Method for preparing down feather with self-cleaning function

A self-cleaning, down-feather technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems that affect the comfort of down products, difficult to eradicate, down mildew, etc., and achieve the effect of not reducing the photodegradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

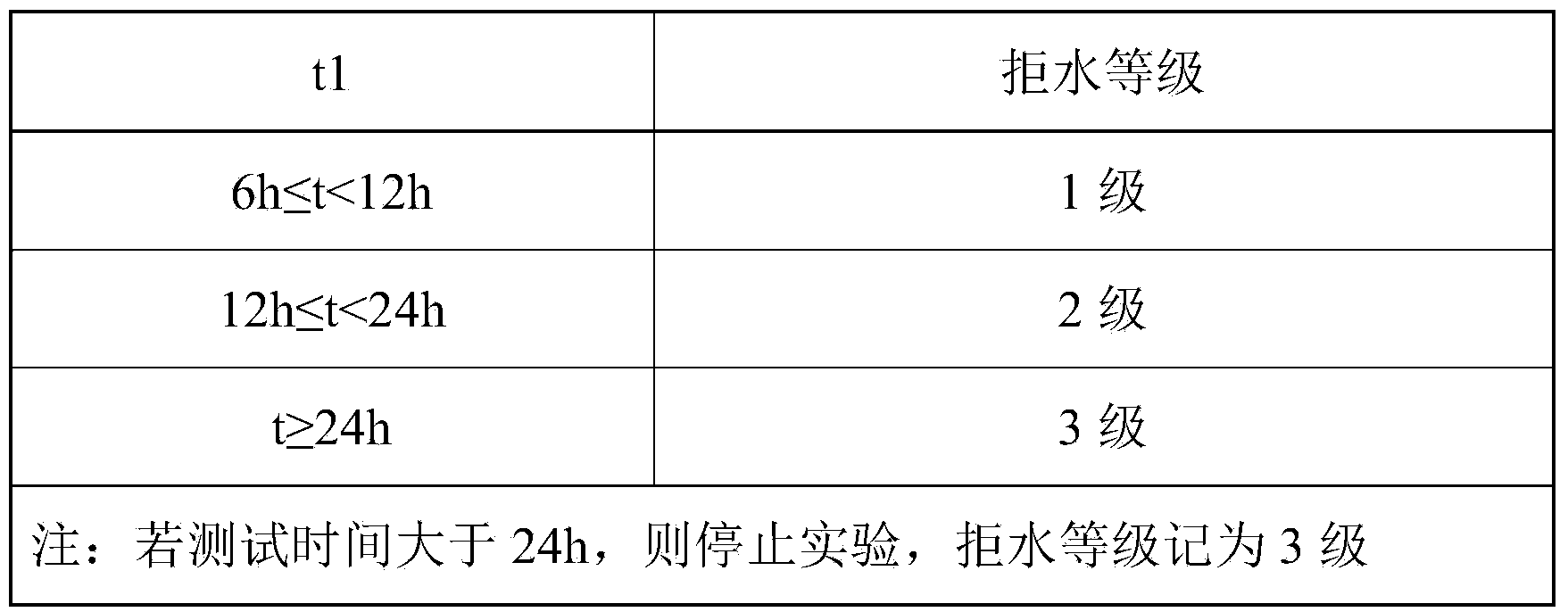

Examples

Embodiment 1

[0022] A preparation method for self-cleaning functional down, comprising the following steps:

