Polythene glass fiber winding structure wall tube stock and production method thereof

A structural wall pipe material and production method technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., to achieve good alkali resistance, reduce consumption, and reduce internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

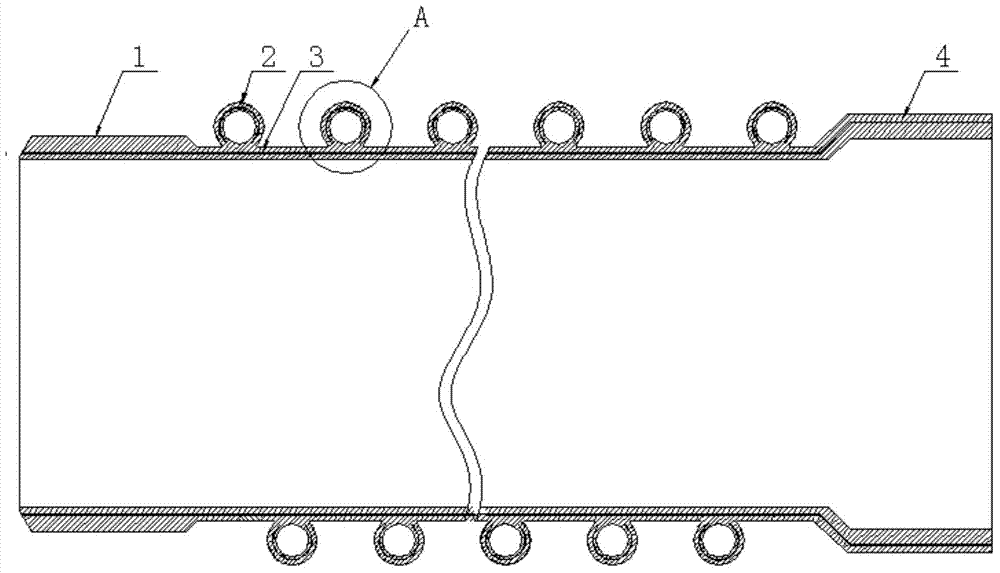

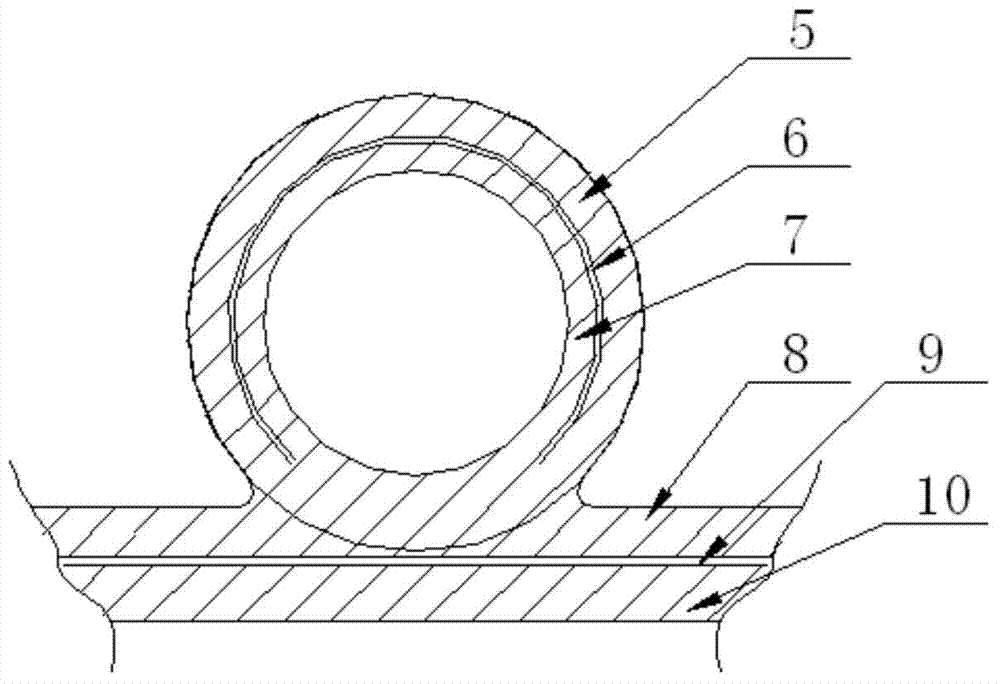

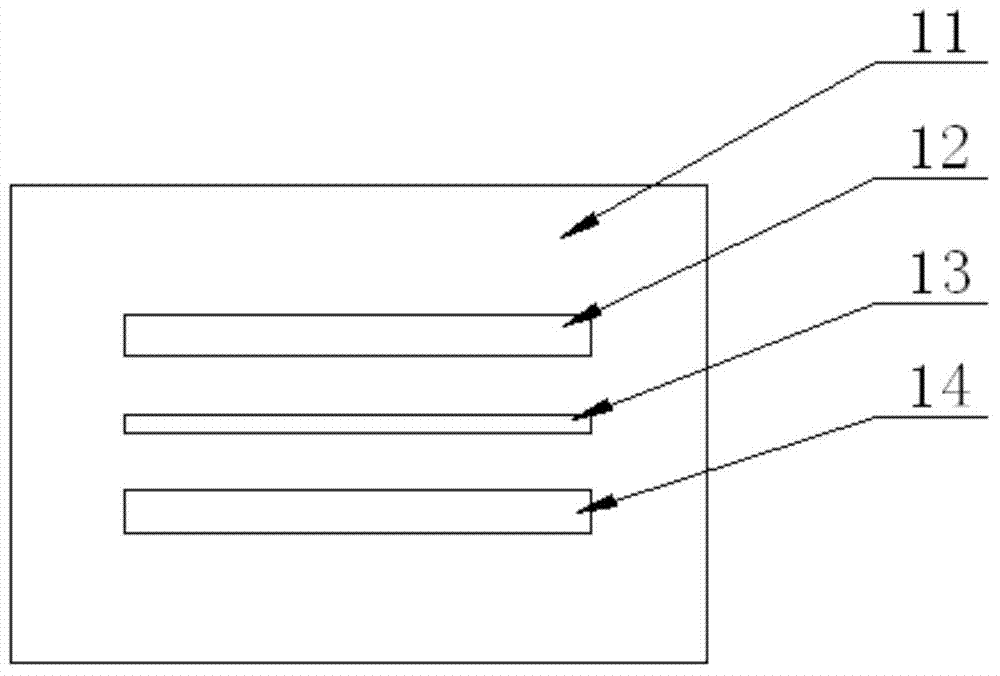

[0032] A polyethylene glass fiber winding structural wall pipe, which is composed of an inner wall layer 3 and an outer wall layer 2, and its innovation is that the inner wall layer is made of an upper sheet-shaped polyethylene strip 8 and a lower sheet-shaped polyethylene strip 10. The composite material tape formed by the glass fiber material tape 9 is spirally wound on the drum mold, and the edges of each adjacent composite tape are overlapped and fused to form a continuous solid wall tube; the outer wall layer is composed of the outer tubular polyethylene strip 5, the inner tubular The middle of the polyethylene strip 7 is covered with the glass fiber material strip 6 spirally wound on the outer surface of the inner wall layer to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com