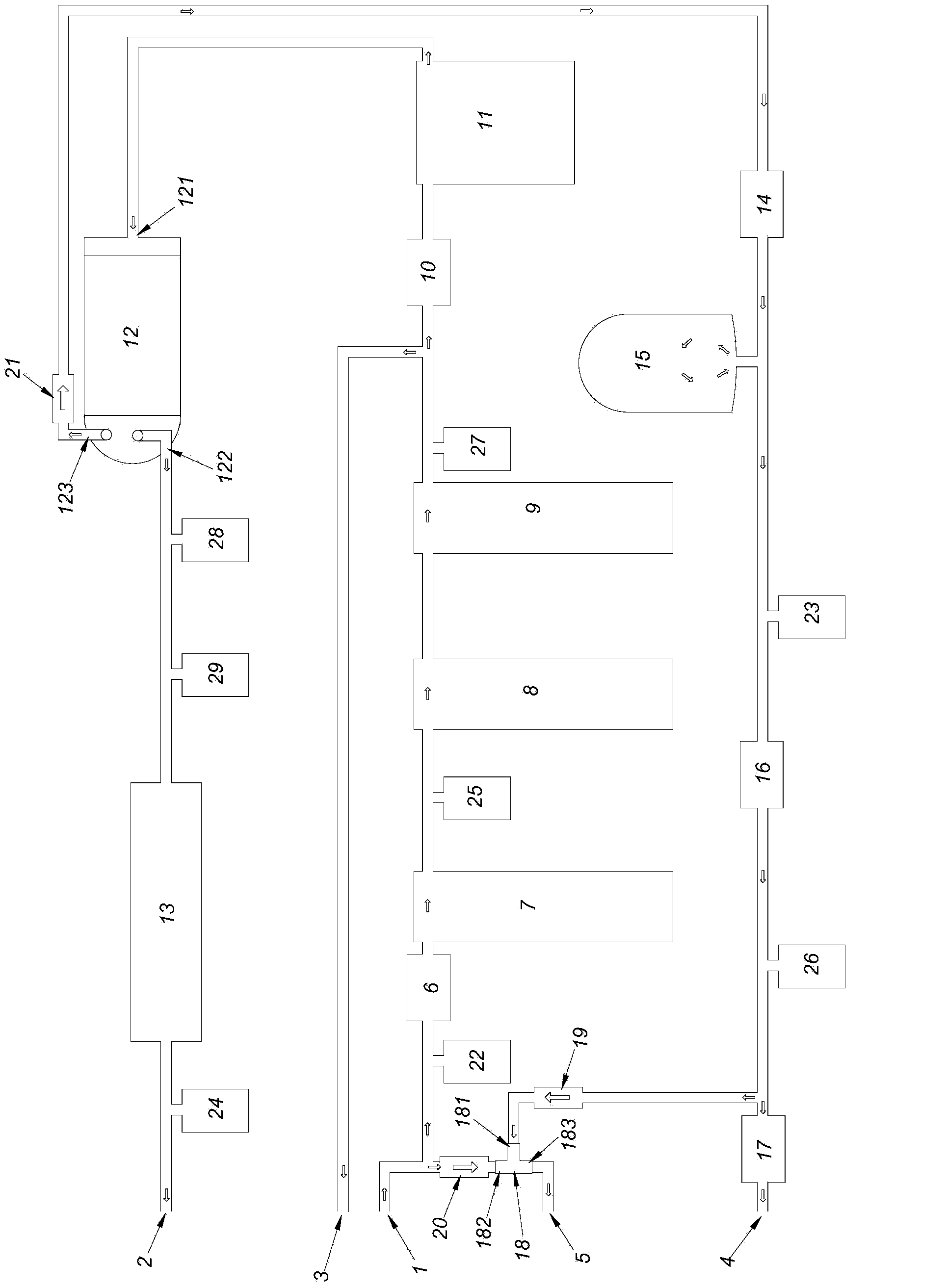

[0042] Such as figure 1 As shown, the filtration system with concentrated water reuse in this embodiment includes: raw water inlet 1, pure water outlet 2, purified water outlet 3, concentrated water outlet 4 and mixed water outlet 5; and decompression Valve 6, first stage filter 7, second stage filter 8, third stage filter 9, water inlet solenoid valve 10, booster pump 11, reverse osmosis filter 12, fifth stage filter 13, waste water ratio Regulator 14, concentrated water storage tank 15, concentrated water release valve 16, concentrated water discharge valve 17, tee piece 18, first one-way valve 19, second one-way valve 20, third one-way valve 21; and the first A pressure probe 22, a second pressure probe 23, a third pressure probe 24, a first TDS probe 25, a second TDS probe 26, a first flow meter 27, a second flow meter 28, a temperature probe 29 and a microcomputer device. The first-stage filter 7, the second-stage filter 8 and the third-stage filter 9 of this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com