LED lamp and manufacturing method thereof

A technology of LED lamps and LED light sources, applied in cooling/heating devices of lighting devices, lighting and heating equipment, point light sources, etc., can solve the problems of large investment in molds, complicated lamp body processing technology, and the weight of the whole lamp, etc., to achieve Less investment in equipment and molds, easy mass production, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing:

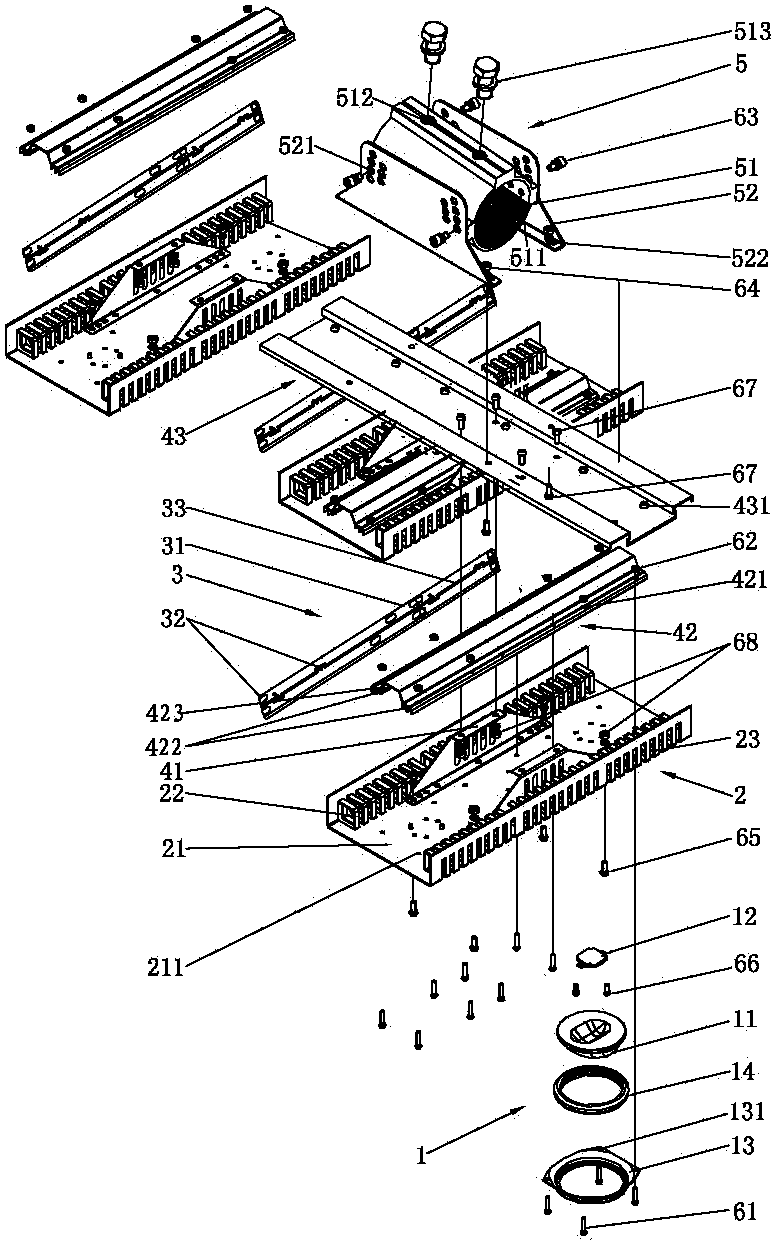

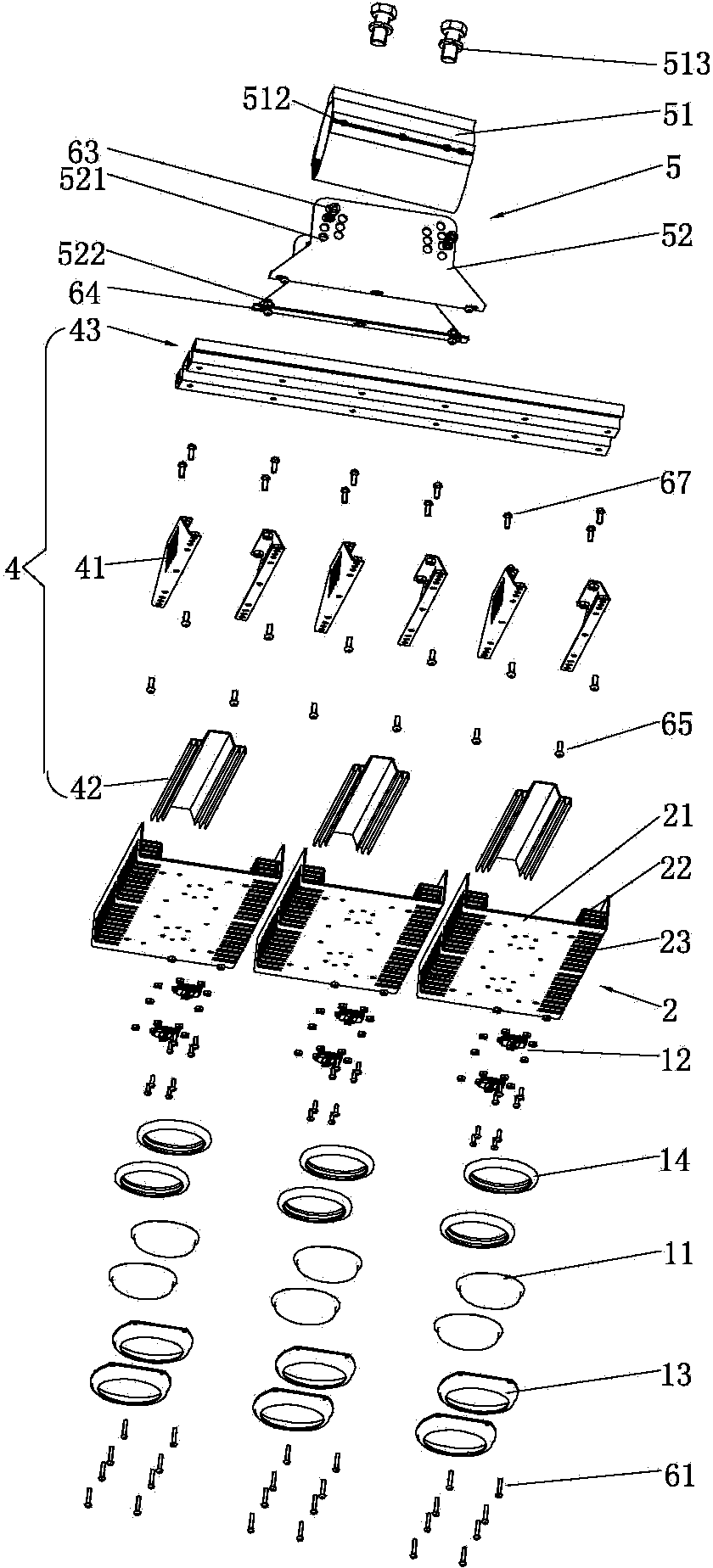

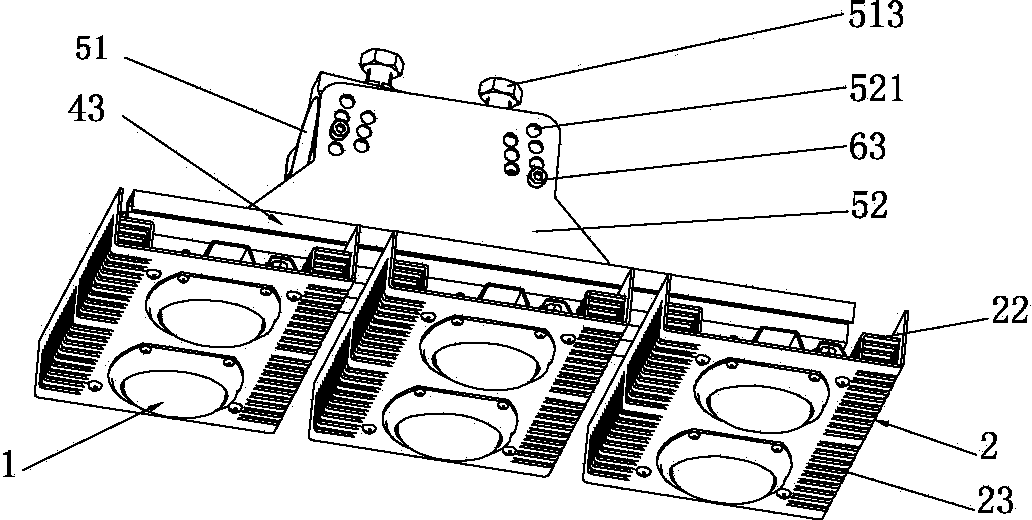

[0035] see Figure 1 ~ Figure 3 As shown, the LED lamp includes a light source module 1, a heat sink 2 and a power supply assembly 3, wherein: the outer surface of the heat sink 2 is connected to the light source module 1, and the inner surface of the heat sink 2 is connected to the light source module 1 through the connection assembly 4. Connected to the light pole fixing component 5, the light source module 1, heat sink 2 and power supply component 3 are encapsulated by a sealing material to form a sealed space.

[0036] In this embodiment, the heat sink 2 is formed by U-shaped frame 21, a plurality of parallel L-shaped cooling fins 22 punched and stretched at the corners of U-shaped frame 21, and the L-shaped cooling fins 22 are stretched on the U-shaped frame. It is composed of several cooling grooves 23 formed on the frame 21 and connected with the outside w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com