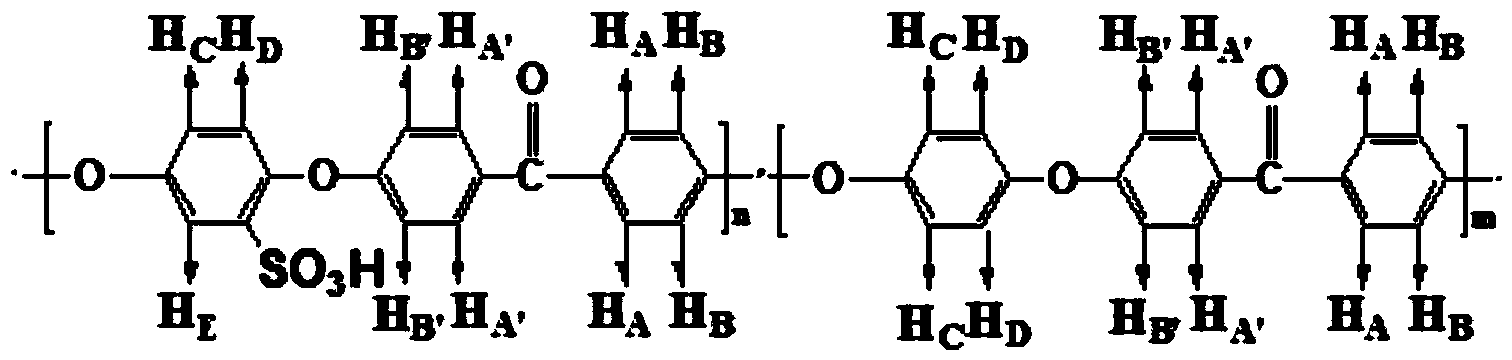

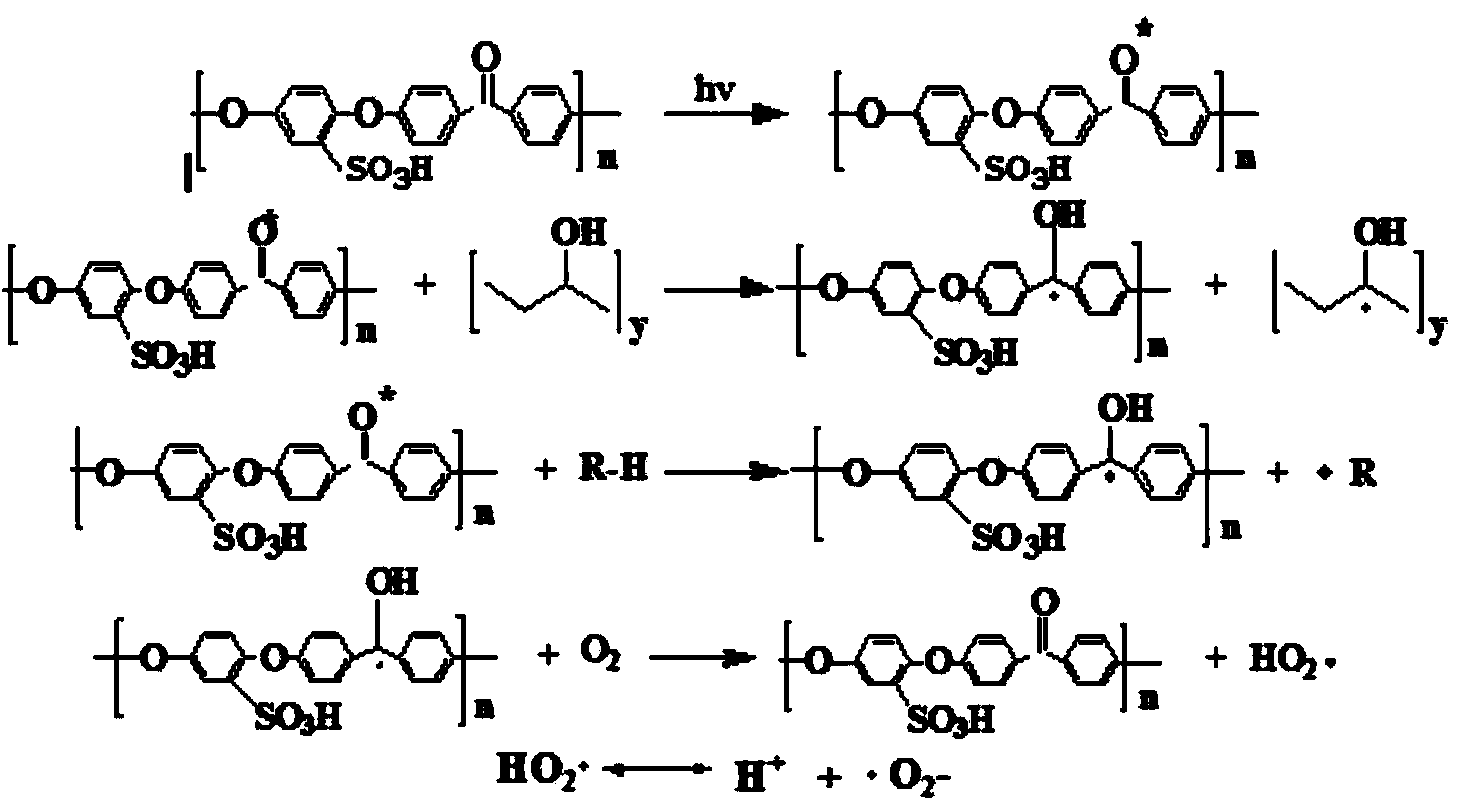

[0023] (1) Preparation of photodegradation system: Weigh 50g of sulfonated polyether ether ketone and dissolve it in 500ml of water, heat it to 50°C in an ultrasonic environment to accelerate dissolution; weigh 30g of silk fibroin polypeptide powder (particle size 50μm, purity greater than 95%) Dissolve in 500ml of cold water and fully swell for 3 hours, then heat to 70°C to dissolve. Under the condition of 70°C, the two solutions were fully stirred and mixed, and HCl was added to control the pH to 5.5 to prepare a photodegradation system;

[0024] The preparation method of sulfonated polyether ether ketone is: dry polyether ether ketone (Victrex, 450G) pellets at 100°C under vacuum for 6h, then weigh 4g and dissolve in 200mL concentrated sulfuric acid (98%) at 50°C , the rotation speed is 400r / min, stir vigorously for 15min, pour the reaction solution into 8 times the volume of i...

Embodiment 2

[0028] A preparation method for self-cleaning functional down, comprising the following steps:

[0029] (1) Preparation of photodegradation system: weigh 50g of sulfonated polyetheretherketone and dissolve it in 500ml of water, heat it to 50°C in an ultrasonic environment to accelerate dissolution; weigh 20g of silk fibroin polypeptide powder (particle size 50μm, purity greater than 95%) Dissolve in 500ml of cold water and fully swell for 3 hours, then heat to 80°C to dissolve. At 80°C, the two solutions were fully stirred and mixed, and HCl was added to control the pH to 5.5 to prepare a photodegradation system;

