Gas sensor

A gas sensor and shell technology, applied in the field of online monitoring, can solve the problems of high integration, high intelligence, complex installation, and large maintenance that do not meet the needs of smart grids, and achieve the effects of low cost, space saving, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

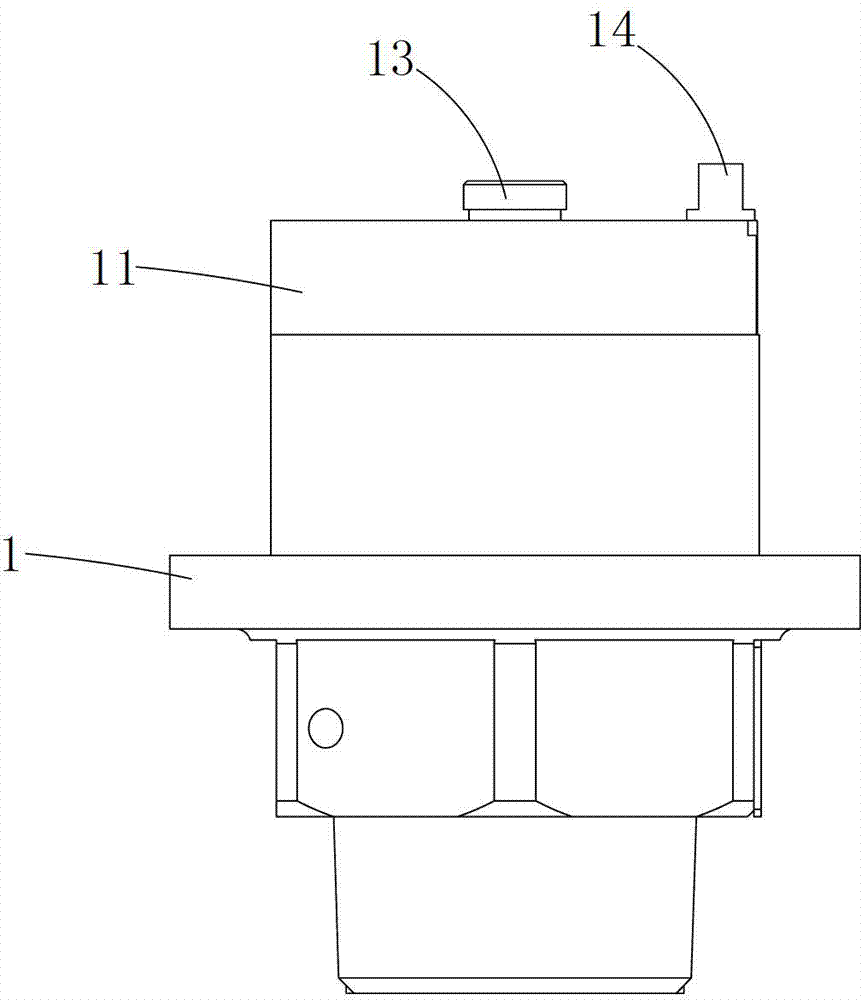

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

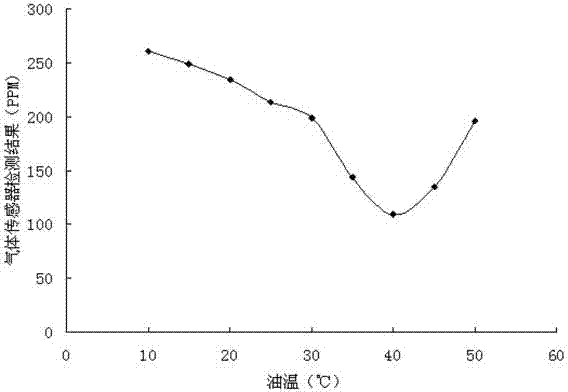

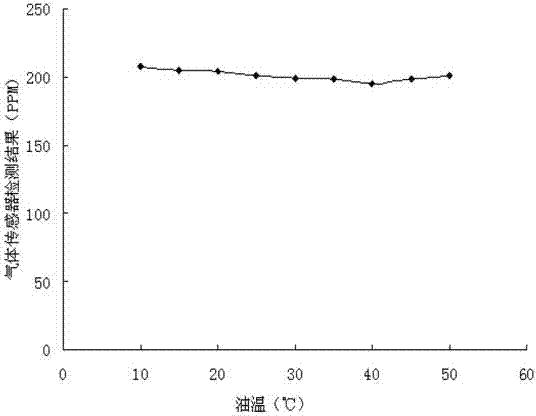

[0028] Such as figure 1 and figure 2 As shown, a gas sensor according to an embodiment of the present invention includes a housing 1 with an inner cavity 10, a composite oil-gas separation membrane 2, a gas sensor 3, a temperature and humidity detection device 4, a built-in temperature probe 5, and a humidity control unit 6 . The composite oil-gas separation membrane 2, the gas sensor 3, the temperature and humidity detection device 4, the built-in temperature probe 5 and the humidity control unit 6 are all installed in the inner cavity 10 of the housing 1, forming a gas sensor with the housing 1, with a height Integrated, it can complete the accurate detection of fault gas, moisture and oil temperature in insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com