A test method for through-silicon via adapter board

A test method and adapter board technology, applied in the direction of the measuring device shell, etc., can solve problems such as damage, affecting packaging quality, holding and testing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention will be described in detail below in conjunction with the accompanying drawings, but this embodiment is not limited to the invention. The structural, method or functional changes made by those skilled in the art based on this embodiment are all included in the present invention. Within the scope of protection.

[0013] A test method for a through silicon via transfer board includes the following steps:

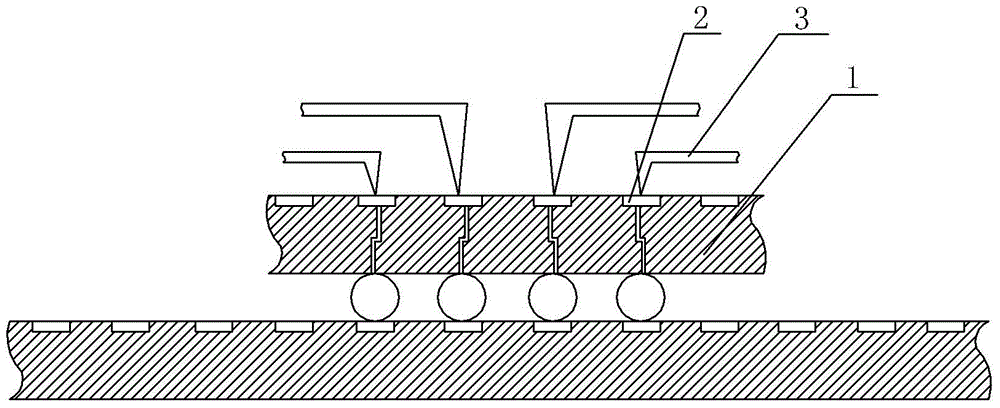

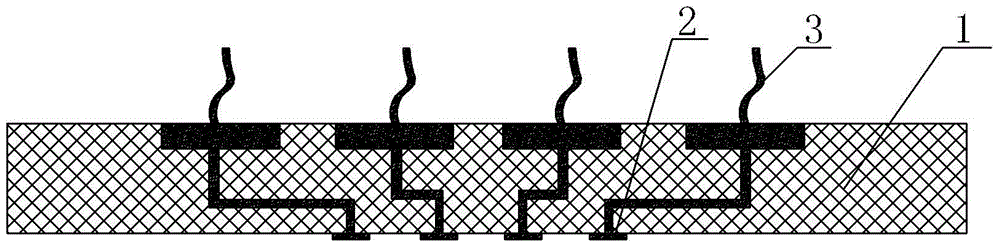

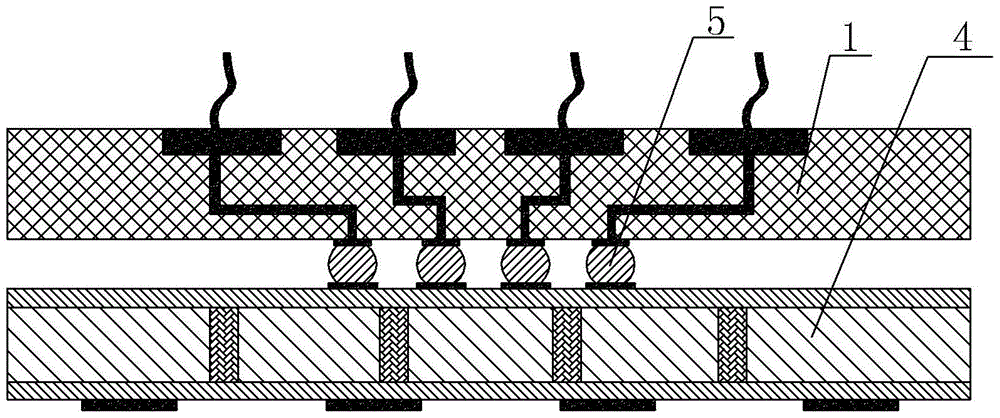

[0014] see figure 2 , (1). Preparation of the test adapter board. Prepare a pressure solder joint (pad) 2 on the test adapter board 1, and use the probe lead 3 to lead the pad out of the other side of the test adapter board 1; see image 3 (2). Use temporary welding to physically connect the bumps 5 (solder balls) on the TSV adapter board 4 to the test adapter board 1;

[0015] see Figure 4 , (3). Set the test adapter board 1 on both sides of the TSV adapter board 4 correspondingly, and use the probe leads 3 on the test adapter board 1 to connect the pads on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com