[0030] The preparation method of sulfonated polyether ether ketone is as follows: dry polyether ether ketone (Victrex, 450G) pellets at 100°C under vacuum for 6h, then weigh 4.5g and dissolve them in 200mL concentrated sulfuric acid (98%) at 50°C In the middle, the rotation speed is 400r / min, vigorously stirred for 15min, the reaction solution is poured into 7 time...

Embodiment 3

[0034] A preparation method for self-cleaning functional down, comprising the following steps:

[0035] (1) Preparation of photodegradation system: Weigh 70g of sulfonated polyether ether ketone and dissolve it in 500ml of water, and heat it to 50°C in an ultrasonic environment to accelerate dissolution; weigh 56g of silk fibroin polypeptide powder (particle size 50μm, purity greater than 95%) Dissolve in 500ml of cold water and fully swell for 3 hours, then heat to 70°C to dissolve. Under the condition of 70°C, the two solutions were fully stirred and mixed, and HCl was added to control the pH to 5.5 to prepare a photodegradation system;

[0036] The preparation method of sulfonated polyether ether ketone is: dry polyether ether ketone (Victrex, 450G) pellets at 100°C under vacuum for 6h, then weigh 4g and dissolve in 200mL concentrated sulfuric acid (98%) at 50°C , the rotation speed is 400r / min, stir vigorously for 15min, pour the reaction solution into 8 times the volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com